-

Glass Fused To Steel Tanks (422)

-

Stainless Steel Tanks (433)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (963)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (350)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

|

Detail Information |

|||

Product Description

Welded Steel Tanks for Crude Oil Storage Tanks with Internal Floating Roofs: Prevents Explosive Gas Build-Up Inside the Shell

In the high-stakes world of heavy hydrocarbon management, fire prevention and explosion mitigation are the most critical design parameters. Welded Steel Tanks for Crude Oil Storage Tanks with Internal Floating Roofs are specifically engineered to address the inherent volatility of unrefined petroleum. Crude oil naturally contains a mixture of light-end gases, such as methane and ethane, which can rapidly vaporize and create a hazardous atmosphere. This specialized tank design is essential because it prevents explosive gas build-up inside the shell, thereby safeguarding the facility, the personnel, and the surrounding environment from the catastrophic risks associated with vapor ignition.

Eliminating the Source of Ignition Hazards

The primary safety mechanism of Welded Steel Tanks for Crude Oil Storage Tanks with Internal Floating Roofs is the management of the vapor space, or "ullage." In a standard fixed-roof tank, the area above the crude oil becomes saturated with heavy, flammable vapors. If the mixture of these vapors and oxygen reaches the Lower Explosive Limit (LEL), any static discharge or spark can result in an explosion. The internal floating roof (IFR) effectively solves this by floating directly on the surface of the crude oil. By eliminating the air gap, the system ensures there is no space for vapors to accumulate, which directly prevents explosive gas build-up inside the shell.

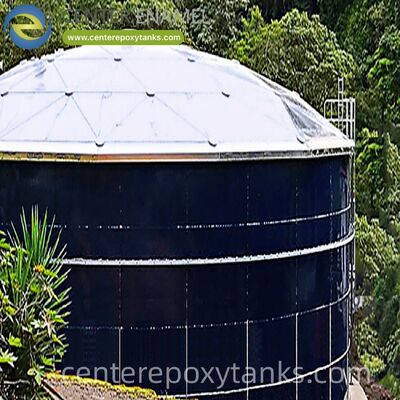

To maximize the safety and longevity of these tanks, the addition of an Aluminum Dome Roof is highly recommended. While the internal floating roof manages the hazardous gases at the liquid surface, the Aluminum Dome Roof provides a superior, non-sparking external cover. The geodesic design of the Aluminum Dome Roof offers a clear-span interior without the need for support columns. This is a vital safety feature for crude oil storage; columns in traditional tanks often penetrate the floating roof, creating potential leak points for vapors to escape. By removing these penetrations, the combination of an IFR and an aluminum dome creates a truly sealed environment that is far more effective at preventing the accumulation of explosive mixtures.

Superior Durability and Weather Protection

Welded Steel Tanks for Crude Oil Storage Tanks with Internal Floating Roofs must withstand the corrosive nature of crude oil, which often contains sulfur and moisture. A fully welded steel shell provides the necessary structural thickness and seamless construction to prevent leaks. When paired with an Aluminum Dome Roof, the entire system becomes nearly maintenance-free. Aluminum is naturally resistant to the corrosive hydrogen sulfide gases often found in crude oil "sour" environments. Furthermore, the dome protects the internal floating roof from heavy rain and snow loads. If water were to accumulate on an internal floating roof, it could cause the deck to tilt or sink, breaking the vapor seal and leading to a dangerous gas release. The Aluminum Dome Roof acts as a permanent umbrella, ensuring the internal safety mechanisms remain dry and fully operational to continue their mission of preventing explosive gas build-up inside the shell.

Application Areas

The extreme safety requirements of crude oil handling make these tanks essential in the following areas:

Upstream Production Sites: Storing raw crude immediately after extraction before pipeline transport.

Crude Oil Tank Farms: Managing massive volumes of oil near refineries where safety perimeters are critical.

Strategic Oil Reserves: Providing long-term, low-maintenance storage for national energy security.

Coastal Import Terminals: Where the combination of a welded steel shell and an Aluminum Dome Roof offers the best protection against seismic activity and salt-water corrosion.

Project Cases: Demonstrated Excellence in Safety Infrastructure

Our history of successful project delivery confirms our ability to manufacture and install the highest quality containment systems. The following cases represent our expertise in providing clear-span and high-integrity covers:

Hebei Province, Silo Cover Project: Provided specialized clear-span structural covers for 5 units.

Guangdong Province, Drinking Water Supply Base: Delivered and installed durable containment covers for 6 units.

Jiangsu Province, Fire Water Storage Base: Successfully completed the installation of robust safety reserves consisting of 3 units.

Company Advantage and Comprehensive Service

Center Enamel is a global leader in the engineering of high-hazard storage solutions. Our approach to Welded Steel Tanks for Crude Oil Storage Tanks with Internal Floating Roofs is built on technical precision and comprehensive support:

Safety-Centric Engineering: We design tank systems specifically to eliminate vapor pockets and static risks, often integrating Aluminum Dome Roofs to ensure a column-free, high-security internal environment.

Advanced Welding Technology: Our fabrication utilizes precision automated welding to ensure the steel shell is completely seamless and capable of handling high hydrostatic loads.

Turnkey Installation Support: We provide specialized technical supervisors for the complex assembly of internal floating decks and geodesic domes, ensuring that every seal and joint is airtight to prevent explosive gas build-up inside the shell.

Conclusion

Safety is the non-negotiable priority in crude oil storage. Welded Steel Tanks for Crude Oil Storage Tanks with Internal Floating Roofs provide the most effective barrier against the formation of hazardous atmospheres. By choosing a system that prevents explosive gas build-up inside the shell, operators protect their most valuable assets and the lives of their workers. When this technology is enhanced by the structural advantages of an Aluminum Dome Roof, it results in a storage solution that is unmatched in durability, safety, and long-term performance.