-

Glass Fused To Steel Tanks (463)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

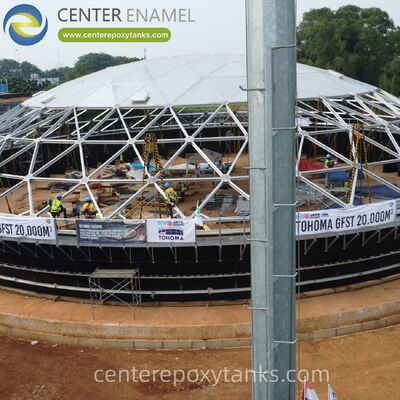

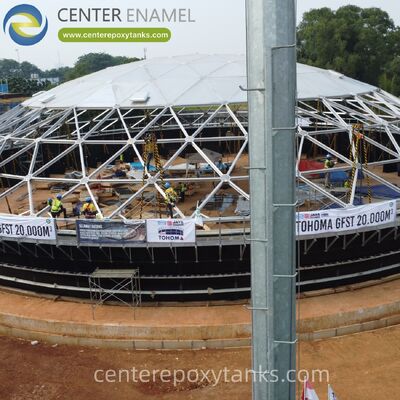

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (210)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Aluminum Dome Roof for Welded Stainless Steel Petrochemical Product Storage Tanks: Offers Superior Corrosion Resistance Against Aggressive Chemical Vapors and Industrial Environments

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

Aluminum Dome Roof for Welded Stainless Steel Petrochemical Product Storage Tanks: Offers Superior Corrosion Resistance Against Aggressive Chemical Vapors and Industrial Environments

In the petrochemical industry, the storage of intermediate and finished products—such as solvents, aromatics, and organic acids—requires infrastructure that can survive constant exposure to highly reactive substances. The integrity of the storage vessel is not only a matter of operational efficiency but a critical component of environmental and personnel safety. Aluminum Dome Roofs for Welded Stainless Steel Petrochemical Product Storage Tanks represent the gold standard for containment in these volatile settings. This system offers superior corrosion resistance against aggressive chemical vapors and industrial environments, providing a robust, clear-span cover that isolates hazardous materials. By combining the legendary chemical resilience of a welded stainless steel shell with the inert properties of an aluminum dome, operators can ensure long-term structural safety in the most demanding refinery conditions.

Unmatched Resistance to Chemical Attack and Acidic Condensation

Petrochemical storage environments are notoriously aggressive. Vapors from stored chemicals often condense on the underside of tank roofs, creating highly corrosive liquid films. In traditional carbon steel roofs, this "acidic rain" leads to rapid thinning, pitting, and eventual structural failure. Even with expensive internal coatings, the constant thermal expansion and chemical stress often cause the paint to crack and peel. The Aluminum Dome Roof offers a maintenance-free alternative.

Aluminum alloys naturally form a stable, protective oxide layer that is highly resistant to a wide range of petrochemical vapors, including sulfur compounds and various organic acids. This inherent resistance is the primary reason why the aluminum dome is the ideal choice for harsh industrial environments. Unlike steel, which requires constant monitoring and repainting, the aluminum dome remains structurally sound without the need for protective coatings. This is especially critical when paired with a welded stainless steel tank shell. Stainless steel provides the same high level of resistance for the primary liquid container, ensuring that neither the shell nor the roof introduces rust or scale into the high-purity petrochemical products.

Advanced Vapor Containment through Clear-Span Engineering

Managing fugitive emissions is a top priority in petrochemical facilities to meet strict air quality regulations and prevent the loss of high-value products. Many petrochemicals are highly volatile and hazardous if released. The Aluminum Dome Roof enhances vapor control through its unique clear-span architecture. Traditional roofs require internal support columns that penetrate the internal floating roof, creating dozens of leak paths for hazardous gases to escape into the headspace.

Because the geodesic dome is self-supporting, it requires no internal pillars. This allows the internal floating roof to maintain a 100% effective seal against the welded stainless steel shell. The dome then acts as a high-performance secondary containment shield, trapping any escaping vapors within the headspace. The precision-engineered batten-sealing system of the dome ensures that the tank remains weather-tight and gas-tight. By eliminating column penetrations and providing a sealed headspace, the system significantly reduces the volume of volatile organic compounds released, protecting both the facility's inventory and the health of the surrounding community.

Structural Stability and Thermal Regulation

In the petrochemical sector, structural safety is paramount. The Aluminum Dome Roof is a lightweight yet high-strength structure capable of withstanding extreme environmental loads, including high-speed winds and seismic activity. The triangular lattice design distributes stress evenly across the perimeter of the welded stainless steel shell. Because it weighs only one-third as much as a steel equivalent, the dome reduces the mechanical load on the tank foundation, allowing for safer long-term operation.

Thermal regulation is another essential benefit. Many petrochemicals are sensitive to temperature changes, which can cause them to degrade or increase in vapor pressure. Aluminum is highly reflective, bouncing back solar radiation and keeping the tank interior cool. This "cool roof" effect minimizes the thermal expansion of the stored liquids and reduces "breathing" losses. The clear-span nature of the dome also facilitates safer and more thorough inspections. Without a forest of internal columns to navigate, technicians can easily verify the integrity of the tank walls and seals. This combination of structural strength, thermal control, and ease of maintenance makes the aluminum dome and stainless steel tank the premier choice for modern petrochemical terminals.

Application Areas

The need for high-integrity chemical resistance and absolute structural resilience makes these domes essential for:

Aromatic Hydrocarbon Storage: Handling products like benzene and toluene that require strict vapor control.

Corrosive Intermediate Storage: Where the combination of a stainless steel shell and an Aluminum Dome Roof provides the best protection against chemical attack.

Fertilizer and Ammonia Terminals: Where aggressive atmospheric conditions require non-corrosive roofing solutions.

Coastal Petrochemical Hubs: Where the dome resists salt-air corrosion while protecting high-value chemical inventories.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment. Our approach to Aluminum Dome Roofs for Welded Stainless Steel Petrochemical Product Storage Tanks is defined by a commitment to technical precision and chemical safety:

Chemical-Resistant Engineering: We design geodesic dome systems specifically to withstand the unique chemical signatures and vapor pressures of various petrochemical products.

Advanced Manufacturing Standards: Our facility utilizes high-grade aluminum alloys and precision-welded stainless steel to ensure the entire tank structure is a seamless, corrosion-proof barrier.

Global Technical Support: We provide expert technical supervision for the assembly of clear-span domes and tank shells worldwide, ensuring absolute reliability for hazardous material storage.

Conclusion

In the demanding petrochemical industry, the quality of storage infrastructure is the first line of defense against environmental pollution and structural failure. Aluminum Dome Roofs for Welded Stainless Steel Petrochemical Product Storage Tanks provide the most effective barrier against chemical corrosion and vapor loss. By prioritizing a design that offers superior resistance to aggressive vapors, operators protect their assets and ensure the continuous, safe operation of their facilities. When these tanks are reinforced with the maintenance-free protection of an aluminum dome, they represent a world-class solution that balances safety, durability, and operational excellence.