-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

18000 m3 Wastewater Treatment Projects For Waste Resource Utilization And Environmental

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W20171016013 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 10-30 days after deposit received |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W20171016013 |

| Coating Thickness: | 0.25mm~0.40mm & Double Coating | Capacity: | 20 M3 To 18,000 M3 |

| Foundation: | Concrete Or Glass Fused Steel | Size Of Panel: | 2.4M * 1.2M |

| Easy To Clean: | Smooth, Glossy, Inert, Anti-adhesion | Feature: | Eco-friendly, Durability |

| High Light: | 18000 m3 Wastewater Treatment Projects,Wastewater Treatment Projects Environmental |

||

Product Description

Center Enamel Leads A New Era Of Biogas Engineering, A Win-Win Situation For Waste Resource Utilization And Environmental

As a leader in Asia's enamel assembled tank industry and a high-quality service provider for environmentally friendly EPC and anaerobic process sections, Genzon Technology has been committed to the innovation and development of the environmental protection industry, constantly exploring innovative solutions for water treatment, and leading high-quality development in the field of water treatment. Years of innovative development have allowed the company to master a number of leading technologies and rich experience in the field of water treatment, provide more professional and reliable solutions to global customers based on international standards, and win the trust and praise of customers.

As a representative enterprise in the water treatment industry with multiple patented technologies, Genzon Technology continues to conduct innovative research and development around sewage treatment technology and equipment. It has mastered a number of core technologies and processes in the field of industrial wastewater treatment, and has strong project technical service advantages. The company closely integrates sewage treatment with corporate production, adopts optimal process technology solutions, improves sewage treatment effects and operational benefits, and comprehensively solves sewage problems for customers in brewing, pharmaceutical and other industries.

Center Enamel has been rooted in the biomass energy industry for many years and has achieved fruitful research and development results in biomass energy utilization technology and intelligent equipment manufacturing. It has successfully built high-quality biogas projects for many customers at home and abroad, and has rich engineering design and construction experience. The company uses innovative processes to convert organic waste such as livestock and poultry manure into efficient, clean and convenient biomass energy - biogas, which is important for alleviating the shortage of conventional energy, promoting sustainable development of social economy and improving the ecological environment. significance.

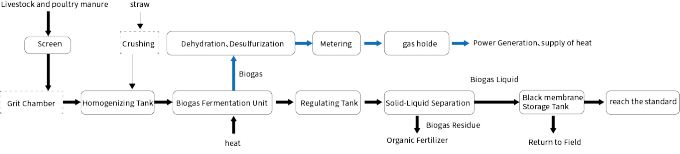

Biogas engineering process

Center Enamel takes the anaerobic digestion technology of fecal sewage from large-scale livestock and poultry farms as the main link, and provides customers with a system project integrating sewage treatment, biogas production, and resource utilization.

According to the type of process, it is divided into:

∎Energy ecological type: a treatment process in which sewage from livestock and poultry farms is used as water and fertilizer in farmland after anaerobic digestion.

∎ Energy-friendly and environmentally friendly: a treatment process in which the livestock and poultry sewage from livestock and poultry farms is treated and discharged to meet standards or has been reused for the final purpose.

Process flow and description

① Pretreatment: remove floating debris and sand from fermentation raw materials; uniform water quality and quantity, and adjust temperature.

② Biogas fermentation: Use microorganisms to decompose fermentation raw materials under anaerobic conditions to produce biogas; determine the appropriate fermentation process based on the characteristics of fermentation raw materials, fermentation time, feeding method, etc.

③ Biogas residue and biogas slurry treatment: The fermentation device discharges the material for solid-liquid separation; the biogas residue is made into organic fertilizer; the biogas slurry is stored and returned to the field.

④ Biogas purification, storage and utilization: The biogas produced by the fermentation device is dehydrated and desulfurized and stored in a gas storage tank, and then used for production and daily use.

Process technology advantages

① Use waste more thoroughly

It can carry out comprehensive harmless treatment and resource utilization of livestock and poultry manure, allowing various applicable wastes to enter the system for fermentation treatment, with high gas production rate and high overall profit.

②Multi-purpose biogas treatment

According to the different needs of customers, the biogas generated by the project can be processed for multiple purposes, such as power generation, heating, biogas purification, etc.

③More stable operation in the later period

Through process optimization and the use of self-developed complete sets of equipment, we ensure stable operation in the later stages of the project and make biogas utilization more valuable.

④ Double benefits in economic environment

For the treatment of biogas residue and biogas slurry, a complete treatment system is used to ensure that the treated biogas slurry meets the emission standards and achieves both economic and environmental benefits.

Center Enamel has long been focusing on comprehensive water environment management and has now formed a complete industrial chain including process research and development, core equipment manufacturing, engineering design, and construction. It can provide customers in different fields with technically stable, advanced technology and cost-effective sewage treatment projects. It has an excellent reputation and high market share in the industry. Relying on advanced sewage treatment technology and mature project management experience, Center Enamel has successfully completed projects in the fields of industrial wastewater, landfill leachate, aquaculture wastewater, municipal sewage, food waste and other fields for many customers, and has created multiple benchmark projects and won the Highly recognized by customers.