-

Glass Fused To Steel Tanks (463)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (210)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

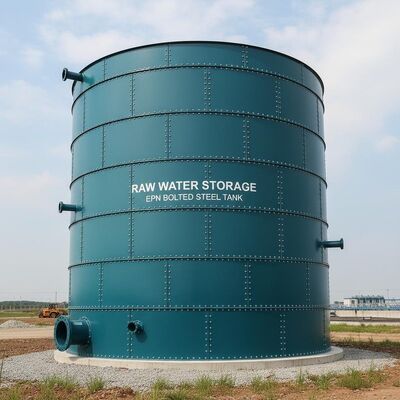

Epoxy Bonded Steel Bolted Tanks as Raw Water Tank: Durable primary storage for untreated water before filtration or treatment.

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W201691123005 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W201691123005 |

| Steel Plates Thickness: | 3mm To 12mm , Depends On The Tank Structure | Corrosion Integrity: | Excellent |

| Chemical Resistance: | Excellent | Capacity: | 20 M3 To 18,000 M3 |

| Service Life: | ≥30 Years | Permeability: | Gas / Liquid Impermeable |

| Highlight: | Epoxy bonded steel water tank,Raw water storage bolted tank,Durable fusion bonded epoxy tank |

||

Product Description

Epoxy Bonded Steel Bolted Tanks as Raw Water Tank: Durable primary storage for untreated water before filtration or treatment.

Raw water—sourced from rivers, lakes, boreholes, or rainwater—is the fundamental starting point for municipal, industrial, and agricultural water systems. However, untreated water is rarely benign. It often carries a complex load of suspended solids, organic matter, dissolved minerals, and varying microbial populations. Depending on the source, raw water can be surprisingly corrosive or abrasive, presenting a significant challenge to primary storage infrastructure. As the first stage in the treatment chain, a raw water tank must be exceptionally durable to ensure that the water remains securely contained before it reaches filtration or purification units.

Traditional storage methods, such as concrete basins or standard painted steel tanks, often struggle with the unpredictable nature of raw water. Concrete is susceptible to "soft water" leaching or chemical attack from minerals, while field-applied coatings on welded tanks frequently fail due to the abrasive nature of raw silt and grit. To provide a high-integrity solution, engineers have increasingly turned to Epoxy Coated Tanks, specifically Epoxy Bonded Steel Bolted Tanks. These vessels provide a factory-engineered, robust barrier that is designed to withstand the varying chemical and physical characteristics of raw water.

The Challenges of Storing Untreated Raw Water

A primary storage vessel for raw water must be engineered to handle several distinct forms of environmental and physical stress:

Abrasive Sediment and Grit: Raw water often contains sand, silt, and other suspended solids. During filling or mixing, these particles can be abrasive. The tank lining must possess high scratch and impact resistance to prevent the structural steel from being exposed.

Variable Chemical Profiles: Water from underground aquifers or surface runoff can have fluctuating pH levels and high mineral content. An Epoxy Bonded Steel Bolted Tank provides a chemically inert interior that prevents internal oxidation and "pitting" of the steel panels.

Microbial and Algal Growth: Untreated water is rich in nutrients that support the growth of algae and biofilms. The smooth, non-porous finish of the epoxy barrier inhibits biological attachment, making the tank easier to clean and preventing the buildup of organic sludge.

External Environmental Corrosion: Raw water tanks are often the first structure in a treatment plant and are fully exposed to the elements. The external coating must be UV-stable and resistant to humidity to prevent structural thinning over decades of service.

By providing a molecularly bonded barrier, Epoxy Coated Tanks ensure that the primary reservoir remains a stable and low-maintenance asset for the entire treatment facility.

Engineering Excellence: The Fusion Bonded Epoxy Barrier

The reliability of these tanks is rooted in the Fusion Bonded Epoxy (FBE) manufacturing process. Conducted entirely within a controlled factory environment, this process ensures a level of quality that is impossible to replicate with on-site painting.

The process begins with the precision preparation of high-strength steel panels. Each panel is grit-blasted to achieve a near-white finish, creating an ideal mechanical anchor profile. A high-grade, thermosetting epoxy powder is then electrostatically applied. The panels are cured in specialized ovens at extreme temperatures, causing the epoxy to melt, flow, and undergo a chemical cross-linking reaction with the steel substrate.

This results in a dense, uniform, and incredibly tough barrier that is molecularly fused to the steel. Because the panels are coated before assembly, every edge and pre-punched bolt hole is fully encapsulated. In the bolted system, these panels are joined on-site using specialized high-strength fasteners and industrial-grade sealants, creating a liquid-tight structure that is immune to the environmental and chemical stresses of raw water storage.

Protecting Water Quality with Aluminum Dome Roofs

In raw water management, protecting the source water from external contamination and evaporation is a strategic priority. This is why the integration of Aluminum Dome Roofs has become a standard for high-performance primary storage:

Prevention of Contamination: Raw water is already untreated; adding wind-blown debris, dust, or animal waste only increases the burden on the downstream filtration system. Aluminum Dome Roofs provide a secure cover that maintains the initial quality of the source water.

Algae Control: By blocking sunlight, the aluminum dome eliminates the primary driver of algae growth. This is critical for preventing biological matter from clogging intake pipes and filters further down the treatment line.

Maintenance-Free Performance: Raw water tanks are often located in remote areas. While a steel roof would require constant maintenance to prevent rust, aluminum is naturally resistant to the elements, providing a maintenance-free cover for the life of the tank.

Structural Strength: The geodesic design of the aluminum dome provides immense structural strength while remaining lightweight. This clear-span architecture maximizes the usable volume of the tank and allows for the easy installation of level monitoring equipment.

Modular Versatility and Rapid Installation

For a treatment facility or industrial plant, the ability to rapidly establish storage is vital. One of the primary benefits of the bolted tank system is its speed of installation. Because the components are prefabricated, the on-site assembly is fast and efficient, requiring no on-site welding or extensive scaffolding. This allows projects to proceed quickly, even in challenging terrain.

Furthermore, the modular nature of the Epoxy Bonded Steel Bolted Tank allow for future flexibility. If the demand for water increases, these tanks can often be heightened by adding more rings of panels. This modularity ensures that the initial infrastructure investment remains a long-term asset that can grow with the facility's needs.

Project Cases: Proven Performance in Water Infrastructure

The following non-fictitious projects highlight the successful implementation of our Epoxy Coated Tanks in demanding large-scale water and utility environments:

Hebei Municipal Water and Sewage Infrastructure Project: This project utilized a high-integrity bolted tank to support regional water distribution. The installation included 1 unit of tank, providing a reliable and low-maintenance solution for primary water management.

Sichuan Chengdu Wastewater Treatment Plant Project: To support the massive utility needs of a major metropolitan area, this project deployed a high-capacity system featuring 16 units of tanks. This case demonstrates the structural stability and modular efficiency required for large-volume liquid storage.

Saudi Municipal Sewage and Industrial Waste Project: Operating in extreme temperatures, this project required tanks that could resist both internal water chemistry and external environmental stress. The facility utilized 5 units of tanks, ensuring a secure and corrosion-free solution for municipal-scale water handling.

Conclusion: A Durable Standard for Raw Water Storage

The effective management of raw water requires infrastructure engineered for durability, abrasion resistance, and long-term structural integrity. The Epoxy Bonded Steel Bolted Tank represents the most advanced solution for primary water containment.

By providing a factory-fused barrier that resists internal and external corrosion, and by incorporating the advanced protection of Aluminum Dome Roofs, these tanks ensure that raw water is stored with absolute security before treatment. They offer a high-strength, low-maintenance, and scalable solution that protects the entire water treatment chain.