-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

Glass Fused Steel Biogas Plant Project For Landfill Leachate Project

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W |

| Tank Material: | Glass Fused To Steel | Foundation: | Concrete Or Glass Fused Steel |

| Steel Plates Thickness: | 3mm To 12mm , Depends On The Tank Structure | Size Of Panel: | 2.4M * 1.2M |

| Easy To Clean: | Smooth, Glossy, Inert, Anti-adhesion | Permeability: | Gas / Liquid Impermeable |

| High Light: | Glass Fused Steel Biogas Plant Project,Steel Biogas Plant Project For Landfill |

||

Product Description

Center Enamel leads innovation in landfill leachate treatment and creates a new model for landfill leachate Project

Shijiazhuang Zhengzhong Technology Co., Ltd. is a comprehensive high-tech enterprise whose main business is the R&D, manufacturing and sales of enamel assembled tanks, environmentally friendly diversified equipment, and the undertaking of environmentally friendly EPC projects and anaerobic process sections. The company's business covers food waste, landfill leachate, municipal sewage, biogas projects, aquaculture industry, industrial sewage, petrochemicals, metallurgy and other fields. It specializes in providing customers with comprehensive services such as engineering design, equipment R&D and manufacturing, installation and commissioning, and engineering construction.

Center Enamel is innovation-oriented and continues to lead the innovation of equipment technology. It empowers the intelligent manufacturing of diversified equipment with its innovative research and development technology of enamel assembly tanks, and develops a series of environmentally friendly and diversified equipment suitable for all walks of life. It also integrates years of technology accumulation and resource accumulation. The advantages extend to the field of environmentally friendly EPC engineering, building an entire industrial chain from enamel assembled tanks to diversified equipment, environmentally friendly engineering, and anaerobic process sections. Relying on advanced R&D technology and high-quality service system, the company has successfully ranked among the well-known enterprises in the environmental protection industry, becoming the leader in the enamel assembled tank industry in Asia, an intelligent manufacturer of diversified environmental protection equipment in China, and a high-quality service provider in environmental protection EPC and anaerobic process sections. .

Center Enamel undertook the landfill leachate project in Taizhou City, Zhejiang Province. Considering that the landfill leachate of this project has high metal content and strong acidity, Genzon Technology used AA-grade enamel to treat the steel plates of the enamel assembly tanks, and added anti- Cathodic protection measures against potential corrosion to ensure that the storage tank has excellent corrosion resistance, thus ensuring the safe and stable operation of the project.

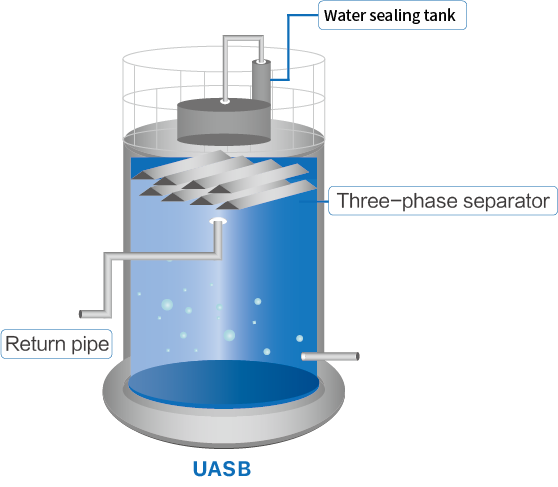

In view of the incoming water quality, water quantity and discharge requirements of landfill leachate, the company selected the pretreatment + biochemical method + membrane separation process after comprehensively considering many mature and applicable process solutions. This process not only has the advantage of low production cost, but also ensures that the effluent water quality meets the newly promulgated national first-level emission standards, providing a feasible and reliable solution for environmental protection projects.

The purpose of the pretreatment process is mainly to remove ammonia nitrogen or inorganic impurities, or to improve the biodegradability of leachate.

The main targets of biochemical treatment are organic pollutants, nitrogen, phosphorus, etc. in the leachate.

The main objects treated by membrane separation method are suspended solids, dissolved solids and colloids in the leachate, and the treatment method should be reasonably selected according to the treatment requirements.

When sludge is generated during the leachate treatment process, the sludge should be properly treated. The selection of treatment methods in each treatment process should be determined after comprehensive consideration of incoming water quality, water volume, treatment efficiency, discharge standards, technical reliability and economic rationality.

Years of in-depth research on sewage treatment technology and processes have allowed Center Enamel to optimize and innovate sewage treatment processes in different fields, maximize the advantages of sewage treatment processes, and thus solve sewage treatment problems for customers in a pragmatic manner. So far, Center Enamel has created a number of benchmark projects in the fields of industrial wastewater, aquaculture wastewater, food waste, landfill leachate, municipal sewage, etc., fully demonstrating its strong strength in engineering construction, equipment manufacturing, process research and development, etc. Gained recognition and trust from customers. In the future, Center Enamel will continue to delve into the sewage treatment industry and provide customers with high-quality sewage treatment processes and sewage treatment projects.