-

Glass Fused To Steel Tanks (422)

-

Stainless Steel Tanks (433)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1003)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (350)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Internal Floating Roofs for Welded Steel Industrial Oil Tanks: Secures Bulk Inventory While Maintaining Fluid Integrity

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

Internal Floating Roofs for Welded Steel Industrial Oil Tanks: Secures Bulk Inventory While Maintaining Fluid Integrity

In the heart of modern manufacturing and power generation, industrial lubricants and process oils serve as the lifeblood of machinery. Internal Floating Roofs for Welded Steel Industrial Oil Tanks represent a specialized engineering approach to the large-scale storage of these vital fluids. Industrial oils, including turbine oils, transformer oils, and heavy machine lubricants, are high-value assets that require precise storage conditions to prevent degradation. This advanced storage configuration is essential because it secures bulk inventory while maintaining fluid integrity, preventing the ingress of atmospheric contaminants and the onset of chemical breakdown that can occur during long-term storage.

Preventing Oxidation and Contamination at the Source

The primary threat to the longevity of industrial oil is exposure to the atmosphere. When bulk oil is stored in a standard fixed-roof tank, it is subjected to constant contact with oxygen and moisture. Oxygen triggers oxidative instability, which increases the oil's acidity and leads to the formation of varnish and sludge—substances that are catastrophic for precision bearings and high-speed turbines. Internal Floating Roofs for Welded Steel Industrial Oil Tanks address this by eliminating the air-to-liquid interface. The floating deck rests directly on the oil, effectively "sealing" the product from the air.

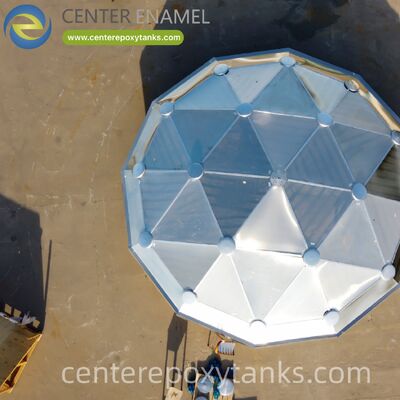

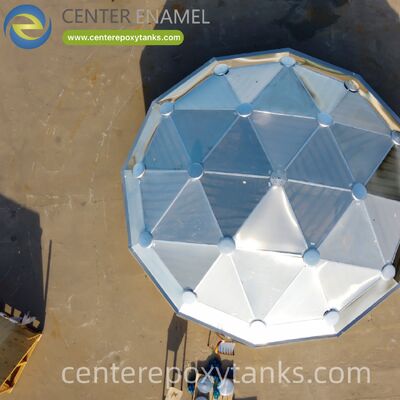

To further elevate the protection of these sensitive fluids, the integration of Aluminum Dome Roofs has become a best practice. While the internal floating roof manages the liquid surface, the Aluminum Dome Roof provides a superior, weather-tight external cover. The geodesic design of the Aluminum Dome Roof is a clear-span structure, meaning it requires no internal support columns. This is a critical advantage for industrial oil storage; in traditional tanks, support columns penetrate the floating roof, creating small gaps where moist air can enter. By utilizing a column-free aluminum dome, the internal floating roof remains entirely continuous, providing a superior seal that secures bulk inventory while maintaining fluid integrity with near-perfect efficiency.

Structural Durability and Particulate Control

Industrial oils must be kept extremely clean to meet ISO cleanliness standards. The construction of Internal Floating Roofs for Welded Steel Industrial Oil Tanks utilizes heavy-gauge steel and precision welding to create a seamless, leak-proof primary container. However, the choice of roof material is equally important for maintaining purity. Traditional steel roofs can corrode over time, shedding rust or paint flakes into the tank. This is where the Aluminum Dome Roof provides a decisive benefit. Aluminum is naturally corrosion-resistant and does not require painting, ensuring that no particulate matter from the roof can ever fall into the tank and contaminate the oil.

Furthermore, the Aluminum Dome Roof acts as a thermal shield, reflecting a significant portion of solar radiation. This thermal regulation helps maintain a stable internal temperature for the stored oil, which is crucial for preventing the "breathing" of the tank. By reducing temperature fluctuations, the system minimizes the expansion and contraction of the air inside the tank, further assisting the internal floating roof in its mission of securing bulk inventory while maintaining fluid integrity. The combination of a high-strength welded shell and a maintenance-free aluminum dome results in a storage system that offers the highest level of product security while requiring minimal long-term operational expenditure.

Enhancing Operational Efficiency and Asset Longevity

The clear-span nature of the Aluminum Dome Roof also facilitates easier inspection and maintenance. Without internal columns obstructing the view or the movement of the internal floating roof, technicians can more easily verify the integrity of the vapor seals and the cleanliness of the deck. This structural simplicity reduces the time the tank must spend offline for regulatory inspections. Furthermore, the absence of internal columns eliminates the risk of "hang-ups" where the floating roof might become stuck on a pillar, which would immediately break the protective seal and expose the industrial oil to the atmosphere.

By investing in a high-integrity storage system, facilities can significantly extend the service life of their industrial oil reserves. Reducing the rate of oxidation and moisture ingress means that the oil remains within its performance specifications for longer periods, reducing the frequency of expensive oil replacement and filtration cycles. This results in a direct financial benefit to the operator, all while ensuring that the high-value machinery served by the oil remains protected from contaminated or degraded lubricants.

Application Areas

The need for high-purity and stable oil storage makes these tanks essential for several key industrial sectors:

Power Generation Plants: Storing large volumes of turbine and transformer oils for critical infrastructure.

Heavy Manufacturing Facilities: Managing bulk lubricants for hydraulic presses and automated assembly lines.

Mining and Material Processing: Holding specialized oils in harsh environments where dust and moisture are prevalent.

Lubricant Blending and Distribution Hubs: Where the combination of a welded shell and an Aluminum Dome Roof ensures a zero-contamination environment for high-grade products.

Company Advantage and Comprehensive Service

Center Enamel is recognized globally for its expertise in high-performance industrial containment. Our approach to Internal Floating Roofs for Welded Steel Industrial Oil Tanks is defined by a commitment to quality and technical precision:

Integrity-Focused Engineering: We design tank systems specifically to eliminate air contact and prevent particulate contamination, frequently incorporating Aluminum Dome Roofs to ensure a column-free, high-purity internal environment.

Advanced Manufacturing Standards: Our facility utilizes precision automated welding and high-grade materials to ensure the tank shell is a seamless barrier against leaks and structural stress.

Turnkey Installation Expertise: We provide on-site technical supervision to ensure the internal floating roof and external geodesic dome are installed to the highest tolerances, guaranteeing the system secures bulk inventory while maintaining fluid integrity effectively.

Conclusion

In the demanding world of industrial operations, the quality of the stored oil determines the reliability of the system. Internal Floating Roofs for Welded Steel Industrial Oil Tanks provide the most effective barrier against the primary causes of fluid degradation. By prioritizing a design that secures bulk inventory while maintaining fluid integrity, operators protect their most valuable assets and ensure consistent performance. When these tanks are reinforced with the maintenance-free protection of an Aluminum Dome Roof, they represent a world-class solution that balances safety, durability, and operational excellence.