-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Center Enamel Provides GFS Tank Design, Manufacturing, and Installation for Customers All Over the World

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, NSF - 61 , AWWA D103 , OSHA , BSCI |

| Model Number: | W20160831001 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 30 days after deposit received |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Center Enamel Provides GFS Tank Design, Manufacturing, and Installation for Customers All Over the World

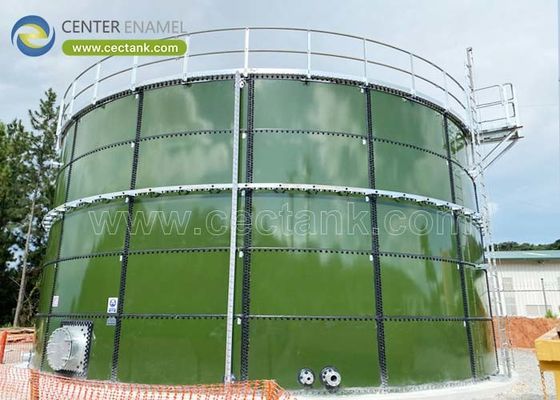

At Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), we specialize in the design, manufacturing, and installation of Glass-Fused-to-Steel (GFS) tanks, offering high-quality, reliable storage solutions for various applications worldwide. As the global leader in GFS tank technology, we have over 30 years of experience in providing customized solutions for industries such as water treatment, biogas production, wastewater management, fire protection, and industrial effluents. Our expertise extends to providing bolted storage tanks that are engineered to meet the highest industry standards, ensuring durability, safety, and efficiency in every project.

As a leading storage tank manufacturer worldwide. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks Welded Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Bio gas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

Comprehensive GFS Tank Solutions for Diverse Applications

Glass-Fused-to-Steel (GFS) tanks are the ideal choice for industries that require corrosion-resistant, durable, and long-lasting storage solutions. Whether for potable water, fire water, wastewater, or chemical storage, Center Enamel offers a wide range of GFS tank designs that cater to the unique needs of our clients across various sectors.

We work closely with our customers to provide fully customized tank solutions that align with project specifications, local regulations, and environmental considerations. Our comprehensive approach includes design, manufacturing, and installation, ensuring that each tank meets the highest performance and safety standards.

Designing the Perfect GFS Tank for Your Needs

Our design team at Center Enamel works with state-of-the-art software and engineering tools to ensure that each GFS tank design is optimized for functionality, efficiency, and safety. With a focus on modularity, ease of installation, and long-term reliability, our designs are tailored to the specific requirements of each project. We take into account factors such as:

Storage capacity: GFS tanks can be designed to accommodate a wide range of capacities, from small-scale tanks to large-scale industrial storage solutions.

Application type: Whether it’s potable water, industrial effluent, wastewater, or fire protection, we design tanks to meet the needs of specific applications, including biogas, sludge, and chemical storage.

Environmental considerations: We design tanks that are resilient to environmental factors such as extreme temperatures, corrosive chemicals, and seismic activity.

Safety standards: All of our designs adhere to international safety and quality standards, including AWWA D103-09, NSF/ANSI 61, ISO 9001, and other relevant certifications.

Our design process ensures that each tank not only meets the storage requirements but also provides long-lasting durability and minimal maintenance.

Manufacturing Glass-Fused-to-Steel Tanks with Precision and Excellence

As a leading GFS tank manufacturer, Center Enamel operates state-of-the-art production facilities equipped with the latest technologies. Our manufacturing process is designed to produce tanks that offer superior strength, corrosion resistance, and durability.

The Glass-Fused-to-Steel coating is applied to high-quality steel panels using advanced technology, creating a non-porous, smooth surface that is highly resistant to corrosion and chemical reactions. This fusion process ensures that the steel panels maintain their structural integrity over time, even in the most challenging environments.

The key benefits of our GFS tanks manufacturing process include:

Corrosion resistance: The fusion of glass and steel ensures a smooth, durable surface that resists rust, corrosion, and chemical reactions, making it perfect for wastewater, water, and industrial effluent storage.

Precision engineering: Every tank component is fabricated with precision, ensuring that the tanks meet exact specifications for performance and capacity.

Cost-effective production: Our manufacturing process is streamlined for efficiency, ensuring that we can deliver high-quality tanks at competitive prices.

Customization options: We offer customizable options, including tank height, diameter, and interior coatings, to meet the specific needs of each project.

Efficient and Expert Installation of GFS Tanks Worldwide

At Center Enamel, we understand the importance of on-time and professional tank installation. Our installation team is highly trained and experienced in the assembly of GFS tanks, ensuring that the installation process is seamless and efficient. Whether it’s a small-scale project or a large, complex installation, we are equipped to handle it with precision and professionalism.

Key aspects of our installation process include:

On-site assembly: GFS tanks are designed to be modular, meaning that they can be assembled on-site in a short amount of time. Our teams work efficiently to ensure that your tank is ready for operation without delay.

Global reach: With over 90 countries served worldwide, Center Enamel has the experience to install tanks in diverse geographic and environmental conditions, ensuring that every installation meets local regulations and standards.

Safety and compliance: Our installation team follows strict safety protocols to ensure the safe and successful installation of every GFS tank.

After-sales support: After the installation is complete, we offer comprehensive after-sales support, including maintenance and service to ensure the ongoing efficiency and performance of the tank.

Why Choose Center Enamel for GFS Tanks?

Global Leader in Tank Solutions: With over 30 years of experience, Center Enamel is a globally recognized leader in the design, manufacturing, and installation of Glass-Fused-to-Steel Tanks.

Customizable and Flexible: Our GFS tanks are fully customizable to meet the unique requirements of each customer, from storage capacity to application needs and environmental considerations.

High-Quality Manufacturing: We use the latest technology and the highest-quality materials in the production of our tanks, ensuring long-term durability and performance.

Global Reach: With completed projects in over 90 countries, we have the expertise to provide GFS tank solutions in diverse regions and industries.

Full-Service Solution: From design to installation and after-sales support, we offer a complete package to ensure the success of your project.

Sustainability and Safety: We prioritize sustainable and safe solutions, meeting or exceeding global industry standards and environmental regulations.

Applications of GFS Tanks

Center Enamel's Glass-Fused-to-Steel Tanks are suitable for a variety of industries, including:

Potable Water Storage: Safe storage solutions for drinking water that comply with NSF/ANSI 61 certification.

Wastewater Treatment: Corrosion-resistant tanks for storing treated or raw sewage and wastewater.

Biogas Production: Anaerobic digestion tanks for biogas plants.

Fire Protection: Fire water tanks designed to meet NFPA-22 standards.

Industrial Effluent Storage: Safe containment of chemical or industrial wastewater.

Global Impact and Reliability

With completed projects spanning continents—from Asia and Europe to Africa and the Americas—Center Enamel has built a strong reputation for providing reliable, high-quality GFS tanks that meet the unique needs of every client. We understand the local challenges, regulations, and requirements, and are proud to be the trusted partner for customers around the globe.

Whether you’re looking for a solution for water storage, wastewater treatment, fire protection, or biogas production, Center Enamel has the expertise, experience, and innovation to deliver the perfect GFS tank solution tailored to your needs.

Contact Us for Your GFS Tank Project

At Center Enamel, we are committed to providing the best GFS tank design, manufacturing, and installation services to customers worldwide. If you're interested in our Glass-Fused-to-Steel tank solutions, contact us today to discuss your project, and let us help you find the perfect storage solution for your needs.