-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

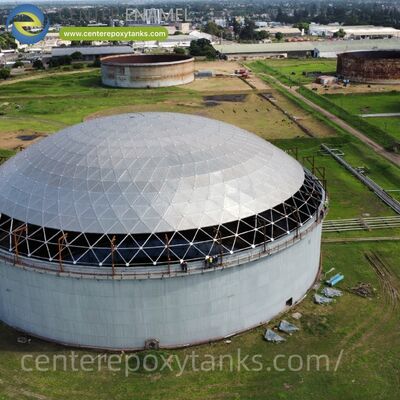

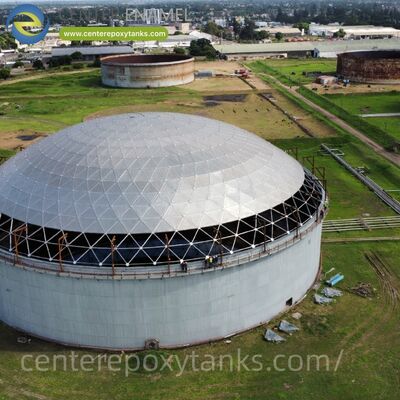

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Bolted Steel Tanks as Silo Tanks: High-Strength GFS Solutions for Industrial and Agricultural Bulk Storage

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Bolted Steel Tanks as Silo Tanks: High-Strength GFS Solutions for Industrial and Agricultural Bulk Storage

In the demanding sectors of industrial processing and large-scale agriculture, the storage of bulk solids requires a vessel that can withstand extreme vertical pressure and constant surface abrasion. Glass-Fused-to-Steel (GFS) Tanks have emerged as the premier choice for silo applications. By fusing molten glass with high-strength steel at temperatures exceeding 800°C, these tanks offer a surface hardness that is impervious to the scratching and scouring of moving grains, minerals, or powders.

Product Introduction: The GFS Silo Advantage

Our Glass-Fused-to-Steel Tanks are engineered specifically for silo service where material flow is constant. The "Glass-Fused-to-Steel" process creates a chemical and physical bond that combines the strength and flexibility of steel with the inertness and hardness of glass. These silos are modular, consisting of factory-coated panels bolted together on-site with high-grade fasteners and specialized sealants, ensuring a structure that is both corrosion-free and structurally resilient.

Product Application: Diverse Bulk Handling

GFS Silo Tanks are versatile units designed for a wide range of high-wear applications:

Agricultural Harvests: Secure storage for wheat, corn, and soybeans, protecting against moisture and pests.

Industrial Minerals: Containment for abrasive materials like cement, fly ash, lime, and mineral ores.

Biomass and Energy: Efficient storage for wood pellets and organic feedstocks.

Food Processing: Hygienic holding for flour, sugar, and other human-consumption ingredients.

Product Advantages: Hardness and Longevity

The primary advantage of a GFS Silo is its surface durability:

Superior Abrasion Resistance: The glass coating has a Mohs hardness that exceeds most industrial granular solids, ensuring the interior remains scratch-free even after years of high-frequency loading.

Corrosion-Free Performance: The inert glass barrier is immune to the acids and moisture found in organic grains and industrial chemicals.

Optimal Flow Dynamics: The ultra-smooth, "glass-like" finish reduces wall friction, facilitating mass flow and preventing "rat-holing" or material bridging.

Hygienic and Easy to Clean: The non-porous surface prevents bacterial growth and is easily sanitized between different material batches.

Customization: Geodesic Domes and Integrated Design

To provide a complete storage solution, we offer extensive customization focused on environmental protection and process integration:

Aluminum Dome Roofs: We integrate Aluminum Dome Roofs to provide a maintenance-free, weather-tight cover. The high reflectivity of the aluminum dome minimizes heat gain in the silo headspace, preventing the condensation that leads to material clumping.

Specialized Discharge Systems: We design custom hopper bottoms (conical bases) with specific angles to ensure the complete discharge of even the most difficult-to-flow powders.

Monitoring Integration: Silos can be equipped with integrated level sensors, temperature cables, and aeration manifolds to maintain the quality of stored assets.

Industry Standards and Risk Assessment

Safety is paramount in silo construction. Our GFS tanks are designed according to rigorous international standards, including AWWA D103, ISO 28765, and OSHA safety guidelines. Each project undergoes a detailed risk assessment, including seismic analysis and wind load calculations, to ensure the structural integrity of the vertical column under full capacity.

Product Installation and Maintenance

Rapid Modular Installation

The bolt-together nature of GFS panels eliminates the need for on-site welding or painting. Using a "top-down" jacking system, the silo is assembled at ground level and lifted ring-by-ring. This method significantly reduces installation time and improves site safety.

Maintenance and Operational Interruption

Because the glass coating is fused at a molecular level, it does not peel or require repainting. This results in an economical long-term solution with near-zero maintenance, ensuring that your facility avoids costly operational interruptions for tank repairs.

Project Cases: Proven Performance

Our GFS technology is utilized in critical infrastructure worldwide, as seen in these non-fictitious examples:

Sichuan Chengdu Wastewater Treatment Plant Project: This project utilized 16 units of tanks, showcasing the ability to handle massive volumes and frequent operational cycles in a large-scale facility.

Saudi Municipal Sewage and Industrial Waste Project: In a region of extreme heat and environmental stress, 5 units of these tanks provide a durable, corrosion-free containment solution.

Hebei Municipal Water and Sewage Infrastructure Project: This project involved 1 unit of a high-integrity bolted tank, proving the reliability and efficiency of the bolted GFS system for essential public utility service.

Company Advantages: Why Choose Our GFS Solutions?

As a leader in the storage industry, we provide more than just a tank—we provide a specialized engineering solution. Our core competitiveness lies in our factory-controlled manufacturing process, ensuring that every panel meets the highest quality checks before shipping. With the combination of high-strength steel, abrasive-resistant glass coating, and the advanced protection of Aluminum Dome Roofs, we deliver a storage system that is built to last.