-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

OSHA alkalinity proof Wastewater Treatment Projects Landfill Leachate Treatment

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W20161227006 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W20161227006 |

| Applications: | Water , Waste Water, Digester , Reactor , Grain , Sludge , Chemicals | Acid And Alkalinity Proof: | PH1 - PH14 |

| Usage: | Waste Water Treatment , Sewage Treatment, Effluent Treatment, Ect. | Defect Free: | Minimum Maintenance Needed |

| Installation: | By Jacking Machine Or Steel Pole, Fast In Installation | High Light: | alkalinity proof Wastewater Treatment Projects,OSHA Wastewater Treatment Projects |

Product Description

Center Enamel’S Leading Technology Unlocks A New Realm Of Landfill Leachate Treatment

As a leader in Asia's enamel assembled tank industry and a high-quality service provider for environmentally friendly EPC and anaerobic process sections, Center Enamel has been committed to the innovation and development of the environmental protection industry, constantly exploring innovative solutions for water treatment, and leading high-quality development in the field of water treatment. Years of innovative development have allowed the company to master a number of leading technologies and rich experience in the field of water treatment, provide more professional and reliable solutions to global customers based on international standards, and win the trust and praise of customers.

As a representative enterprise in the water treatment industry with multiple patented technologies, Center Enamel continues to conduct innovative research and development around sewage treatment technology and equipment. It has mastered a number of core technologies and processes in the field of industrial wastewater treatment, and has strong project technical service advantages. The company closely integrates sewage treatment with corporate production, adopts optimal process technology solutions, improves sewage treatment effects and operational benefits, and comprehensively solves sewage problems for customers in brewing, pharmaceutical and other industries.

In response to various current problems in landfill leachate treatment, Center Enamel has launched the optimal solution to achieve reduction and harmless treatment of landfill leachate. This solution is based on the premise of stable and continuous discharge standards, comprehensive consideration of the water quality and quantity of landfill leachate, and the economy, rationality, and operability of the treatment process, and is determined after technical and economic comparisons. It can deeply remove organic pollutants that are difficult to degrade, improve the effluent standards of wastewater treatment, and prevent environmental pollution.

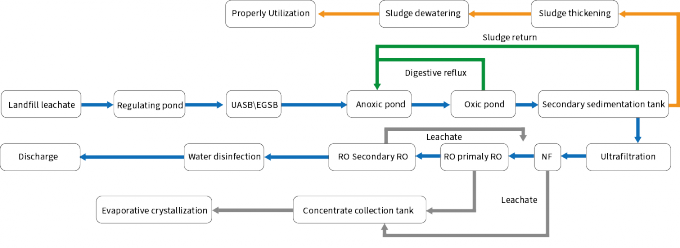

Landfill leachate treatment process

Based on the incoming water quality, water quantity and discharge requirements of landfill leachate, Center Enamel comprehensively selects mature and applicable processes. In many project cases, pretreatment + biochemical method + membrane separation method are mostly used. This process not only has low production cost, but also has good effluent quality and complies with the newly promulgated national first-level emission standards.

Process technology advantages

①The treatment effect is remarkable

The process is mature and applicable. It can not only remove organic matter, suspended solids, etc. in landfill leachate, but also effectively remove ammonia nitrogen and total nitrogen to ensure that the effluent meets discharge standards and is suitable for the advanced treatment of landfill leachate.

②Low operating cost

In the landfill leachate treatment project, Center Enamel uses the enamel assembled tanks independently developed and produced by the company as modular anaerobic treatment units to replace the structures of traditional sewage treatment stations, achieving modular design and construction and reducing the floor space of the sewage plant. Reduce operating costs.

Center Enamel has long been focusing on comprehensive water environment management, and has now formed a complete industrial chain including process research and development, core equipment manufacturing, engineering design and construction. It can provide customers in different fields with technically stable, advanced technology and cost-effective sewage treatment projects. It has excellent reputation and high market share in the industry. Relying on advanced sewage treatment technology and mature project management experience, Center Enamel has successfully completed projects in the fields of industrial wastewater, landfill leachate, aquaculture wastewater, municipal sewage, food waste and other fields for many customers, and has created multiple benchmark projects and won the Highly recognized by customers.