-

Glass Fused To Steel Tanks (463)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

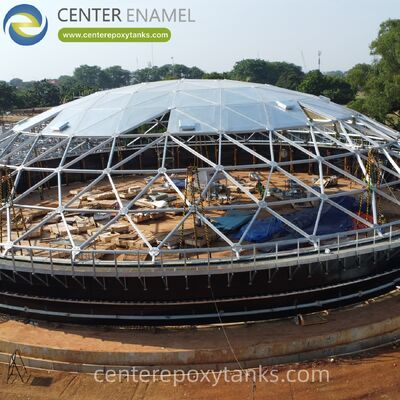

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (210)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

|

Detail Information |

|||

Product Description

Aluminum Dome Roof for Welded Stainless Steel Diesel Storage Tanks: Minimizes Fuel Evaporation and Prevents Rainwater from Compromising Fuel Stability

In the global energy and logistics sectors, diesel fuel is a foundational resource that requires specialized storage to maintain its combustion efficiency and chemical stability. Diesel is susceptible to degradation from moisture ingress, which can lead to microbial growth, and from thermal fluctuations, which increase evaporative losses. Aluminum Dome Roofs for Welded Stainless Steel Diesel Storage Tanks provide a comprehensive solution to these challenges. This system minimizes fuel evaporation and prevents rainwater from compromising fuel stability by utilizing a precision-engineered, clear-span geodesic structure. By combining the rust-proof durability of a welded stainless steel shell with the environmental shielding of an aluminum dome, operators can ensure their diesel reserves remain in peak condition for immediate use or long-term strategic storage.

Preserving Fuel Stability by Eliminating Rainwater Ingress

The single greatest threat to stored diesel is the presence of water. Even small amounts of rainwater entering a tank can lead to the formation of "diesel bug"—microbial colonies that thrive at the fuel-water interface. These microbes produce acidic byproducts that corrode fuel systems and create a thick sludge that clogs filters and damages engine injectors. Traditional steel roofs, which often rely on internal support pillars, are prone to leaking at penetration points and along welded seams as they age and rust.

The Aluminum Dome Roof addresses this vulnerability through its self-supporting design. As a clear-span structure, it requires no internal columns, meaning the roof surface is a continuous, penetration-free shield. The dome’s advanced batten-sealing technology provides a hermetic barrier that effectively prevents rainwater from compromising fuel stability. By keeping the interior of the welded stainless steel tank completely dry, the system prevents the accumulation of water in the tank bottom, ensuring that the diesel remains "clear and bright" and ready for high-performance machinery.

Minimizing Fuel Evaporation through Thermal Regulation

While diesel is less volatile than gasoline, it still suffers from evaporative losses, particularly in regions with high solar radiation. When a tank is exposed to direct sunlight, the internal temperature rises, increasing the vapor pressure and causing the tank to "breathe" out fuel vapors. This results in significant product shrinkage over time and contributes to volatile organic compound emissions.

The Aluminum Dome Roof acts as a high-performance thermal regulator. Aluminum is naturally highly reflective, bouncing back a significant portion of solar radiation and keeping the tank headspace cool. This "cool roof" effect minimizes fuel evaporation by maintaining a stable internal temperature. Furthermore, the clear-span nature of the dome allows for the unhindered operation of internal floating roofs. Without support columns to navigate, the floating roof can maintain a perfect seal against the smooth welded stainless steel wall, providing a double layer of protection against vapor loss. This synergy ensures maximum product retention and helps facilities comply with increasingly strict environmental air quality standards.

Material Longevity and Maintenance-Free Efficiency

The combination of welded stainless steel and an aluminum dome provides a storage solution with exceptional durability. Standard carbon steel tanks are prone to internal corrosion at the fuel-air interface, where moisture condenses on the walls. Welded stainless steel is immune to this type of localized attack, providing a robust and clean primary container. The Aluminum Dome Roof complements this by being virtually maintenance-free. It does not rust, scale, or require periodic sandblasting and repainting, even in harsh coastal or industrial environments.

The lightweight nature of the aluminum dome—roughly one-third the weight of a steel equivalent—also reduces the mechanical stress on the welded stainless steel shell and foundation. This weight reduction facilitates faster installation and improves the seismic resilience of the entire structure. The structural simplicity of the dome also enables safer and more effective inspections. Without internal columns to obstruct the view, technicians or automated sensors can easily verify the condition of the tank walls and the quality of the fuel. This reliability ensures maximum operational uptime and a significantly lower total cost of ownership over the life of the facility.

Application Areas

The need for absolute fuel stability and structural resilience makes these domes essential for:

Emergency Power Generation Centers: Ensuring that backup diesel supplies for hospitals and data centers remain uncontaminated.

Bulk Fuel Distribution Terminals: Managing large volumes of diesel for transportation and logistics networks.

Mining and Industrial Sites: Protecting fuel supplies from extreme dust and heavy rainfall in remote areas.

Marine Bunkering Facilities: Where the combination of a stainless steel shell and an Aluminum Dome Roof provides the best protection against salt-air corrosion.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment. Our approach to Aluminum Dome Roofs for Welded Stainless Steel Diesel Storage Tanks is defined by a commitment to technical precision and fuel integrity:

Stability-Focused Engineering: We design geodesic dome systems specifically to maximize environmental isolation and prevent fuel degradation.

Advanced Manufacturing Standards: Our facility utilizes high-grade aluminum alloys and precision-welded stainless steel to ensure the entire tank structure is a seamless, corrosion-resistant barrier.

Global Technical Support: We provide expert technical supervision for the assembly of clear-span domes and tank shells worldwide, ensuring absolute reliability for mission-critical diesel storage.

Conclusion

In the demanding world of energy management, the quality of storage infrastructure is the first line of defense against fuel loss and equipment failure. Aluminum Dome Roofs for Welded Stainless Steel Diesel Storage Tanks provide the most effective barrier against moisture ingress and thermal degradation. By prioritizing a design that minimizes evaporation and prevents rainwater contamination, operators protect their expensive fuel inventories and the machinery that relies on them. When these tanks are reinforced with the maintenance-free protection of an aluminum dome, they represent a world-class solution that balances safety, durability, and operational excellence.