-

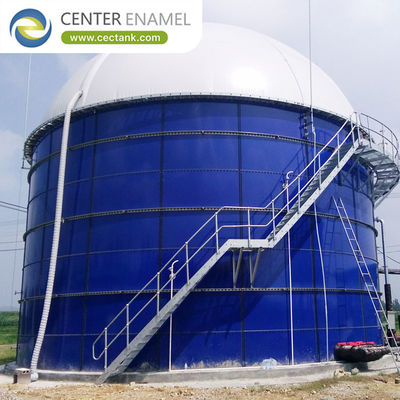

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Double Membrane Biogas Holder for a Chemical Wastewater Treatment Plant: Used to Store Biogas Generated from Organic Chemical Waste Streams

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001:2008 , AWWA D103 , OSHA , BSCI |

| Model Number: | Single & Double Membrane Roofs |

| Minimum Order Quantity: | 1+ |

| Price: | 0~99999 |

| Packaging Details: | Wooden Package(Customized) |

| Delivery Time: | 45days+ |

| Payment Terms: | T/T, L/C |

|

Detail Information |

|||

Product Description

Double Membrane Biogas Holder for a Chemical Wastewater Treatment Plant: Used to Store Biogas Generated from Organic Chemical Waste Streams

A Chemical Wastewater Treatment Plant faces the daunting task of managing high-strength, often toxic or corrosive, organic chemical waste streams produced during manufacturing. When suitable, anaerobic digestion (AD) is employed as a highly effective method to stabilize the effluent and reduce its organic load. This process generates a significant volume of methane-rich biogas. For the plant to maximize energy recovery, ensure safety, and maintain strict environmental compliance, the biogas must be reliably and securely stored. This requires a solution that is durable, hermetically sealed, and engineered specifically to handle the gas produced from complex organic chemical processes.

The Double Membrane Biogas Holder is the optimal technology for this specialized industrial application. It is used to store biogas generated from organic chemical waste streams. Installed either as an integrated flexible roof on the digester or as a compact, free-standing unit , this holder provides a dynamic, hermetic reservoir. This system ensures every cubic meter of gas is captured, pressure fluctuations are safely managed, and a stable, continuous supply is maintained for downstream utilization (e.g., boilers or CHP units), turning a challenging waste product into a valuable energy asset for the chemical plant.

Product Advantages for Chemical Industry Biogas Management

Center Enamel’s Double Membrane Biogas Holders are meticulously engineered to handle the substantial gas output and challenging environment characteristic of chemical waste treatment, maximizing the efficiency and safety of these high-load industrial plants.

Resilience to Corrosive Industrial Gas

Biogas generated from the digestion of organic chemical waste streams can be highly corrosive due to moisture, elevated temperatures, and specific trace elements. The balloon is constructed from specialized, multi-layered composite fabric, which is selected for its exceptional durability and, critically, resistance to corrosive elements. This superior resistance is crucial for the long-term integrity of the gas-tight seal, ensuring reliable operation, minimizing fugitive methane emissions, and reducing maintenance costs in this demanding industrial environment.

Integrated Gas Capture and Supply Stability

The system acts as the integrated flexible roof of the digester tank, ensuring maximum gas capture efficiency by collecting the gas instantly. The inner membrane's volume dynamically expands and contracts to accommodate the natural volume fluctuations in biogas production inherent in chemical processing cycles. This acts as a perfect buffer, stabilizing the low pressure and supply of gas to the plant’s utilization equipment. This stability is critical for continuous industrial operation, protecting sensitive downstream machinery.

Support for Aluminum Dome Roofs

Where maximum corrosion resistance and structural integrity are essential, the Double Membrane Holder can be installed on or adjacent to a tank protected by an Aluminum Dome Roof . While the membrane system provides the essential flexible gas-tight envelope, the aluminum dome offers superior long-term corrosion protection and structural support for the entire digester tank structure, enhancing overall system durability in challenging chemical environments.

Company Advantages

Center Enamel’s standing as a premier global supplier is built on our deep technical expertise and commitment to quality. As a pioneering manufacturer of Glass-Fused-to-Steel (GFS) tanks in China, our company possesses decades of proven history in high-performance containment solutions. Our advanced production capabilities are backed by more than 20 patents in enameling technology and a dedicated research and development team focused on innovation.

Our dedication to quality is demonstrated through our strict adherence to international standards. Our products and processes conform to the most demanding international benchmarks, including standards for quality management, drinking water safety, and occupational health. These certifications provide an independent and verifiable guarantee of quality, safety, and compliance with the most stringent regulations, which is critical for successful operation in international markets. This commitment, combined with our proven global track record of successful projects in over 100 countries, makes us a reliable and expert partner for any industrial biogas project.

Product Application Areas

Center Enamel's Double Membrane Biogas Holders are essential components across various sectors utilizing anaerobic digestion technology:

Chemical Wastewater Treatment Plant: Used to store biogas generated from organic chemical waste streams.

Industrial Wastewater Treatment Plant: Captures and stores biogas generated during anaerobic effluent treatment.

Industry Park Wastewater Treatment Plant: Provides flexible, reliable gas storage for mixed industrial effluent.

Industrial Biogas Plants: Offers high-volume, flexible storage for efficient industrial energy production.

Global Reach and Proven Excellence: Project Cases

Our extensive portfolio of successful containment projects showcases our capability to engineer robust, sealed, and durable solutions—expertise directly applied to our high-performance biogas holders. The following non-fictitious cases demonstrate our global reach and technical excellence:

Inner Mongolia Xing'an League Bio-natural Gas Project: We supplied 4 tanks for a large-scale bio-natural gas project in Inner Mongolia, showcasing our capability in major energy recovery infrastructure.

Shandong Liaocheng Food Waste Treatment Project: We provided 1 tank for a food waste treatment facility in Shandong, China, highlighting our role in high-volume waste-to-energy solutions.

Muyuan Group Suining 4th Farm Livestock Wastewater Project: For a major agricultural client, we supplied 2 tanks for a livestock wastewater project, demonstrating our expertise in large-volume, sealed agricultural containment critical for biogas management.

Conclusion

For a Chemical Wastewater Treatment Plant, the Double Membrane Biogas Holder is the definitive solution for resource recovery and safety. By being used to store biogas generated from organic chemical waste streams, it ensures the efficient, safe, and continuous utilization of the methane-rich fuel, enabling the plant to achieve energy self-sufficiency and superior environmental performance.