-

Glass Fused To Steel Tanks (469)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

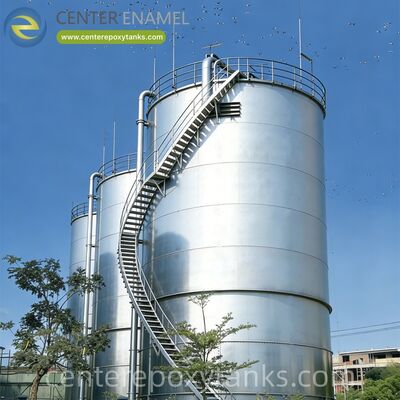

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (345)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Internal Floating Roof for Welded Stainless Steel Jet Fuel Storage Tanks: Ensures the Highest Level of Cleanliness and Aviation-Grade Purity

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W |

| Corrosion Resistance: | Suitable For Waste Water Salt Water, Sea Water, High Sulfur Crude Oil, Salt Fox, Organic And Inorganic Compounds | Elastic: | Same As Steel Sheet |

| Tank Body Color: | Customized Design | Coating Thickness: | Customized |

| Foundation: | Concrete | Steel Grade: | Stainless Steel |

| Highlight: | Internal floating roof for jet fuel tanks,Welded stainless steel storage tanks,Aviation-grade fuel tank cleanliness |

||

Product Description

Internal Floating Roof for Welded Stainless Steel Jet Fuel Storage Tanks: Ensures the Highest Level of Cleanliness and Aviation-Grade Purity

In the rigorous environment of aviation logistics, the quality of jet fuel is paramount. Aviation-grade kerosene, such as Jet A-1, must be kept free from particulates, surfactants, and moisture to ensure the safe operation of aircraft engines at high altitudes. Internal Floating Roofs for Welded Stainless Steel Jet Fuel Storage Tanks represent the peak of fuel preservation technology. This system ensures the highest level of cleanliness and aviation-grade purity by utilizing a buoyant deck that moves vertically with the liquid level. By eliminating the air-to-liquid interface, the system prevents the entry of atmospheric moisture and dust while suppressing the evaporation of volatile components, ensuring the fuel remains within strict technical specifications from the refinery to the wing.

Protecting Aviation Assets through Total Surface Isolation

The primary challenge in bulk jet fuel storage is the management of the tank's internal environment. In traditional fixed-roof tanks, the headspace above the fuel is a gateway for contamination. As ambient temperatures fluctuate, the tank draws in humid air, which condenses on the cold internal walls and settles into the fuel. This moisture can trigger microbial growth and degrade critical fuel additives. Internal Floating Roofs for Welded Stainless Steel Jet Fuel Storage Tanks solve this fundamental problem by physically occupying the surface area where air would otherwise reside.

Because the roof remains in direct contact with the fuel, there is no headspace for vapors to accumulate or for moisture to settle. This constant isolation is the core mechanism that ensures aviation-grade purity. To achieve a world-class standard of protection, modern airport fuel farms often integrate Aluminum Dome Roofs as an external protective shell. While the internal floating roof manages the fuel surface, the Aluminum Dome Roof acts as a superior, weather-tight cover. The geodesic design of the Aluminum Dome Roof is a clear-span structure, requiring no internal support columns. This is a decisive advantage; in traditional tanks, support columns penetrate the floating roof, creating gaps where moisture and dust can bypass the seals. By utilizing a column-free aluminum dome, the internal floating roof remains an unbroken barrier, providing a superior hermetic seal that guarantees the jet fuel remains clean.

Material Excellence and Advanced Thermal Management

Stainless steel is the premier choice for jet fuel storage due to its exceptional resistance to corrosion and its ability to maintain fuel integrity without the risk of internal rust or coating failure. The construction of Internal Floating Roofs for Welded Stainless Steel Jet Fuel Storage Tanks utilizes automated precision welding to ensure a seamless, high-strength primary container. Unlike carbon steel, stainless steel does not suffer from internal scaling. This is vital because even microscopic rust particles can damage the sensitive high-pressure fuel pumps and injectors in modern aircraft engines.

The addition of an external Aluminum Dome Roof reinforces this durability through advanced thermal regulation. Aluminum is highly reflective and naturally resistant to the corrosive gases often found in coastal airport environments. The Aluminum Dome Roof acts as a permanent thermal regulator; by reflecting a significant portion of solar radiation, it helps maintain a lower and more stable internal temperature for the stored fuel. This thermal stability is essential for maintaining cleanliness; lower temperatures significantly reduce the rate of chemical oxidation and prevent the formation of condensation on the internal tank walls. By keeping the tank environment cool and stable, the combination of a welded stainless steel shell and a maintenance-free aluminum dome results in a storage system that offers the highest level of vapor suppression, fuel safety, and structural longevity.

Enhancing Operational Efficiency and Maintenance Safety

The clear-span nature of the Aluminum Dome Roof also facilitates easier and more effective inspection and maintenance, which is critical for meeting strict aviation safety audits. Jet fuel tanks require frequent sampling and seal integrity checks to ensure no moisture or contaminants have bypassed the system. Without internal columns obstructing the view or the movement of the floating roof, technicians can more easily verify the condition of the deck and the effectiveness of the primary and secondary seals. This structural simplicity reduces the time the tank must spend offline during maintenance, maximizing the facility's operational throughput.

Furthermore, the absence of internal columns eliminates the risk of "hang-ups," where a floating roof might become stuck on a pillar during liquid level changes. In a large reservoir containing high-value jet fuel, a stuck roof can lead to a sudden exposure of the liquid surface or mechanical damage to the tank structure, creating a safety risk. By providing a clear-span environment, the aluminum dome ensures that the internal floating roof operates smoothly and predictably, maintaining its role to ensure product purity without interruption. This synergy between the stainless steel shell and the aluminum dome represents a world-class standard for industrial risk management and the protection of sensitive aviation assets.

Application Areas

The need for high-purity control and absolute structural resilience makes these tanks essential for:

International Airport Fuel Farms: Managing bulk inventories for global commercial flight operations.

Refinery Finished Product Hubs: Storing aviation fuel after final treatment and before dispatch.

Military Air Bases: Providing secure and stable storage for high-performance defense fuels.

Strategic National Reserves: Where long-term stability and minimal volume loss are required for energy security.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment for the aviation sector. Our approach to Internal Floating Roofs for Welded Stainless Steel Jet Fuel Storage Tanks is defined by a commitment to technical precision and product integrity:

Purity-Focused Engineering: We design tank systems specifically to maximize air exclusion and eliminate fuel degradation, frequently incorporating Aluminum Dome Roofs for a high-purity internal environment.

Advanced Manufacturing Standards: Our facility utilizes precision automated welding and high-grade stainless steel to ensure the tank shell is a seamless, robust barrier against environmental stress.

Global Technical Support: We provide expert technical supervision for the assembly of internal decks and geodesic domes worldwide, ensuring absolute reliability for mission-critical applications.

Conclusion

In the demanding world of aviation, the quality of storage infrastructure is the final link in the chain of flight safety. Internal Floating Roofs for Welded Stainless Steel Jet Fuel Storage Tanks provide the most effective barrier against the primary causes of fuel contamination and loss. By prioritizing a design that ensures the highest level of cleanliness and aviation-grade purity, operators protect their expensive inventories and the safety of the aircraft that rely on them. When these tanks are reinforced with the maintenance-free protection of an Aluminum Dome Roof, they represent a world-class solution that balances safety, durability, and operational excellence.