-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

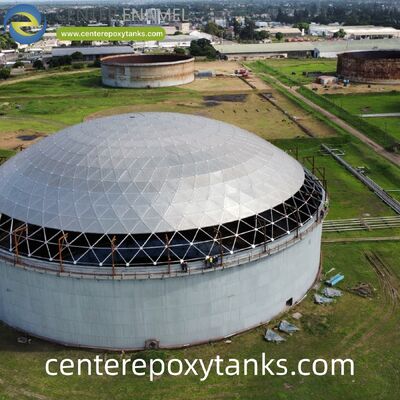

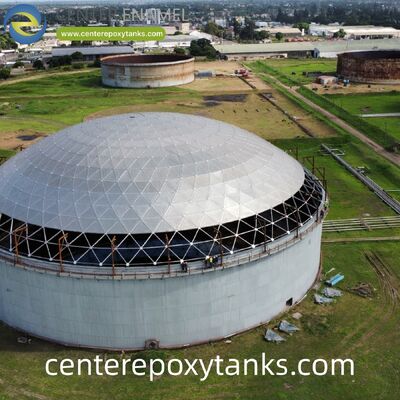

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Floating Roofs for Welded Stainless Steel Lubricant Oil Tank: Minimizes Air Contact to Preserve High-Value Industrial Lubricants

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

Floating Roofs for Welded Stainless Steel Lubricant Oil Tank: Minimizes Air Contact to Preserve High-Value Industrial Lubricants

In the high-precision world of industrial manufacturing and automotive engineering, the chemical stability of lubricant oils is the foundation of equipment longevity. Floating Roofs for Welded Stainless Steel Lubricant Oil Tanks represent a premium infrastructure solution designed for the storage of advanced base oils and finished industrial lubricants. These fluids are often complex chemical formulations containing specific additives that are highly sensitive to atmospheric interactions, particularly oxidation and moisture absorption. This specialized storage configuration is vital because it minimizes air contact to preserve high-value industrial lubricants, providing a hermetic, non-reactive environment that prevents the chemical breakdown, additive fallout, and oxidation that occur when high-grade oils are exposed to the open air.

The Critical Challenge of Additive Stability and Moisture Control

The greatest threat to a bulk lubricant’s performance is the absorption of atmospheric moisture. Lubricants are often hygroscopic, meaning they can draw water directly from the air. Even trace amounts of moisture can trigger the hydrolysis of essential additives—such as detergents, anti-wear agents, and friction modifiers—rendering the oil ineffective and potentially corrosive to precision bearings. In a traditional fixed-roof tank, the large headspace allows for constant "breathing," drawing in humid air as ambient temperatures fluctuate.

Floating Roofs for Welded Stainless Steel Lubricant Oil Tanks solve this by resting a precision-engineered, lightweight deck directly on the oil surface. By removing the air-to-liquid interface, the internal floating roof (IFR) ensures there is no volume of air where moisture can gather or where oxygen can catalyze thermal degradation.

To maximize this protection, the integration of Aluminum Dome Roofs has become a best practice for modern lubricant blending and distribution centers. While the floating roof manages the liquid surface, the Aluminum Dome Roof provides a superior, weather-tight external cover. The geodesic design of the Aluminum Dome Roof is a clear-span structure, meaning it requires no internal support columns. This is a vital advantage; in traditional tanks, support columns penetrate the floating roof, creating small gaps where moist air can bypass the seal. By utilizing a column-free aluminum dome, the internal floating roof remains entirely continuous, providing a superior hermetic seal that protects the lubricant's chemical balance.

Material Purity and Environmental Control

Stainless steel is selected for these applications due to its exceptional resistance to oxidation and its non-reactive nature. The construction of Floating Roofs for Welded Stainless Steel Lubricant Oil Tanks utilizes automated precision welding to create a seamless, high-integrity shell that does not require internal coatings or liners. This is critical for preventing particulate contamination, as coatings can flake or degrade over time. However, the external roof is the primary defense against the elements. This is where the Aluminum Dome Roof provides a decisive structural benefit.

Aluminum is naturally resistant to atmospheric corrosion and does not require maintenance painting, which is essential for maintaining a clean environment around high-value inventory. The Aluminum Dome Roof also acts as a permanent thermal regulator. By reflecting a significant portion of solar radiation, the aluminum structure helps maintain a lower and more stable internal temperature for the stored lubricant. This thermal stability is essential for preventing the intake of atmospheric humidity and reducing the rate of thermal oxidation. The combination of a high-strength stainless steel shell and a maintenance-free aluminum dome results in a storage system that offers the highest level of product security for the lubricant industry.

Enhancing Operational Efficiency and Quality Assurance

The clear-span nature of the Aluminum Dome Roof also facilitates easier and more effective inspection and maintenance, which is critical for meeting strict quality control standards. High-purity lubricant tanks require frequent sampling to ensure the oil remains within its specified parameters. Without internal columns obstructing the view or the movement of the internal floating roof, technicians can more easily verify the condition of the deck and the effectiveness of the vapor seals. This structural simplicity reduces the time the tank must spend offline, maximizing the facility's operational throughput.

Furthermore, the absence of internal columns eliminates the risk of "hang-ups," where a floating roof might become stuck on a pillar during liquid level changes. In the precision environment of lubricant storage, a stuck roof can lead to a sudden exposure of the oil surface or mechanical damage to the tank structure. By providing a clear-span environment, the aluminum dome ensures that the internal floating roof operates smoothly and predictably, maintaining its role to minimize air contact to preserve high-value industrial lubricants without interruption. This synergy between the stainless steel shell and the aluminum dome represents a world-class standard for industrial fluid management.

Application Areas

The need for high-purity storage and total moisture control makes these tanks essential for:

Specialty Lubricant Blending Plants: Managing raw base oils and finished product inventories.

Automotive Distribution Hubs: Storing bulk motor oils for regional supply chains.

Aerospace Maintenance Facilities: Where lubricant purity is a matter of mission-critical safety.

Marine Engineering Centers: Where the combination of a stainless steel shell and an Aluminum Dome Roof provides protection against humid, salt-air environments.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment. Our approach to Floating Roofs for Welded Stainless Steel Lubricant Oil Tanks is defined by a commitment to quality and technical precision:

Purity-Centric Engineering: We design tank systems specifically to eliminate every possible path for contamination, frequently incorporating Aluminum Dome Roofs to ensure a column-free, high-purity internal environment.

Advanced Manufacturing Standards: Our facility utilizes precision automated welding and high-grade stainless steel to ensure the tank shell is a seamless, non-reactive barrier.

Global Technical Support: We provide expert technical supervision for the assembly of internal floating decks and geodesic domes worldwide, ensuring the system minimizes air contact to preserve high-value industrial lubricants with absolute reliability.

Conclusion

In the competitive world of high-precision industry, the quality of storage determines the performance of the product. Floating Roofs for Welded Stainless Steel Lubricant Oil Tanks provide the most effective barrier against the primary causes of oil degradation. By prioritizing a design that minimizes air contact to preserve high-value industrial lubricants, operators protect their expensive inventories and ensure the reliable performance of the systems that depend on them. When these tanks are reinforced with the maintenance-free protection of an Aluminum Dome Roof, they represent a world-class solution that balances safety, durability, and operational excellence.