-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Glossy Waste Water Storage Tanks / Glass Fused To Steel Municipal Sewage Storage Tank

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W |

| Tank Body Color: | Dark Green / Can Be Customized | Corrosion Integrity: | Excellent |

| Steel Plates Thickness: | 3mm To 12mm , Depends On The Tank Structure | Chemical Resistance: | Excellent |

| Size Of Panel: | 2.4M * 1.2M | Easy To Clean: | Smooth, Glossy, Inert, Anti-adhesion |

| Highlight: | water treatment tank,sewage treatment tank |

||

Product Description

Glass Fused To Steel Municipal sewage storage tank

With the rapid development of global economy, the problem of environmental pollution, especially the treatment of municipal sewage has become a research hotspot in many countries. municipal sewage is the outcome of city development. With the development of urbanization and industrialization, its output has been increasing, and the pollution has become increasingly serious, which has seriously restricted the sustainable development of urban economy.

As a storage tank for municipal sewage treatment, Glass-Fused-to-Steel Tank has become the preferred choice of municipal sewage storage solution in municipal sewage treatment plant of each city.

Why the municipal sewage treatment plant choose Glass-Fused-to-Steel Tank?

The service life is more than 30 years with a lower maintenance, Glass-Fused-to-Steel is two materials - Enamel glaze and steel plate surface are fused together after heat treatment at 850-940℃ and then create a tough and inert bond, which combines the strength of steel with the outstanding chemical and physical corrosion resistance of glass. Then it is easy to install , dismantled, removed and relocated,Glass-Fused-To-Steel tank is assembled by Glass-Fused-To-Steel plate and fixed by self - locking bolt. Then the sealing glue is applied to the joint gap and bolt position to improve airtightness of the tank. Also tank’s color can be customized ,which enable Glass-Fused-to-Steel tank better integrate with the surrounding environment. That is why so many municipal sewage treatment plant choose Glass-Fused-to-Steel Tank as the municipal sewage storage tank.

Glass Fused To Steel Municipal Sewage Storage Tank Specifications

| Coating color | dark blue, dark green, white, and customized |

| A standard steel plate size | effective size 2400mm x 1200 m |

| Steel plates thickness | 3mm - 12mm, depends on the diameter & height |

| Coating thickness | 0.25mm - 0.4mm, two coatings internal and external |

| Acid and alkalinity proof | standard coating suits for PH3 - PH11, special coating suits for PH1 - PH14 |

| Adhesion | 3,450N/cm |

| Elastic | same as steel sheet, around 500KN/mm |

| Hardness | 6.0 Mohs |

| Service life | >30 years |

| Spark test | >1500 V |

| Permeability | gas and liquid impermeable |

| Easy yo clean | smooth, glossy, inert, anti-adhesion |

| Corrosion resistance | excellent! Suitable for wastewater saltwater, seawater, high sulfur crude oil, salt fox, organic and inorganic compounds |

About us

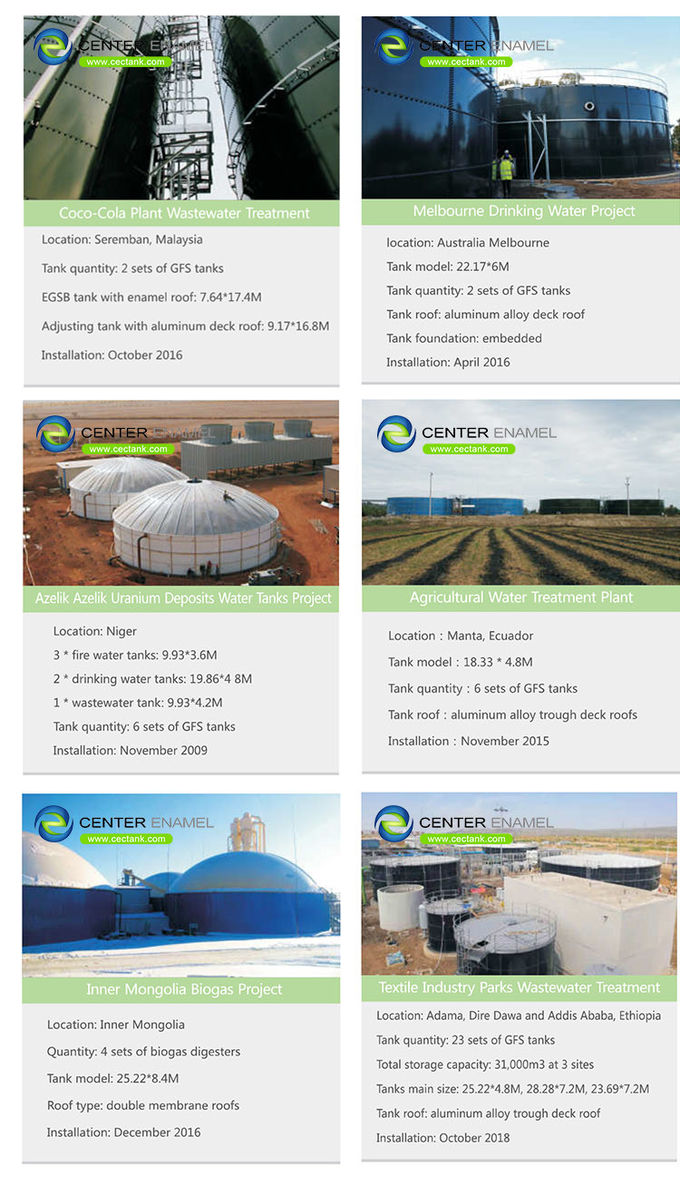

Center Enamel Co., Ltd is not only the first Glass-Fused-to-Steel Tanks manufacturer and supplier in China, but also the most experienced Glass-Fused-to-Steel tanks manufacturer in all of Asia. Center Enamel Glass-Fused-to-Steel tanks engineering & design, product testing and quality system are in strict accordance with AWWA D103-09, OSHA, ISO/EN 28765, NSF61 and NFPA etc. international standards. CEC Glass-Fused-to-Steel tanks are widely used in drinking/potable water, industrial effluents, municipal sewage, bio-energy, landfill leachate, agriculture etc. applications. Until 2018, Center Enamel Glass-Fused-to-Steel tanks have been exported to more than 60 countries including USA, Australia, Canada, Malaysia, Indonesia, Russia, UAE, Panama, India and South Africa etc. The superior product quality and prompt service gain us worldwide recognition.

Project References