-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

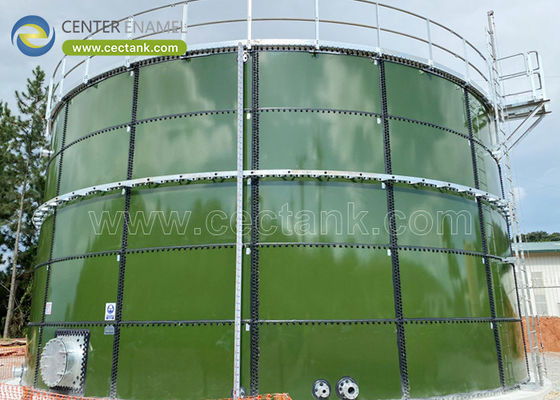

Short Construction Period Bolted Steel Tanks As Wastewater Tanks

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W |

| Tank Body Color: | Dark Green / Can Be Customized | Corrosion Integrity: | Excellent |

| Steel Plates Thickness: | 3mm To 12mm , Depends On The Tank Structure | Chemical Resistance: | Excellent |

| Size Of Panel: | 2.4M * 1.2M | Easy To Clean: | Smooth, Glossy, Inert, Anti-adhesion |

| High Light: | Short Construction Period Bolted Steel Tanks,Wastewater Bolted Steel Tanks |

||

Product Description

Short Construction Period Bolted Steel Tanks as Wastewater Tanks

In the realm of wastewater management, time is of the essence. To meet the increasing demand for efficient and reliable solutions, bolted steel tanks with short construction periods have emerged as a game-changer. In this article, we delve into the benefits and applications of these innovative tanks in wastewater treatment.

The Need for Rapid Solutions in Wastewater Management

With urbanization and industrialization on the rise, the volume of wastewater generated continues to escalate. Municipalities, industries, and communities are under immense pressure to implement effective wastewater treatment systems quickly. This is where short construction period bolted steel tanks shine, offering a host of advantages:

Rapid Deployment: Unlike traditional concrete tanks that require lengthy construction periods, bolted steel tanks can be assembled on-site swiftly. This rapid deployment minimizes downtime and allows for faster commissioning of wastewater treatment facilities.

Cost-Effective: The quick assembly of bolted steel tanks translates into cost savings. Reduced labor hours, lower construction time, and efficient logistics contribute to a more budget-friendly solution for wastewater management projects.

Flexibility and Scalability: Bolted steel tanks offer unparalleled flexibility and scalability. They can be customized to accommodate varying wastewater volumes and treatment processes, making them ideal for both small-scale and large-scale applications.

Durability and Reliability: Constructed from high-quality steel panels and utilizing advanced sealing techniques, these tanks boast exceptional durability and reliability. They can withstand harsh environmental conditions, corrosive elements, and heavy loads, ensuring long-term performance and minimal maintenance requirements.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Biogas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

Bolted steel tanks have emerged as a game-changing solution for constructing biogas digester tanks due to their numerous advantages over traditional materials and construction methods. These tanks are typically made of corrosion-resistant steel panels that are assembled on-site using bolts and gaskets, eliminating the need for extensive welding and concrete work. The modular nature of bolted steel tanks allows for easy customization in terms of size and shape to accommodate varying project requirements.

Advantages of Bolted Steel Tanks for Biogas Digesters

Rapid Construction: Bolted steel tanks can be assembled quickly, significantly reducing construction time compared to concrete or welded steel tanks. This rapid deployment is particularly advantageous for biogas projects aiming for swift implementation and commissioning.

Cost-Effectiveness: The simplified construction process of bolted steel tanks translates to lower labor costs and fewer logistical expenses. Moreover, the durable nature of steel ensures long-term reliability, reducing maintenance and replacement costs over the tank's lifespan.

Versatility: Bolted steel tanks offer versatility in terms of size, shape, and configuration, allowing for customization according to specific project requirements. This flexibility enables biogas plant designers to optimize tank design for efficient biogas production and storage.

Durability and Corrosion Resistance: Steel is inherently robust and resistant to corrosion, ensuring the longevity and structural integrity of biogas digester tanks even in harsh environments. Additionally, modern coating technologies further enhance corrosion resistance, prolonging the tank's service life.

Ease of Maintenance: Bolted steel tanks are designed for easy maintenance and repair, with individual panels being replaceable without the need for extensive dismantling. This feature minimizes downtime and ensures continuous operation of biogas plants.

Center Enamel combines the excellent performance of various tanks to provide customers with solutions composed of diverse equipment combinations. This approach allows us to flexibly meet the needs and requirements of different application fields. Throughout the project construction process, the teams at Center Enamel collaborate closely, actively coordinate, and prioritize each step, conducting rigorous checks at every level to ensure the smooth completion of projects.

From being a leader in the Global GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.