-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

20 m³ Capacity Bolted Steel Tanks For Municipal And Industrial Drinking Water Storage

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | $5000~$20000 one set |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Bolted Liquid Storage Tanks for Municipal and Industrial Potable or Drinking Water Storage

What is Glass Fused to Steel Tanks?

Glass-Fused-to-Steel (Glass-Lined-Steel) is a unique tank finish. Two materials are fused together to achieve the best properties of both – the strength and flexibility of steel combined with the corrosion resistance of glass. Applied to both interior and exterior surfaces, Glass-Fused-to-Steel is able to provide many years of trouble free service in harsh environments.

Specification:

| Category | Specification |

|---|---|

| Coating Color | Dark green, or Customizing colors |

| Coating Thickness | 0.25~0.40mm, double coating |

| Acid and alkalinity proof | Acid and alkalinity proof |

| Adhesion | 3,450N/cm |

| Elastic | Same as steel sheet, around 500kN/mm |

| Hardness | 6.0 Mohs |

| Service life | ≥30 Years |

| Holiday test | >1500V |

| Permeability | Gas and liquid impermeable |

GFS Tank Advantages :

Safe

Durable.

Low-maintenance.

Cost-effective.

Code-compliant.

Convenient to specify and install

Free from corrosion and oxidation

Very light

Easily transportable

Can be installed anywhere in the world

Minimal assembly time

Easily dismantled and re-used

Minimum maintenance

Easily installed accessories

Tank Roof Optional:

-Glass Fused to Steel Tank Roof

-Double Membrane Roof / Single Membrane Roof

-Aluminum Deck Roof

-Aluminum Dome Roof

-FRP / GRP Roof

Design criterion & certificates:

Supported by International Standards which cover the design and finish requirements:

OSHA, EN28765, NSF/ANSI 61, ISO9001, FDA, AWWA-D103-09

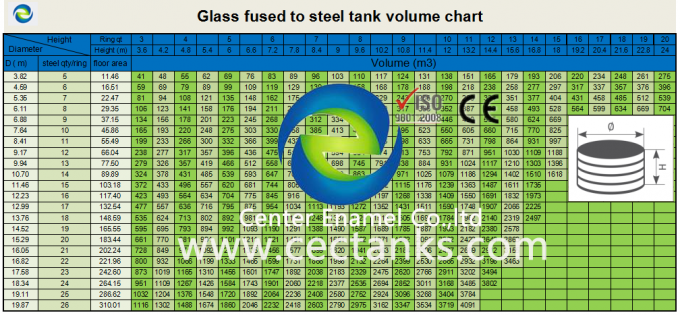

Tank Size Chart:

CEC full range of Tanks are available in the sizes listed in the table below:

Application Fields including:

· Municipal: In the municipal environment these tanks are used for drinking water, municipal waste leachate storage, sewage treatment, wastewater treatment and anaerobic digestion

· Industrial: Industrial applications catered for include industrial effluent storage and process, industrial effluent digestion, process water storage and bulk solids storage

· Agricultural: For agriculture, Glass-Fused-to-Steel Tanks & Silos are utilised for slurry storage, farm biogas production and grain and forage silos

· Mining: The tough chemical and abrasion resistance of PERMASTORE® Glass-Fused-to-Steel Tanks & Silos make them ideal for storage and process applications

· Biofuels: As well as biogas applications, these tanks can be used within the biofuels market for vegetable oils, bio-diesel and ethanol storage

Who we are?

Center Enamel Co., Ltd has been manufacturing and installing a complete line of bolted steel tanks and enamel storage tanks for the potable water, wastewater, fire protection, rain harvesting and bio energy digester Industries since 1989.

CEC Advantages:

- R&D Ability

With nearly 30 years experience in enameling industry, Center Enamel Co.,Ltd has become the largest and most professional enamel tank manufacturer in China.

We already established a professional R&D team and advanced laboratory. With this strong enameling R&D ability, we can meet various demands of customers.

- Advanced Production Line - CNC & Automatic production machine

- Quality Control

- Raw Material Test.

- Enamel Sample Test

- Destructive Test

- Acid and Alkali Resistance Test

- 1500V Holiday Test

- Adherence Test

- Enamel Thickness Test