-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (410)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (872)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

High Performance Epoxy-Coated Tanks For Anaerobic Digesters Maximizing Durability And Efficiency

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008 , AWWA D103 , OSHA , BSCI |

| Model Number: | J2016012306 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008 , AWWA D103 , OSHA , BSCI | Model Number | J2016012306 |

| Acid And Alkalinity Proof: | Standard Coating Suits For PH3 - PH11, Special Coating Suits For PH1 - PH14 | Usage: | Waste Water Treatment , Sewage Treatment , Effluent Treatment Ect. |

| Corrosion Resistance: | Excellent ! Suitable For Waste Water Salt Water, Sea Water, High Sulfur Crude Oil, Salt Fox, Organic And Inorganic Compounds | Spark Test: | >1500 V |

| Service Life: | Over 30 Years | Capactiy Available: | 20 M3 To 18,000 M3 |

| PH Range: | A Grade Sheet PH:3-11, AA Grade Sheet PH : 1-14 | Highlight: | Anaerobic Digesters Epoxy-Coated Tanks,High-Performance Epoxy-Coated Tanks |

Product Description

Anaerobic digesters play an essential role in the treatment of organic waste and the production of biogas. These systems are specifically designed for anaerobic digestion, a process that breaks down organic materials in the absence of oxygen, resulting in valuable byproducts like methane, a renewable energy source. Given the harsh and corrosive conditions within anaerobic digesters, selecting the right materials for their construction is crucial to ensure longevity and efficiency.

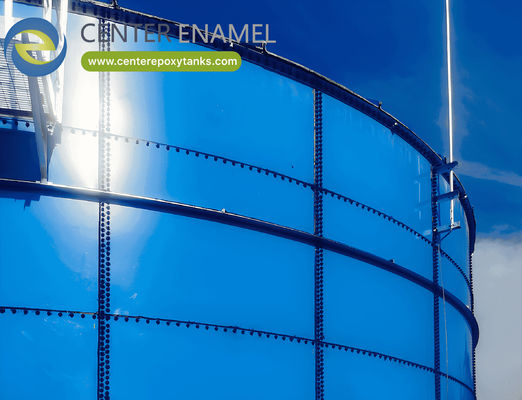

One of the most effective materials used in these systems is epoxy-coated tanks. These tanks are particularly advantageous in anaerobic digestion environments, offering high durability and resistance to corrosion. For industries utilizing anaerobic digesters, epoxy-coated tanks provide an optimal solution for improving operational efficiency and significantly reducing maintenance costs.

Why Epoxy Coated Tanks Are Ideal for Digesters ?

Corrosion Resistance

Digesters are often exposed to highly corrosive environments, including acidic gases and chemical waste. The internal conditions can cause rapid deterioration in materials that are not designed to withstand such stress. Center Enamel, with over 30 years of experience in tank development, has partnered with AkzoNobel to create an advanced fusion-bonded epoxy coating technology. This coating offers exceptional corrosion resistance and adhesion, enhanced by a specialized electrostatic spraying technique that ensures uniformity and durability.

Epoxy Coated Tanks Specifications:

Epoxy-coated tanks from Center Enamel meet the rigorous standards of AWWA D103-09 and ISO 9227 / ASTM B117. They are cost-effective, easy to install, and have quickly gained customer recognition for their superior quality and longevity, making them ideal for demanding digester environments.

Durability and Longevity

The durability of epoxy-coated tanks is another key factor that makes them ideal for use in digesters. These tanks are designed to withstand the physical and chemical stresses common in digestion processes, offering a long-lasting solution that minimizes the need for frequent replacements. This durability translates to lower long-term costs, as companies can rely on these tanks to perform efficiently over many years with minimal maintenance.

Chemical Compatibility

Digesters process a variety of chemical substances, many of which can be highly reactive with certain materials. Epoxy coatings are chemically inert, meaning they do not react with the substances stored within the tank. This compatibility ensures that the tanks maintain their structural integrity and do not contribute to contamination or degradation of the materials being processed.

Applications of Epoxy Coated Tanks in Digesters

Biogas Production

Epoxy-coated tanks are particularly valuable in the production of biogas, where the anaerobic digestion of organic materials generates methane-rich gas. The corrosive nature of biogas, particularly due to hydrogen sulfide and other impurities, requires tanks that can withstand these conditions. Epoxy-coated tanks provide the necessary protection, preventing the formation of rust and corrosion that could compromise the gas production process.

Wastewater Treatment

In wastewater treatment facilities, digesters play a critical role in breaking down sewage and other organic waste. Epoxy-coated tanks for wastewater treatment offer a safe and efficient solution that minimizes the risk of chemical reactions and corrosion. The tanks' resistance to the harsh chemicals found in wastewater ensures that they remain functional and reliable throughout the treatment process.

Sludge Storage

The storage of sludge, a byproduct of the digestion process, also benefits from the use of epoxy-coated tanks. Sludge can be highly corrosive, especially when it contains residual chemicals from the digestion process. Epoxy coatings protect the tank walls from the corrosive effects of sludge, preserving the tank's structural integrity and extending its lifespan.

Epoxy Coated Tanks vs. Other Materials

Epoxy Coating vs. Stainless Steel

When comparing epoxy-coated tanks to stainless steel tanks, the former offers a more cost-effective solution for many applications. While stainless steel is highly resistant to corrosion, it is significantly more expensive and may still suffer from pitting and crevice corrosion over time. Epoxy-coated tanks, on the other hand, provide comparable corrosion resistance at a lower cost, making them an attractive option for businesses looking to optimize their budgets without compromising on quality.

Epoxy Coating vs. Concrete Tanks

Concrete tanks are another alternative used in digesters, but they come with their own set of challenges. Concrete is prone to cracking and can be susceptible to chemical attack, especially in acidic environments. A comparison between epoxy-coated and concrete tanks shows that the former are less likely to suffer from such issues, offering better overall durability and protection. Additionally, the maintenance and repair costs associated with concrete tanks can be higher, further highlighting the advantages of epoxy coatings.

Cost-Benefit Analysis of Epoxy Coated Tanks

Epoxy-coated tanks present a compelling option for companies in the digester industry. The initial investment is lower than that of stainless steel tanks, and the long-term savings on maintenance and replacements further enhance their value. The extended lifespan and reduced risk of corrosion-related failures make epoxy-coated tanks a smart choice for businesses aiming to maximize efficiency and profitability.

Future Trends and Outlook

As environmental regulations become increasingly stringent and the demand for sustainable energy solutions grows, the role of epoxy-coated tanks in digesters is likely to expand. Advancements in coating technology and material science will likely enhance the performance and cost-effectiveness of these tanks, reinforcing their position as a preferred choice in the industry.

Epoxy-coated tanks provide a range of benefits that make them ideally suited for use in digesters. Their corrosion resistance, durability, and chemical compatibility ensure that they can withstand the harsh conditions typical of these environments. When compared to other materials, epoxy-coated tanks offer a cost-effective, long-lasting solution that can help companies in the digester industry optimize their operations.

Center Enamel is a leading provider of comprehensive organic waste treatment solutions, focused on urban ecological and environmental protection. Specializing in equipment manufacturing, process development, and engineering construction, Center Enamel delivers integrated solutions that support waste reduction, resource recovery, and the harmless treatment of municipal solid waste, improving ecological quality. In recent years, Center Enamel has aligned with international standards, earning multiple global certifications. Continuous innovation has led to the development of high-quality environmental equipment tailored to market needs, enhancing project quality and efficiency. Center Enamel's presence spans the United States, Russia, Australia, Panama, and more, reflecting a strong position in the global environmental sector.

Contact us today to learn more about how Center Enamel’s advanced epoxy-coated tanks can improve the efficiency and longevity of your digestion systems. Our team of experts is ready to provide tailored solutions that meet your specific needs, ensuring the highest standards of quality and performance.