-

Glass Fused To Steel Tanks (422)

-

Stainless Steel Tanks (433)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1003)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (350)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

|

Detail Information |

|||

Product Description

Internal Floating Roofs for Welded Steel Used Motor Oil Storage Tanks: Suppresses Foul Odors and Harmful Gas Buildup

In the field of environmental management and industrial recycling, the containment of waste hydrocarbons requires specialized engineering to protect both personnel and the surrounding community. Internal Floating Roofs for Welded Steel Used Motor Oil Storage Tanks have become the primary solution for modern facilities looking to mitigate the environmental impact of their inventory. Used motor oil is often a complex chemical cocktail containing degraded lubricants, fuel residues, and various additives that can emit pungent and potentially toxic aromas. By implementing this high-integrity storage configuration, a facility effectively suppresses foul odors and harmful gas buildup, ensuring that operations remain compliant with air quality standards and occupational safety regulations.

Engineering a Total Vapor Barrier

The primary challenge in managing used motor oil is the "breathing" effect of the storage vessel. As ambient temperatures rise or as more oil is pumped into the tank, displaced air saturated with chemical fumes is forced out into the atmosphere. This is the root cause of the intense odors associated with recycling centers. Internal Floating Roofs for Welded Steel Used Motor Oil Storage Tanks address this by eliminating the air-to-liquid interface. The floating deck rests directly on the oil surface, trapping the volatile organic compounds (VOCs) within the liquid phase.

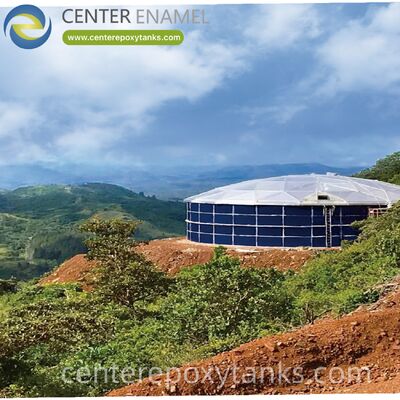

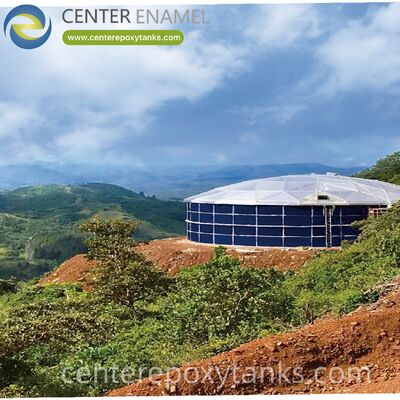

To maximize the containment efficiency of these systems, the use of Aluminum Dome Roofs is highly recommended. While the internal floating roof manages the surface of the waste oil, the Aluminum Dome Roof provides an essential, weather-tight external cover. The geodesic design of the Aluminum Dome Roof is a clear-span structure, meaning it requires no internal support columns. This is a vital advantage for used oil storage; in traditional tanks, support columns penetrate the floating roof, creating small gaps where hazardous fumes can escape. By utilizing a column-free aluminum dome, the internal floating roof can remain entirely continuous, providing a superior seal that suppresses foul odors and harmful gas buildup with near-perfect efficiency.

Durability and Environmental Security

Used motor oil can be surprisingly corrosive due to the presence of acids and moisture accumulated during the engine's lifecycle. A fully welded steel shell provides the structural strength and seamless construction required to prevent leaks. However, the upper part of the tank is often exposed to corrosive fumes that can degrade traditional steel roofs. This is where the Aluminum Dome Roof offers a decisive benefit. Aluminum is naturally resistant to the corrosive gases typically found in used oil environments, such as sulfur compounds.

Furthermore, the Aluminum Dome Roof prevents rainwater from entering the tank and mixing with the waste oil. Water ingress is a major concern in oil recycling; it complicates the refining process and can cause the internal floating roof to become unbalanced or sink. By providing a maintenance-free, weather-tight seal, the Aluminum Dome Roof ensures the internal safety mechanisms are always in peak condition. This synergy between the welded steel shell, the internal floating deck, and the external aluminum dome results in a storage system that is as durable as it is environmentally responsible.

Enhancing Operational Efficiency and Safety

Beyond odor control, the use of Internal Floating Roofs for Welded Steel Used Motor Oil Storage Tanks significantly improves the safety profile of the entire facility. By suppressing the formation of flammable vapor-air mixtures in the headspace of the tank, the system inherently reduces the risk of fire or explosion. This is particularly important for waste oil, which may have an unpredictable flashpoint due to contamination with gasoline or solvents.

The addition of an Aluminum Dome Roof further enhances this safety by providing a non-sparking, lightning-protective cover. The aluminum geodesic structure reflects solar radiation, helping to maintain a lower and more stable internal temperature. This thermal regulation minimizes the expansion and contraction of the stored oil, which in turn reduces the physical stress on the internal floating roof seals. Consequently, the facility benefits from reduced maintenance requirements and a longer service life for the internal sealing components, all while ensuring that the storage environment remains secure and the surrounding air remains clean.

Application Areas

The critical need for odor and fume control makes these tanks essential for several sectors:

Used Oil Recycling Facilities: Managing large-scale collection points for automotive and industrial lubricants.

Industrial Maintenance Hubs: Collecting waste fluids from manufacturing plants before transport.

Port Reception Facilities: Handling marine lubricants and waste oil from shipping vessels.

Hazardous Waste Treatment Sites: Where the combination of a welded shell and an Aluminum Dome Roof provides the best protection against toxic fume release.

Company Advantage and Comprehensive Service

Center Enamel is a leader in the design of specialized containment systems. Our approach to Internal Floating Roofs for Welded Steel Used Motor Oil Storage Tanks is defined by a commitment to environmental protection:

Odor-Control Engineering: We design tank systems specifically to eliminate gas release points, frequently integrating Aluminum Dome Roofs to ensure a column-free, high-containment internal environment.

Advanced Fabrication Standards: Our facility utilizes precision welding and high-strength materials to ensure the tank shell is a seamless barrier against leaks and chemical stress.

Turnkey Installation Expertise: We provide on-site technical supervision to ensure the internal floating roof and external geodesic dome are installed to the highest tolerances, guaranteeing the system suppresses foul odors and harmful gas buildup effectively.

Conclusion

For facilities managing used hydrocarbons, the integrity of the seal is the integrity of the community relationship. Internal Floating Roofs for Welded Steel Used Motor Oil Storage Tanks offer the most reliable technology for preventing the escape of nuisance and hazardous gases. By prioritizing a design that suppresses foul odors and harmful gas buildup, operators protect their workers and the local environment. When these tanks are reinforced with the maintenance-free protection of an Aluminum Dome Roof, they represent a world-class solution that balances operational efficiency with structural longevity.