-

Glass Fused To Steel Tanks (428)

-

Stainless Steel Tanks (433)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

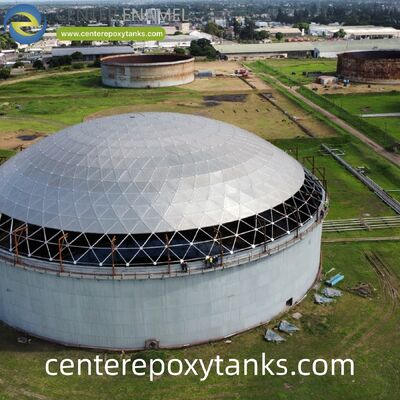

Aluminum Dome Roofs (1047)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (350)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Floating Roofs for Welded Stainless Steel Diesel Storage Tanks: Reduce Loss and Prevent Contamination in Various Climates

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

Floating Roofs for Welded Stainless Steel Diesel Storage Tanks: Reduce Loss and Prevent Contamination in Various Climates

In the global industrial landscape, diesel fuel serves as the primary energy source for heavy transport, construction, and emergency power generation. To ensure the reliability of these systems, the storage infrastructure must be capable of maintaining fuel stability across a wide range of environmental conditions. Floating Roofs for Welded Stainless Steel Diesel Storage Tanks represent a sophisticated engineering solution designed to meet these needs. While diesel is less volatile than gasoline, it remains susceptible to evaporation and atmospheric degradation. This specialized storage configuration is essential because it is designed to reduce loss and prevent contamination in various climates, providing a secure environment that shields the fuel from the damaging effects of humidity, temperature fluctuations, and airborne pollutants.

Combating Evaporation and Thermal Breathing

The primary challenge in diesel storage is the management of the air-liquid interface within the tank. Even though diesel has a lower vapor pressure than lighter fuels, it still experiences "breathing losses" as the tank heats up during the day and cools at night. In a traditional fixed-roof tank, this cycle draws in fresh air and expels fuel vapors, leading to long-term inventory loss. Floating Roofs for Welded Stainless Steel Diesel Storage Tanks address this by utilizing a precision-engineered internal floating deck that rests directly on the liquid surface.

By removing the headspace between the fuel and the roof, the internal floating roof (IFR) effectively suppresses the formation of vapors. This is a critical mechanism to reduce loss and prevent contamination in various climates. To enhance this protection, many modern facilities integrate Aluminum Dome Roofs into their storage architecture. While the floating roof manages the surface of the fuel, the Aluminum Dome Roof acts as a high-performance external shield. The geodesic design of the Aluminum Dome Roof is a clear-span structure, meaning it requires no internal support columns. This is a vital advantage for diesel storage; in traditional tanks, support columns penetrate the floating roof, creating potential leak paths for vapors and entry points for moisture. By utilizing a column-free aluminum dome, the internal floating roof remains entirely continuous, providing a superior hermetic seal.

Material Integrity and Moisture Prevention

In humid or coastal climates, moisture ingress is the leading cause of diesel degradation. Water in diesel tanks can lead to the growth of "diesel bugs"—microbial colonies that clog filters and corrode engine components. The choice of welded stainless steel for the tank shell is a proactive defense against these issues. Stainless steel provides a naturally smooth, non-porous, and corrosion-resistant surface that does not require the internal coatings often found in carbon steel tanks. The construction of Floating Roofs for Welded Stainless Steel Diesel Storage Tanks utilizes automated precision welding to ensure a seamless primary container.

The external Aluminum Dome Roof further reinforces this defense by providing a secondary layer of climate control. Aluminum is highly reflective and naturally resistant to corrosion from salt air and rain. The Aluminum Dome Roof acts as a permanent thermal regulator; by reflecting a significant portion of solar radiation, it helps maintain a stable internal temperature. This stability is crucial in preventing the condensation of water vapor on the inner walls of the tank. By keeping the fuel cool and dry, the combination of a welded stainless steel shell and a maintenance-free aluminum dome results in a storage system that offers the highest level of product security in any climate.

Enhancing Operational Efficiency and Maintenance Safety

The clear-span nature of the Aluminum Dome Roof also facilitates easier and more effective inspection and maintenance, which is critical for meeting strict environmental and safety regulations. Diesel tanks require periodic sampling and seal integrity checks to ensure the fuel remains within its specified parameters. Without internal columns obstructing the view or the movement of the internal floating roof, technicians can more easily verify the condition of the deck and the primary/secondary seals. This structural simplicity reduces the time the tank must spend offline, maximizing the facility's operational throughput.

Furthermore, the absence of internal columns eliminates the risk of "hang-ups," where a floating roof might become stuck on a pillar during liquid level changes. In a diesel reservoir, a stuck roof can lead to a sudden exposure of the fuel surface or mechanical damage to the deck. By providing a clear-span environment, the aluminum dome ensures that the internal floating roof operates smoothly and predictably, maintaining its role to reduce loss and prevent contamination in various climates without interruption. This synergy between the stainless steel shell and the aluminum dome represents a world-class standard for industrial fluid management.

Application Areas

The need for climate-resilient storage and contamination control makes these tanks essential for:

Strategic Diesel Reserves: Where long-term stability and fire hazard mitigation are required for national security.

Mining and Remote Industrial Sites: Storing bulk diesel in harsh environments where fuel quality is critical for heavy machinery.

Maritime and Port Facilities: Where the combination of a stainless steel shell and an Aluminum Dome Roof provides the best protection against coastal corrosion.

Emergency Power Hubs: Ensuring that backup diesel supplies for hospitals and data centers remain ready for immediate use.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in providing high-performance industrial containment for the energy sector. Our approach to Floating Roofs for Welded Stainless Steel Diesel Storage Tanks is defined by a commitment to technical precision and product integrity:

Climate-Focused Engineering: We design tank systems specifically to maximize moisture rejection and thermal stability, frequently incorporating Aluminum Dome Roofs to ensure a column-free internal environment.

Advanced Manufacturing Standards: Our facility utilizes precision automated welding and high-grade stainless steel to ensure the tank shell is a seamless, non-reactive barrier.

Global Technical Support: We provide expert technical supervision for the assembly of internal floating decks and geodesic domes worldwide, ensuring that the system will reduce loss and prevent contamination in various climates with absolute reliability.

Conclusion

In the demanding world of industrial energy storage, the quality of the infrastructure determines the reliability of the fuel supply. Floating Roofs for Welded Stainless Steel Diesel Storage Tanks provide the most effective barrier against the primary causes of fuel loss and contamination. By prioritizing a design that is intended to reduce loss and prevent contamination in various climates, operators protect their expensive inventories and ensure the reliable performance of the systems that depend on them. When these tanks are reinforced with the maintenance-free protection of an Aluminum Dome Roof, they represent a world-class solution that balances safety, durability, and operational excellence.