-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

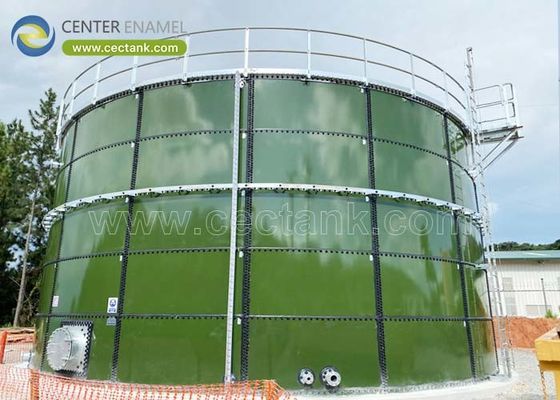

0.25mm Thickness Glass Fused Steel Tanks In Wastewater Treatment Projects

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W20160705006 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W20160705006 |

| Coating Thickness: | 0.25mm~0.40mm , Two Layer Of Coating Internal And External | Tank Material: | Glass Fused To Steel |

| Steel Grade: | ART 310 | Roof Available: | Glass Fused Steel Roof , Membrane Roof, Aluminum Roof , GRP Roof |

| High Light: | 0.25mm Thickness Glass Fused Steel Tanks,Glass Fused Steel Tanks Wastewater Treatment |

||

Product Description

The Advantages Of Glass-Fused-To-Steel Tanks And Quality Assurance In Wastewater Treatment Projects

With the continuous advancement of industrialization, wastewater generated from industrial activities has become a serious environmental issue. Industrial wastewater contains various harmful substances, and its direct discharge can potentially have severe impacts on water bodies, soil, and ecosystems. Therefore, finding efficient and feasible methods for industrial wastewater treatment becomes crucial. The discharge of industrial wastewater poses a potential threat to the environment and human health. Toxic components such as heavy metals and organic compounds contained in industrial wastewater may lead to water pollution, causing damage to aquatic life and ecosystems. To maintain environmental sustainability and human quality of life, efficient treatment of industrial wastewater is of utmost importance.

Industrial wastewater treatment involves physical, chemical, and biological processes aimed at removing harmful substances from wastewater and improving water quality. Common stages of industrial wastewater treatment include pretreatment, primary treatment, secondary treatment, and others, utilizing various equipment and technologies.

Introduction to Glass-Fused-to-Steel Tanks

Glass-fused-to-steel tanks are assembled on-site from specialized enameled steel plates, reinforcement bars, self-locking bolts, sealing glue, and other components. The raw material for steel plates uses enameled hot-rolled plates developed in collaboration with top domestic iron and steel enterprises, incorporating titanium alloy. The rapid and low-consumption on-site assembly technology shapes the tanks. After the enameled steel plates undergo high-temperature enameling at 820°-930°, the enamel glaze fuses with the steel plate surface, forming a solid inorganic coating with excellent corrosion resistance due to its chemical inertness. The enameling process represents an advanced coating and corrosion prevention technology in the current steel tank market.

Glass-Fused-to-Steel Tank Parameters

| Category | Specification |

| Coating Color | Black blue, Grey olive, Forest green, Cobalt blue, Desert tan etc. |

| Coating thickness | 0.25-0.45mm |

| Acid and alkalinity proof | Standard PH: 3~11, Special PH:1~14 |

| Adhesion | 3450N/cm² |

| Hardness | 6.0 (Mohs) |

| Service life | ≥30 Years |

| Holiday test | >1500V |

| Permeability | Gas liquid impermeable |

| Easy to clean | Smooth, glossy, inert, anti-adhesion |

| Corrosion resistance | Excellent, suitable for harsh environment |

Glass-Fused-to-Steel Tank Advantages

Superior Corrosion Protection Technology

Center Enamel has independently developed double-sided double-layer enameling technology, filling the gap in the field of hot-rolled double-sided enameling technology in the Chinese enamel industry. This technology is currently the best coating and corrosion prevention technology in the steel tank market, providing superior corrosion resistance.

Wide Application Range

Center Enamel has independently developed over 200 enamel formulations and patents, allowing for customized enamel formulation development based on customer requirements for the storage medium of Glass-Fused-to-Steel tanks. This customization ensures the tanks are widely applicable across different industries.

Site-Specific Design

Tailored to the construction site, Glass-Fused-to-Steel tanks are designed with features such as wind resistance and earthquake resistance, ensuring the tanks remain undamaged by natural factors such as earthquakes and typhoons.

Environmentally Friendly Utilization

Glass-Fused-to-Steel tanks can be flexibly designed in terms of tank size and color customization based on customer and environmental requirements. This design approach saves land space and aligns with the requirements of modern construction.

High Standardization Level

Glass-Fused-to-Steel tank steel plates and main components are standardized through automated production in the factory. After packaging, they are transported to the project site for standardized assembly. From production to installation, strict adherence to the design ensures the standardized manufacturing of tanks.

Simple and Fast Installation

Glass-Fused-to-Steel tanks are installed on-site through assembly, making the installation process simple, fast, less affected by weather conditions, and with a short and controllable installation period. After completion, tanks can be dismantled and reinstalled, facilitating relocation and expansion.

Product Quality Certification

As a leading manufacturer of Glass-Fused-to-Steel tanks in China, our quality system ensures compliance with EN ISO 28765:2016 and AWWA D103-19 requirements, certified through international standards such as ISO 9001, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001, and others.

Product Quality Testing

Center Enamel has a comprehensive quality testing standard for enameled steel plates throughout the process, ensuring that the produced enamel steel plates meet high-quality standards for different environments and usage conditions.

Raw Material Sampling Test: Batch testing of raw materials is conducted to ensure that all raw materials undergo quality inspection.

1500V Spark Test: Double-sided 1500V spark testing is performed on the produced plates to ensure they are delivered in the best quality condition.

Impact Test: Hydraulic press impact tests are conducted to test the fusion performance of enameled panels, ensuring longer lifespan and higher mechanical stress resistance.

Fish Scale Test: Standard enameled steel plates are baked at high temperatures, and if no fish scale issues occur after one hour at 400°C, the production quality is deemed qualified.

Consistency of Tank Color: Color difference testing is performed on plates from different batches and thicknesses to ensure consistent coloration.

Coating Thickness Test: Coating thickness is measured using a coating thickness gauge to ensure the enamel coating of Center Enamel's enameled steel plates falls within the standard range.

Acid-Alkali Resistance Test: Diluted solutions of citric acid or sodium carbonate are used to test acid-alkali resistance, evaluating the chemical corrosion resistance of enameled plates.

As a pioneer in the Asian Glass-Fused-to-Steel tank industry and a high-quality service provider in environmental protection EPC and anaerobic process segments, Center Enamel has been committed to innovation and development in the environmental protection industry. The company continuously explores innovative water treatment solutions, leading high-quality development in the field of water treatment. Years of innovation and development have enabled the company to master leading technologies and gain rich experience in the water treatment field, providing more professional and reliable solutions to global customers in line with international standards. This has earned the trust and praise of customers.

From south to north, from east to west, from domestic to international, Center Enamel's projects now cover 90 countries worldwide. Center Enamel will continue to leverage its core advantages in technology, equipment, and services to provide customers with more advanced and reliable water treatment solutions. The company will strengthen cooperation with domestic and foreign partners, continuously promote innovation and application of water treatment technology, and contribute to the global advancement of water treatment.