-

Glass Fused To Steel Tanks (463)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (210)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Aluminum Geodesic Dome Roof for Welded Stainless Steel Bitumen Tanks: Helps Maintain Thermal Efficiency and Contains Fumes during the Storage of Heavy Bituminous Products

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

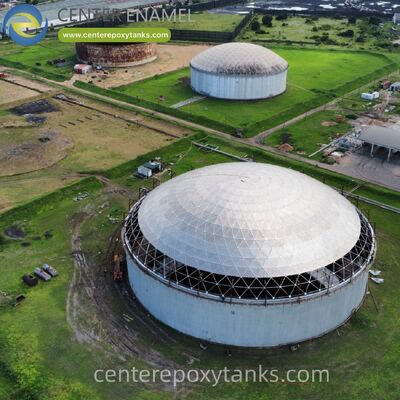

Aluminum Geodesic Dome Roof for Welded Stainless Steel Bitumen Tanks: Helps Maintain Thermal Efficiency and Contains Fumes during the Storage of Heavy Bituminous Products

Bitumen, a dense and highly viscous form of petroleum used primarily in road construction and roofing, presents some of the most extreme challenges in the storage industry. To remain in a liquid state for pumping and processing, bitumen must be stored at very high temperatures, often exceeding the boiling point of water. This requirement leads to significant energy consumption and the release of heavy, pungent fumes. Aluminum Geodesic Dome Roofs for Welded Stainless Steel Bitumen Tanks represent a specialized engineering solution for these high-temperature applications. This system helps maintain thermal efficiency and contains fumes during the storage of heavy bituminous products by creating a sealed, clear-span environment that acts as a natural insulator. By combining the high-heat resilience of a welded stainless steel shell with the lightweight efficiency of an aluminum dome, operators can manage bitumen inventories with maximum energy economy and environmental responsibility.

Enhancing Thermal Efficiency and Energy Retention

The primary operational cost associated with bitumen storage is the continuous heating required to maintain the product's fluidity. Heat loss through the roof of a large-diameter tank can be immense, leading to massive energy bills and potential localized solidification of the product. The Aluminum Geodesic Dome Roof provides an innovative solution to this thermal challenge. Aluminum is a low-emissivity material, meaning it is exceptionally poor at radiating heat away into the atmosphere.

Furthermore, the geodesic dome structure creates a stable, dead-air headspace above the liquid bitumen. This air gap acts as a natural layer of insulation, significantly reducing convective heat loss. Because the dome is a clear-span structure, there are no internal support columns that could act as "thermal bridges," conducting heat from the hot bitumen directly out through the roof. This column-free design is essential for maintaining thermal efficiency. When paired with a welded stainless steel shell—which can be easily fitted with high-performance external insulation—the aluminum dome creates a "thermos-like" environment. This ensures that the heating systems can operate at lower intensities, extending the life of the heating coils and reducing the overall carbon footprint of the storage facility.

Advanced Fume Containment and Air Quality

Storing bitumen at high temperatures inevitably leads to the production of heavy, oily fumes and volatile organic compounds. These emissions are not only a nuisance to the local community due to their strong odor but can also pose health risks to facility personnel. Traditional bitumen tanks often utilize vented roofs that allow these fumes to escape freely. The Aluminum Geodesic Dome Roof addresses this through its precision-engineered, enclosed design.

The dome’s advanced batten-sealing system provides a hermetic seal that contains fumes during storage. By trapping the bituminous vapors within the tank's headspace, the dome allows for the integration of vapor recovery units or carbon scrubbers, which treat the air before it is released. This containment is a critical component of modern environmental compliance. Moreover, the clear-span nature of the dome ensures that there are no internal obstacles to vapor flow, making the fume extraction and treatment processes much more efficient. By isolating the hot bitumen from the external environment, the dome prevents the release of noxious odors and ensures that the facility remains a responsible industrial neighbor.

Structural Resilience and Material Longevity

The combination of welded stainless steel and an aluminum dome provides a storage solution with exceptional durability under extreme thermal stress. Bitumen storage can be aggressive; the high temperatures and the presence of sulfur compounds can lead to rapid oxidation and corrosion in standard carbon steel tanks. Welded stainless steel is the ideal material for the shell as it maintains its structural integrity and corrosion resistance even at the elevated temperatures required for bitumen.

The Aluminum Geodesic Dome Roof is similarly robust. It does not rust, scale, or require periodic painting, which is a significant advantage in a bitumen environment where the presence of sticky residues makes maintenance difficult and hazardous. The lightweight nature of the aluminum dome—which is roughly one-third the weight of a steel equivalent—reduces the mechanical load on the welded stainless steel shell, which is already under stress from thermal expansion. This weight reduction facilitates more stable structural performance over thousands of heating and cooling cycles. This reliability ensures that the facility avoids the costly shutdowns and safety risks associated with repairing or repainting traditional steel roofs.

Application Areas

The need for thermal retention and absolute fume control makes these domes essential for:

Asphalt and Bitumen Refineries: Maintaining feedstock at optimal temperatures for processing.

Road Construction Supply Hubs: Providing high-capacity storage for bulk bitumen distribution.

Maritime Bitumen Terminals: Where the combination of a stainless steel shell and an Aluminum Geodesic Dome Roof provides the best protection against coastal corrosion.

Roofing Material Manufacturing Plants: Storing various grades of heavy bituminous products for industrial use.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment for the heavy oil and bitumen sectors. Our approach to Aluminum Geodesic Dome Roofs for Welded Stainless Steel Bitumen Tanks is defined by a commitment to technical precision and energy efficiency:

Thermal-Performance Engineering: We design geodesic dome systems specifically to maximize heat retention and reduce energy consumption in high-temperature applications.

Advanced Manufacturing Standards: Our facility utilizes high-grade aluminum alloys and precision-welded stainless steel to ensure the entire tank structure is a seamless, heat-resilient barrier.

Global Technical Support: We provide expert technical supervision for the assembly of clear-span domes and tank shells worldwide, ensuring absolute reliability for heavy product storage.

Conclusion

In the specialized field of bitumen storage, the quality of infrastructure is a direct reflection of a facility's commitment to efficiency and environmental safety. Aluminum Geodesic Dome Roofs for Welded Stainless Steel Bitumen Tanks provide the most effective barrier against heat loss and fume release. By prioritizing a design that maintains thermal efficiency and contains fumes, operators protect their expensive energy resources and the health of the local environment. When these tanks are reinforced with the maintenance-free protection of an aluminum dome, they represent a world-class solution that balances safety, durability, and operational excellence.