-

Glass Fused To Steel Tanks (469)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (345)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

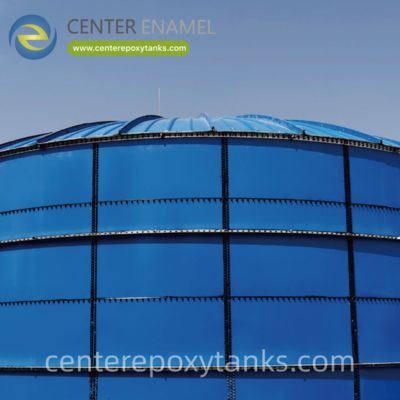

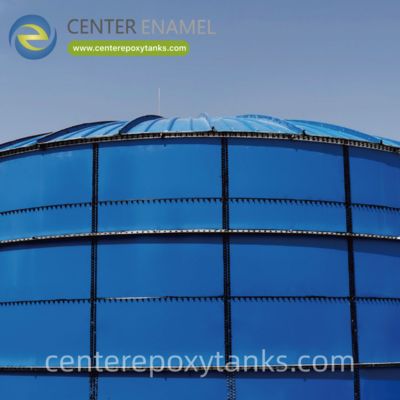

FBE Coated Tank for an Industry Park Wastewater Treatment Plant: A cost-effective, durable solution for complex waste streams.

| Place of Origin: | CHINA |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W20180508003 |

| Minimum Order Quantity: | 1 SET |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates;wooden pallets and wooden box |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | CHINA | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W20180508003 |

| Coating Color: | Dark Green, Or Customizing Colors | Holiday Test: | >1500V |

| Installation: | By Jacking Machine Or Steel Pole, Fast In Installation | Permeability: | Gas / Liquid Impermeable |

| Steel Grade: | ART 310 | Applications: | Water , Waste Water, Digester , Reactor , Grain , Sludge , Chemicals |

| Highlight: | FBE coated wastewater treatment tank,durable FBE epoxy tank,industrial wastewater treatment plant tank |

||

Product Description

FBE Coated Tank for an Industry Park Wastewater Treatment Plant: A cost-effective, durable solution for complex waste streams.

Industry Park Wastewater Treatment is uniquely challenging as it must manage a complex and highly variable blend of effluent from numerous different tenants, including chemical, textile, and light manufacturing facilities. The resulting complex waste streams often feature fluctuating ![]() levels, high

levels, high ![]() , and various corrosive chemicals. Containment must be a cost-effective, durable solution that can withstand this aggressive and unpredictable environment over decades of service. The Fusion Bonded Epoxy

, and various corrosive chemicals. Containment must be a cost-effective, durable solution that can withstand this aggressive and unpredictable environment over decades of service. The Fusion Bonded Epoxy ![]() Coated Tank is engineered for this role, providing a cost-effective, durable solution for complex waste streams in industrial parks.

Coated Tank is engineered for this role, providing a cost-effective, durable solution for complex waste streams in industrial parks.

The Challenge of Complex, Variable Waste Streams

Containment infrastructure in an Industry Park Wastewater Treatment Plant faces critical demands due to the nature of the influent:

Chemical Heterogeneity ![]() : The effluent is a mixture of diverse industrial processes, making its chemical profile unpredictable. This requires a durable solution that offers broad chemical resistance against various acids, bases, and salts.

: The effluent is a mixture of diverse industrial processes, making its chemical profile unpredictable. This requires a durable solution that offers broad chemical resistance against various acids, bases, and salts.

Corrosion from ![]() Fluctuation: The neutralization and equalization processes are vital but often lead to rapid cycling between high and low

Fluctuation: The neutralization and equalization processes are vital but often lead to rapid cycling between high and low ![]() , demanding a tank lining with superior resilience to chemical shock.

, demanding a tank lining with superior resilience to chemical shock.

High Volume and Flow Variability: Industrial parks generate large, continuous volumes of wastewater with wide diurnal flow variations. The containment vessel must be a structurally durable solution capable of safely managing these massive hydraulic loads.

Cost Efficiency ![]() : Given the scale of industrial park infrastructure, the selected containment solution must be cost-effective, offering a long service life and minimal maintenance requirements to ensure low total cost of ownership.

: Given the scale of industrial park infrastructure, the selected containment solution must be cost-effective, offering a long service life and minimal maintenance requirements to ensure low total cost of ownership.

A reliable industrial park solution must be a cost-effective, durable solution for complex waste streams that guarantees chemical resistance and operational longevity.

The FBE Solution: Cost-Effective Durability for Industry Parks

Center Enamel’s Fusion Bonded Epoxy Bolted Steel Tanks are engineered to provide the definitive solution for Industry Park Wastewater Treatment:

Permanent Chemical Resistance ![]() : The factory-applied, molecularly bonded

: The factory-applied, molecularly bonded ![]() coating provides a dense, inert barrier offering superior chemical resistance. This makes it a durable solution built to withstand the diverse and corrosive chemical components found in complex waste streams.

coating provides a dense, inert barrier offering superior chemical resistance. This makes it a durable solution built to withstand the diverse and corrosive chemical components found in complex waste streams.

Superior Structural Strength: Constructed from high-tensile, factory-engineered steel, ![]() tanks offer certified structural integrity. This ensures the tank is a durable solution capable of managing the immense hydrostatic pressure of large-volume equalization and treatment basins.

tanks offer certified structural integrity. This ensures the tank is a durable solution capable of managing the immense hydrostatic pressure of large-volume equalization and treatment basins.

Rapid Deployment and Scalability ![]() : The modular, bolted design allows for significantly faster construction than traditional concrete, minimizing labor costs and project timelines. This makes it a highly cost-effective solution for establishing or rapidly expanding treatment capacity.

: The modular, bolted design allows for significantly faster construction than traditional concrete, minimizing labor costs and project timelines. This makes it a highly cost-effective solution for establishing or rapidly expanding treatment capacity.

Long Service Life: The high-performance ![]() coating is designed for a service life exceeding 30 years, reducing the need for costly maintenance and replacements, thereby reinforcing its cost-effective nature.

coating is designed for a service life exceeding 30 years, reducing the need for costly maintenance and replacements, thereby reinforcing its cost-effective nature.

Ideal for All Process Stages: ![]() tanks are suitable for every unit operation in the industrial park plant, including equalization, neutralization, primary clarification, and biological treatment

tanks are suitable for every unit operation in the industrial park plant, including equalization, neutralization, primary clarification, and biological treatment ![]() .

.

Project Case Studies: FBE Tanks in Complex Industrial Infrastructure

Center Enamel has provided cost-effective, durable solution containment for major industrial and high-volume wastewater projects managing complex and aggressive effluent.

| Project Description | Project Scale and Quantity |

| Sinopec Group Fujian Quanzhou Chemical Wastewater Project | We supplied a high-performance solution consisting of 4 units with a total capacity of 12,080 cubic meters, deployed for the secure, durable containment of large volumes of complex chemical and oil-related industrial effluent. |

| Zhejiang Shaoxing Chemical Wastewater Treatment Project | A major industrial installation consisting of 2 units with a total capacity of 11,609 cubic meters, providing a cost-effective solution for large-scale, complex chemical flows under stringent regulatory control. |

| Huadong Medicine Zhejiang Hangzhou Pharmaceutical Plant Wastewater Treatment Project | This critical infrastructure utilized 6 units with a total capacity of 18,114 cubic meters, demonstrating the required durability and chemical resilience for complex pharmaceutical discharge. |

Conclusion: Securing Industrial Resilience

The effective management of Industry Park Wastewater requires a foundation that is both chemically robust and economically viable. The Fusion Bonded Epoxy Coated Tank, with its permanent chemical resistance and rapid construction, delivers a definitive cost-effective, durable solution for complex waste streams. This investment protects the entire treatment system from corrosive failure, ensures operational continuity, and provides industrial parks with a sustainable, durable solution for long-term environmental compliance.

To deploy a cost-effective, durable solution engineered for the complex waste streams of an Industry Park Wastewater Treatment Plant, choose Center Enamel's FBE Coated Tanks. Contact us today to secure your essential infrastructure.