-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Bolted Steel Industrial Water Tanks for Fire Water Storage: The Ultimate Solution for Fire Protection Needs

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

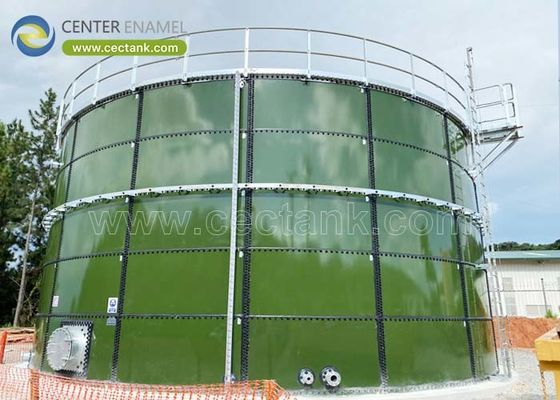

Bolted Steel Industrial Water Tanks for Fire Water Storage: The Ultimate Solution for Fire Protection Needs

Fire safety is a critical consideration for industrial facilities worldwide, as it directly impacts not only the safety of personnel but also the preservation of valuable assets and infrastructure. In industries where the risk of fire is heightened—such as chemical plants, power stations, oil refineries, and manufacturing plants—adequate fire water storage is essential. To meet these demands, Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) offers Bolted Steel Industrial Water Tanks for Fire Water Storage, designed to provide a reliable and efficient solution for fire protection.

With over 30 years of expertise in manufacturing Glass-Fused-to-Steel (GFS) bolted storage tanks, Center Enamel has become a global leader in providing advanced storage solutions. Our bolted steel water tanks, specifically designed for fire water storage, combine durability, cost-efficiency, and ease of installation, making them the ideal choice for industries in need of a secure and scalable fire protection system.

As a leading storage tank manufacturer worldwide. Center Enamel can provide Glass Lined Steel(GLS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GLS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks Welded Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GLS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Bio gas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

Why Choose Bolted Steel Industrial Water Tanks for Fire Water Storage?

Fire water storage systems must be robust, dependable, and durable to withstand the rigors of constant pressure and extreme weather conditions. Here's why bolted steel tanks are the optimal solution for industrial fire water storage:

1. Durability and Corrosion Resistance

Fire water storage tanks are typically exposed to a variety of environmental factors, including extreme temperatures, UV rays, and exposure to waterborne chemicals. The Glass-Fused-to-Steel (GFS) technology used in our tanks provides a smooth, non-porous surface that offers exceptional resistance to corrosion, ensuring that your fire water storage system remains functional for decades.

The fusion of glass and steel at high temperatures creates a durable coating that prevents rusting, maintains structural integrity, and extends the lifespan of the tank. This makes our bolted steel water tanks the ideal choice for industrial applications where long-term performance is required.

2. Customizable and Scalable

Our GFS bolted steel tanks are modular, which means they can be easily customized and scaled to meet your specific fire water storage needs. Whether you're storing a few thousand liters or several million, we can design and manufacture a tank that meets your exact capacity and spatial requirements.

As your business grows, Center Enamel’s bolted steel tanks can be easily expanded by adding additional modules, allowing for a seamless increase in storage capacity without the need for a complete overhaul of your existing infrastructure.

3. Quick and Easy Installation

One of the key advantages of bolted steel tanks is their quick installation process. Unlike welded or concrete tanks, which require extensive construction and curing time, bolted steel tanks are pre-engineered and assembled on-site in a fraction of the time. This time efficiency reduces operational downtime and helps businesses maintain continuous operations while implementing fire protection systems.

Additionally, the modular design ensures that if any component of the tank needs to be replaced, it can be done without disrupting the entire system, minimizing any potential downtime during maintenance.

4. High Capacity and Load-Bearing Design

Our bolted steel fire water storage tanks are designed to store large volumes of water, with high load-bearing capacity to ensure the structural integrity of the tank, even under pressure. These tanks can hold substantial amounts of water for use in fire fighting systems, ensuring an adequate water supply during emergencies.

This high capacity is essential for industries where large-scale firefighting systems are required, such as power plants, chemical factories, and manufacturing plants.

5. Easy Maintenance and Longevity

The Glass-Fused-to-Steel technology used in our bolted tanks ensures that the tank is highly resistant to wear and tear, reducing the frequency of repairs or replacements. The smooth glass surface not only prevents corrosion but also prevents the buildup of organic matter, which can be common in traditional steel tanks.

Moreover, with the modular construction of our tanks, any damaged part can be easily replaced without the need for significant repairs, ensuring that your fire water storage system continues to function effectively for decades.

6. Environmental Safety and Compliance

At Center Enamel, we understand the importance of complying with local and international safety standards. Our bolted steel tanks are designed to meet AWWA D103 standards, as well as other fire protection regulations. The tanks are built to hold drinking water quality water, making them safe for fire-fighting purposes without contamination concerns.

The corrosion-resistant properties of GFS tanks ensure that stored water remains clean and free from pollutants, thereby reducing the environmental impact of fire water storage systems.

Key Features of Our Bolted Steel Industrial Water Tanks for Fire Water Storage

Durable Glass-Fused-to-Steel Coating: Offers exceptional resistance to corrosion, UV degradation, and chemical exposure.

Modular Construction: Easily expandable to accommodate growing storage needs.

Customizable Size and Shape: Tailored to meet specific capacity requirements for your fire protection system.

Quick and Efficient Installation: Pre-engineered, bolted design allows for rapid assembly on-site, minimizing downtime.

Cost-Effective Maintenance: Designed to last for decades with minimal upkeep and repair costs.

Compliance with Industry Standards: Manufactured according to AWWA D103, NFPA, and ISO standards for fire safety.

High Capacity and Load-Bearing: Engineered to withstand high volumes of water for emergency use.

Applications of Bolted Steel Industrial Water Tanks for Fire Water Storage

Our bolted steel fire water storage tanks are widely used across various industries, including:

1. Chemical and Petrochemical Industries

In chemical and petrochemical plants, where fire hazards are significant due to the flammable nature of the materials involved, a reliable fire water storage system is crucial. Our bolted steel tanks provide the necessary capacity and fire protection capabilities to safeguard both workers and facilities.

2. Power Generation Facilities

Power plants, particularly thermal and nuclear plants, require robust fire protection systems to protect both personnel and critical equipment. Our industrial fire water storage tanks can provide continuous, high-volume water for firefighting systems, ensuring a rapid response during emergencies.

3. Oil Refineries

In the oil and gas industry, where fire risks are high, bolted steel fire water tanks provide safe and effective storage of fire water. Our tanks help refineries comply with stringent fire safety regulations, ensuring that they can meet the demands of fire suppression systems.

4. Manufacturing Plants

Manufacturing plants, especially those dealing with flammable materials or high-energy processes, require dependable fire water storage systems to prevent catastrophic losses in case of a fire. Our bolted steel tanks offer a safe, efficient, and cost-effective solution for fire water storage.

When it comes to fire water storage, Center Enamel offers the most reliable, cost-effective, and durable solutions. Our Glass-Fused-to-Steel bolted tanks provide long-lasting performance, quick installation, and scalability, making them the ideal choice for industries in need of secure fire protection systems.

With our expertise and modular design, Center Enamel ensures that you will have the optimal storage solution to protect your facility against fire risks, reduce operational downtime, and ensure compliance with fire safety standards.

Contact Center Enamel today to discuss your fire water storage requirements and find out how our bolted steel industrial water tanks can safeguard your business for the long term.