-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

3450N/cm 20m3 Biogas Plant Project In Food Waste Treatment Environmental Protection

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W201609013 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W201609013 |

| Coating Thickness: | 0.25mm~0.40mm & Double Coating | Adhesion: | 3,450N/cm |

| Service Life: | ≥30 Years | Holiday Test: | >1500v |

| Elastic: | Same As Steel Sheet ,around 500KN /mm | Capacity: | 20 M3 To 18,000 M3 |

| High Light: | 20m3 Biogas Plant Project,3450N/cm Biogas Plant Project |

||

Product Description

Center Enamel is innovation-oriented and continues to lead the innovation of equipment technology. It empowers the intelligent manufacturing of diversified equipment with its innovative research and development technology of enamel assembly tanks, and develops a series of environmentally friendly and diversified equipment suitable for all walks of life. It also integrates years of technology accumulation and resource accumulation. The advantages extend to the field of environmentally friendly EPC engineering, building an entire industrial chain from enamel assembled tanks to diversified equipment, environmentally friendly engineering, and anaerobic process sections. Relying on advanced R&D technology and high-quality service system, the company has successfully ranked among the well-known enterprises in the environmental protection industry, becoming the leader in the enamel assembled tank industry in Asia, an intelligent manufacturer of diversified environmental protection equipment in China, and a high-quality service provider in environmental protection EPC and anaerobic process sections. .

The Beijing kitchen waste treatment project built by Center Enamel mainly treats concentrated tank slurry and kitchen slurry, using the anaerobic fermentation biogas production system, biogas purification and power generation system, and sewage, biogas residue and odor treatment in the kitchen waste treatment system. system. This project has become the company's technical benchmark in the field of food waste treatment and a representative project with typical demonstration significance, and has played an important role in the company's promotion of food waste treatment technology across the country.

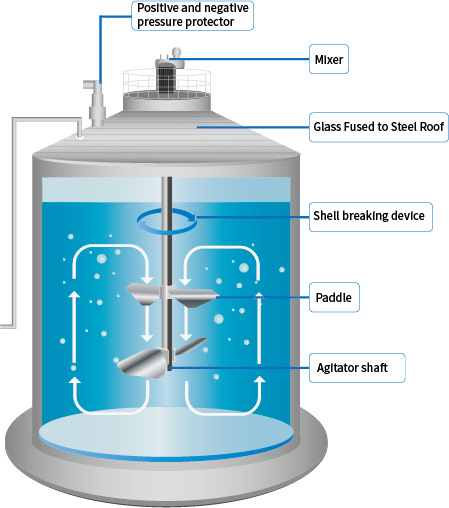

The Beijing food waste treatment project uses a CSTR reactor. The entire reactor uses an enamel assembly tank as the tank body. It has the advantages of short construction period, low cost, superior corrosion resistance, and easy installation. These features not only improve the construction efficiency and operational effects of the project, but also effectively reduce the overall cost.

Different from traditional CSTR reactors, Genzon Technology's CSTR reactor solves the problems of low mixing efficiency, low fermentation efficiency, and low gas production efficiency in the existing technology, ensuring highly stable and efficient operation inside the reactor and ensuring the safety of the project. running result.