-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

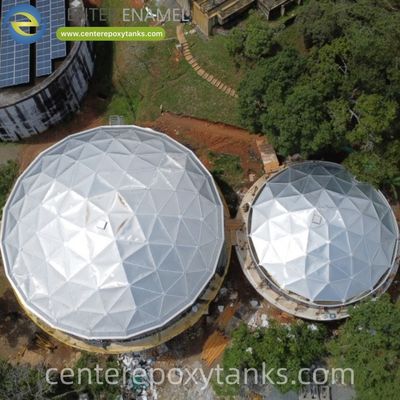

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Internal Floating Roof for Blended Crude Oil Tanks: Effectively Suppresses Vapor Release from Complex, Volatile Crude Oil Mixtures

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

Internal Floating Roof for Blended Crude Oil Tanks: Effectively Suppresses Vapor Release from Complex, Volatile Crude Oil Mixtures

Blended crude oil tanks store crude oil that has been mixed from various sources to meet specific refinery input requirements or quality standards. These mixtures are often complex and highly volatile, containing a significant volume of light hydrocarbon fractions that readily flash off as vapor. Storing these volatile mixtures in fixed-roof tanks results in massive evaporation losses (a major financial drain) and the release of high concentrations of Volatile Organic Compounds (VOCs) and other harmful gases like hydrogen sulfide. To mitigate these economic and environmental liabilities, the installation of an Internal Floating Roof (IFR) is the essential solution. The IFR is specifically engineered to effectively suppress vapor release from complex, volatile crude oil mixtures, ensuring both regulatory compliance and maximum resource recovery. Center Enamel, a global leader in advanced containment solutions, provides robust IFR systems tailored for the dynamic nature of crude oil storage.

Technology and Performance: Dynamic Containment for Mixed Vapors

The Internal Floating Roof (IFR) is a sturdy, sealed deck installed within a fixed-roof tank, designed to float directly on the surface of the blended crude oil. The IFR's core function is to establish a continuous, physical barrier that eliminates the large vapor space where volatile compounds accumulate. This barrier is especially critical for blended crude, as the high volatility and complexity of the mixture lead to rapid vapor generation. IFRs are typically constructed from non-corrosive, non-sparking materials like aluminum, with robust perimeter seals engineered to handle the typical temperature and density variations found in crude oil storage. This technology ensures:

Superior Vapor Suppression: The IFR acts as a total physical seal, suppressing the rapid release of volatile vapors from the complex crude oil mixture. This action drastically reduces evaporative loss of valuable light ends, which directly improves the financial yield of the stored crude oil asset. The IFR's seal integrity is paramount for capturing these high-volume vapors.

VOC and Gas Emission Control: By eliminating the vapor space, the IFR significantly reduces the emission of VOCs and other hazardous gases, such as sulfur compounds, into the atmosphere. This is vital for facilities located in areas with strict air quality mandates, providing a reliable, passive means of environmental compliance.

Enhanced Fire Safety: The IFR removes the explosive fuel-air mixture layer from the tank headspace. This critical action reduces the fire and explosion hazard inherent in storing highly volatile crude, protecting the facility from risks associated with lightning strikes or static discharge. This is a non-negotiable safety feature in volatile crude storage.

Key Advantages: Economic Recovery and Safety Assurance

The strategic deployment of an Internal Floating Roof in blended crude oil tanks delivers substantial long-term benefits focused on operational security and financial stability. Maximized Economic Recovery is the paramount advantage. The amount of valuable light crude components saved from evaporation provides a rapid and substantial return on the IFR investment, ensuring that the maximum possible volume of the highly-traded crude is preserved for refining.

Regulatory and Environmental Security is a crucial benefit. Given the high volume of emissions from volatile crude, the IFR provides a proven, reliable, and continuous method for meeting stringent environmental protection agency (or equivalent) standards for VOC emission reduction. This provides regulatory certainty and allows for uninterrupted operation.

Operational Efficiency and Durability means the IFR operates passively, moving with the liquid level and requiring minimal maintenance. Its use protects the fixed steel roof from the corrosive effects of concentrated vapors, thereby extending the service life of the entire tank asset.

Application Areas: Critical for Volatile Hydrocarbon Storage

The Internal Floating Roof is an indispensable component for any fixed-roof tank storing volatile or complex petroleum mixtures where vapor control and safety are essential. The core application is Internal Floating Roof for Blended Crude Oil Tanks: Effectively suppresses vapor release from complex, volatile crude oil mixtures.

IFRs are vital across various hydrocarbon storage sectors. They are critical for Crude Oil Storage Tanks, where they suppress the release of volatile vapors. They are also essential for API 650 Oil Tanks, serving as the key feature that reduces VOC emissions and enhances fire safety in tanks built to that standard, and for Petrochemical Storage Tanks storing volatile chemical mixtures.

Company Advantage and Comprehensive Service

Center Enamel is committed to providing industry-leading containment solutions supported by a comprehensive service framework that guarantees project success from concept to completion:

Global Expertise and Custom Design: We provide IFR designs compliant with stringent international standards (API 650 Appendix H). Our engineering team excels at custom-designing IFR systems that are specifically optimized to handle the dynamic boiling point range and high volatility of blended crude, ensuring maximum seal efficiency and structural stability.

Advanced In-House Manufacturing: Utilizing cutting-edge production lines and precision manufacturing, we maintain strict quality control over every IFR component, ensuring dimensional accuracy and superior seal performance, which is vital for effective vapor suppression.

Turnkey Support and Installation Guidance: We offer a complete solution, including detailed installation manuals, supervision by experienced engineers, and global logistics management to ensure on-time delivery and seamless installation worldwide. Our services cover every stage of a project:

Engineering Design: Our designs conform to international standards, providing precise calculations and construction drawings.

Rigorous Quality Control: We perform multiple inspections to guarantee the integrity of our products.

Logistics and Delivery: Our international packaging standards are suitable for ocean shipment, and we ensure on-time delivery to project sites worldwide.

Expert Installation Support: We provide detailed installation guides and can offer on-site supervisors to assist local crews.

Conclusion

For fixed-roof blended crude oil tanks, the Internal Floating Roof is a mandatory component for responsible storage. Its proven ability to effectively suppress vapor release from complex, volatile crude oil mixtures is critical for maximizing economic return and ensuring compliance with strict safety and environmental standards. Center Enamel’s expertise provides the superior design and durable execution necessary for optimizing volatile crude storage performance.