-

Glass Fused To Steel Tanks (463)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (210)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

|

Detail Information |

|||

Product Description

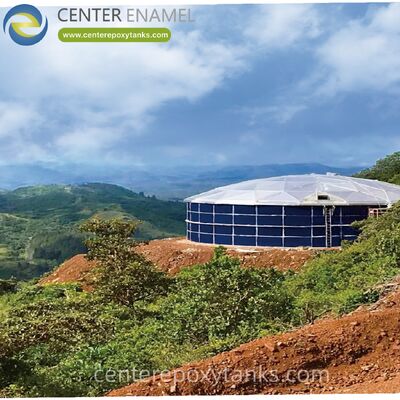

Aluminum Geodesic Dome Roof for Welded Stainless Steel Used Motor Oil Storage Tanks: Effectively Contains Noxious Odors and Volatile Organic Compounds for a Cleaner Environment

The collection and storage of used motor oil represent a significant environmental responsibility for automotive service centers, industrial plants, and recycling facilities. Used motor oil is a complex cocktail of degraded lubricants, heavy metals, and various combustion byproducts that often emit strong, unpleasant smells. Aluminum Geodesic Dome Roofs for Welded Stainless Steel Used Motor Oil Storage Tanks provide a high-performance containment solution. This system effectively contains noxious odors and volatile organic compounds for a cleaner environment by utilizing a gas-tight geodesic structure that encloses the tank headspace. By combining the superior chemical resistance of a stainless steel shell with the clear-span advantages of an aluminum dome, operators can manage hazardous waste streams while minimizing the facility's impact on air quality and the surrounding community.

Advanced Odor Containment and Air Quality Control

One of the most persistent challenges in used oil management is the mitigation of fugitive emissions. As the oil sits in the tank, it releases volatile organic compounds that can cause respiratory irritation and contribute to smog formation. Traditional open-top tanks or standard steel roofs with poor sealing allow these gases to escape freely into the atmosphere. The Aluminum Geodesic Dome Roof addresses this through a precision-engineered, enclosed design.

Unlike traditional roofs that require internal support columns, the geodesic dome is a self-supporting space-frame. This is a decisive advantage for odor control; internal columns in conventional tanks create penetration points and gaps in the roof structure where noxious gases can leak. By utilizing a column-free Aluminum Geodesic Dome Roof, the tank becomes a hermetically sealed unit. The dome’s advanced batten-sealing technology ensures that odors and volatile organic compounds are trapped within the headspace, where they can be effectively routed to carbon filtration or vapor recovery systems. This isolation is the core mechanism that effectively contains noxious odors, ensuring that the facility maintains a clean and professional environment.

Material Durability in Aggressive Waste Environments

Used motor oil can be surprisingly corrosive. It often contains organic acids and moisture that can lead to rapid pitting and structural thinning in standard carbon steel tanks. Welded stainless steel is the premier choice for the tank shell because it provides a non-reactive and robust primary container that resists chemical attacks. The Aluminum Geodesic Dome Roof complements this durability by offering a cover that is equally resistant to the corrosive vapors found in the tank headspace.

The aluminum alloys used in the dome naturally form a stable oxide layer that protects the metal from the sulfur-rich and humid atmosphere common in waste oil storage. Unlike traditional steel roofs, the aluminum dome does not require periodic sandblasting or repainting, which is a major safety advantage. In a used oil environment, any maintenance that involves sparking or abrasive dust is a fire risk; by choosing a maintenance-free aluminum dome, operators eliminate these hazards. Furthermore, the dome prevents rainwater from entering the tank. Water contamination can cause waste oil to emulsify, making it much more difficult and expensive to recycle. By providing a permanent, weather-proof shield, the dome ensures that the used oil remains dry and suitable for high-value re-refining processes.

Structural Efficiency and Inspection Safety

The structural simplicity of the geodesic design also improves the overall safety and efficiency of the facility. The clear-span nature of the Aluminum Geodesic Dome Roof makes it significantly safer for personnel to perform mandatory inspections. Without a forest of internal support pillars to navigate, technicians or automated monitoring sensors can easily verify the liquid levels and the integrity of the tank walls. This reduces the risk of undetected leaks and ensures that the secondary containment systems are never overloaded.

The lightweight nature of the aluminum dome—which is roughly one-third the weight of a steel equivalent—also improves the seismic resilience of the welded stainless steel tank. By reducing the top-heavy load, the dome ensures that the tank remains structurally stable during earthquakes or high-wind events, preventing the accidental release of hazardous waste. This comprehensive approach to structural and environmental safety makes the aluminum dome and stainless steel tank combination the gold standard for responsible waste oil management.

Application Areas

The need for high-integrity odor containment and absolute environmental protection makes these domes essential for:

Automotive Collection Centers: Managing diverse waste streams from engine and transmission oil changes.

Industrial Recycling Hubs: Storing large volumes of used lubricants before re-refining.

Marine Sludge Facilities: Providing secure storage for waste oils collected from shipping vessels in port areas.

Manufacturing Plants: Where used process oils must be held in a way that protects local air quality.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment for the waste management and energy sectors. Our approach to Aluminum Geodesic Dome Roofs for Welded Stainless Steel Used Motor Oil Storage Tanks is defined by a commitment to technical precision and environmental safety:

Odor-Containment Engineering: We design geodesic dome systems specifically to maximize gas-tightness and eliminate fugitive emissions.

Advanced Manufacturing Standards: Our facility utilizes high-grade aluminum alloys and precision-welded stainless steel to ensure the entire tank structure is a seamless, corrosion-resistant barrier.

Global Technical Support: We provide expert technical supervision for the assembly of clear-span domes and tank shells worldwide, ensuring absolute reliability for hazardous waste storage.

Conclusion

In the modern world of industrial recycling, the quality of storage infrastructure is the first line of defense against environmental pollution. Aluminum Geodesic Dome Roofs for Welded Stainless Steel Used Motor Oil Storage Tanks provide the most effective barrier against noxious odors and volatile organic compounds. By prioritizing a design that effectively contains odors for a cleaner environment, operators protect the health of their personnel and the surrounding community. When these tanks are reinforced with the maintenance-free protection of an aluminum dome, they represent a world-class solution that balances safety, durability, and operational excellence.