-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

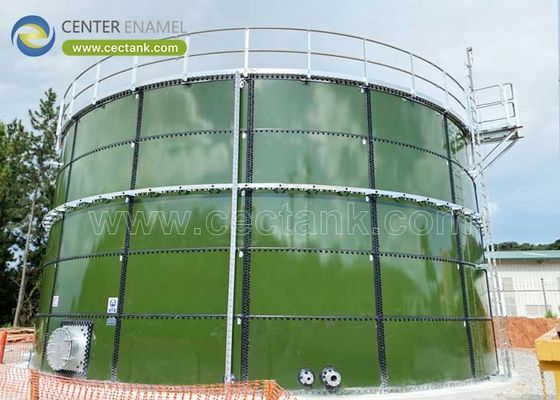

Wastewater Storage Tanks Manufactured in ISO 9001:2008 Quality

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W20160126019 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Wastewater Storage Tanks Manufactured in ISO 9001:2008 Quality

Controlled Facilities: Ensuring Superior Performance and Reliability

In today’s rapidly evolving industrial landscape, the demand for effective and reliable wastewater storage solutions has never been more crucial. Industries across the globe require robust, durable, and high-performance tanks to store wastewater, particularly in industries such as chemical processing, food and beverage, municipal sewage treatment, and biogas plants. To meet these needs, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a leader in the manufacturing of bolted storage tanks, delivers state-of-the-art wastewater storage tanks that are manufactured under the strictest quality control standards, with ISO 9001:2008 certification ensuring the highest levels of performance and reliability.

Why ISO 9001:2008 Quality Control Matters

ISO 9001:2008 is an internationally recognized quality management standard that defines the criteria for a robust quality management system. This certification ensures that organizations maintain a consistent approach to quality across all stages of production, from design and manufacturing to delivery and after-sales service. By adhering to ISO 9001:2008, Center Enamel guarantees that every wastewater storage tank produced is subject to stringent quality control measures, resulting in superior products that meet or exceed global standards.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks Welded Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Biogas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

The benefits of choosing wastewater storage tanks manufactured in ISO 9001:2008 certified facilities include:

Consistency and Reliability: The standard ensures that all products are manufactured using consistent processes, ensuring every tank delivered offers the same high level of reliability.

Continuous Improvement: ISO 9001 emphasizes continuous improvement, encouraging innovation and optimization in the production process to enhance the performance and efficiency of storage tanks.

Customer Satisfaction: By adhering to the standard’s rigorous customer-focused approach, Center Enamel ensures that its tanks consistently meet customer requirements, reducing defects, delays, and the risk of project failure.

Center Enamel’s Commitment to Quality

At Shijiazhuang Zhengzhong Technology Co., Ltd, quality control is not just a process, but a philosophy that permeates every aspect of our business. Since our founding in 1989, we have made quality and innovation our top priorities, positioning us as the most experienced bolted tank manufacturer in Asia. Our ISO 9001:2008 certification is a testament to our unwavering commitment to delivering reliable and durable storage solutions to clients around the world.

Our wastewater storage tanks, including Glass-Fused-to-Steel (GFS) tanks, fusion-bonded epoxy tanks, and stainless steel tanks, are manufactured in our state-of-the-art facilities, where every step of the production process is carefully monitored. From raw materials sourcing and design engineering to welding, assembly, and finishing, all processes are controlled under the ISO 9001:2008 guidelines, ensuring every tank is crafted to perfection.

Key Features of Our Wastewater Storage Tanks

Corrosion Resistance

Our Glass-Fused-to-Steel and fusion-bonded epoxy tanks are renowned for their exceptional corrosion resistance. The fusion of glass or epoxy to steel creates a non-porous, highly durable surface that protects the tank from acidic, alkaline, or chemical-rich wastewater environments. This ensures the tanks maintain their integrity for decades, even in challenging environments.

Customizable Sizes and Designs

Center Enamel manufactures wastewater storage tanks to meet the specific needs of each project. Whether you need small-scale storage or large, high-capacity tanks, our tanks are fully customizable to suit your wastewater management requirements. The bolted design makes installation quick and efficient, and the modular nature allows for easy expansion or modification in the future.

High-Strength Materials

Our tanks are built with high-strength steel that is carefully selected to ensure optimal performance under pressure and in extreme weather conditions. With a Glass-Fused-to-Steel coating, the tanks offer superior durability, maintaining their structural integrity even under the most demanding conditions.

Excellent Sealing Performance

Our tanks are designed to offer excellent sealing performance, preventing leaks and ensuring that stored wastewater is safely contained. This feature is essential in protecting the environment and meeting regulatory standards for wastewater management.

Environmental Protection

Center Enamel’s wastewater storage tanks are built with the environment in mind. Our tanks prevent leaching and contamination, keeping stored wastewater securely contained to protect surrounding ecosystems. The smooth, glass-coated surface also inhibits bacterial growth, ensuring cleaner storage conditions.

Compliance with International Standards

Our ISO 9001:2008 certification ensures that our tanks comply with various international standards, such as AWWA D103-09, NSF/ANSI 61, and ISO 28765, providing customers with the confidence that our tanks meet the highest levels of quality, safety, and reliability.

Proven Success in Global Projects

Over the past three decades, Center Enamel has successfully completed over 30,000 projects in 100+ countries worldwide, including in regions such as the USA, Australia, Canada, Middle East, and Asia. Our wastewater storage tanks have been used in various applications, including municipal wastewater treatment, chemical effluent storage, biogas plants, landfill leachate containment, and more.

Our commitment to quality and our dedication to customer satisfaction have earned us long-term partnerships with global companies like Coca-Cola, Veolia, Sabesp, PetroChina, and Heineken. These partnerships reflect our reputation as a reliable supplier of high-quality wastewater storage tanks, trusted by leading organizations worldwide.

Why Choose Center Enamel for Your Wastewater Storage Needs?

Unmatched Quality: Our ISO 9001:2008 certified manufacturing facilities ensure consistent quality in every tank.

Advanced Engineering: Our tanks are engineered for high performance and long-term durability, designed to withstand a wide range of wastewater environments.

Global Expertise: With over 30 years of experience, Center Enamel has successfully delivered wastewater storage tanks to over 100 countries.

Comprehensive Support: From design to installation and after-sales service, Center Enamel provides comprehensive support to ensure the success of your wastewater management project.

When it comes to wastewater storage tanks, Center Enamel offers the most reliable, durable, and high-performance solutions in the market. Manufactured in ISO 9001:2008 quality-controlled facilities, our tanks meet the most stringent industry standards, ensuring that your wastewater storage needs are met with the utmost reliability and safety.

Choose Center Enamel for all your wastewater storage requirements, and experience the difference that world-class quality and innovative technology can make.

Contact us today to learn more about our wastewater storage solutions or to request a customized quote for your next project.