-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

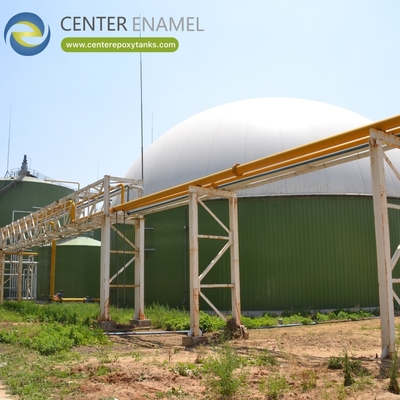

Biogas Tank for Breweries & Food Processing: The main container for biogas digestion.

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001:2008 , AWWA D103 , OSHA , BSCI |

| Model Number: | Single & Double Membrane Roofs |

| Minimum Order Quantity: | 1+ |

| Price: | 0~99999 |

| Packaging Details: | Wooden Package(Customized) |

| Delivery Time: | 45days+ |

| Payment Terms: | T/T, L/C |

|

Detail Information |

|||

Product Description

Biogas Tank for Breweries & Food Processing: The main container for biogas digestion.

The brewing and food processing industries are essential sectors of the global economy, providing a wide array of products enjoyed worldwide. However, their operations also generate a substantial amount of organic wastewater and byproducts that are high in biological oxygen demand (BOD) and chemical oxygen demand (COD). If not properly managed, this effluent can severely impact local ecosystems and place a heavy burden on municipal treatment systems. Historically, managing this waste has been a costly operational expense. However, with the advent of advanced anaerobic digestion technology, this waste can be transformed from a liability into a valuable asset. The organic content of the wastewater is converted into biogas, a clean, renewable energy source, which can be used to offset energy costs or generate electricity. The key to realizing this potential is an efficient and reliable system for housing the anaerobic digestion process. Without a robust and purpose-built reactor, the entire waste-to-energy system is at risk.

Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), a global leader in containment solutions, has engineered the ideal answer with its advanced Biogas Tanks. These tanks are meticulously designed and constructed to meet the rigorous demands of food processing and brewery environments. Utilizing robust Glass-Fused-to-Steel (GFS) technology, our tanks provide a secure and stable environment for microorganisms to efficiently convert organic waste into biogas. By offering a containment solution that is highly resistant to corrosion, easy to install, and built for long-term reliability, our tanks are fundamental to maximizing the efficiency of biogas production, ensuring responsible waste management, and helping plants reduce their operational costs.

Product Advantages

Center Enamel’s Biogas Tanks are a superior solution for anaerobic digestion, built to address the specific challenges of containing and processing organic waste from breweries and food processing facilities. The core of our technology lies in the use of high-quality materials and precision engineering, which ensures exceptional performance and durability. This innovative design offers a multitude of advantages that directly benefit biogas production and plant operation.

The primary advantage of our biogas tanks is their unmatched durability and corrosion resistance. The Glass-Fused-to-Steel technology creates an incredibly strong bond between enamel and steel, providing a non-porous and chemically inert surface. This unique coating makes the tanks highly resistant to the corrosive gases and acids produced during anaerobic digestion, ensuring a long service life with minimal maintenance. Unlike concrete or other traditional materials, GFS tanks do not suffer from spalling, cracking, or material degradation from prolonged exposure to harsh digester environments. This resistance ensures the structural integrity of the tank is maintained, providing a reliable and safe environment for the digestion process.

Another key advantage is the enhanced structural integrity and rapid installation. Our tanks are constructed from standardized, factory-coated panels that are bolted together on-site. This modular design simplifies the installation process, significantly reducing construction time and labor costs compared to traditional cast-in-place concrete tanks. The precision manufacturing of each panel ensures a perfect fit, creating a strong and reliable structure. This pre-fabricated system also allows for greater flexibility, as tanks can be easily expanded, relocated, or even disassembled if needed. The bolted design is a key differentiator, providing a robust solution that is both efficient to deploy and easy to maintain.

Furthermore, the design of our tanks allows for optimal process control and hygiene. The smooth, inert surface of the GFS panels prevents the buildup of bacteria and algae, which can interfere with the anaerobic digestion process. This hygienic surface ensures a clean environment that supports the health of the microbial community, leading to more stable and efficient biogas production. Additionally, the tanks can be equipped with various accessories and fittings for monitoring temperature, pressure, and pH levels, allowing for precise control over the digestion process. This adaptability, combined with the low maintenance requirements and superior containment capabilities, makes our biogas tanks a premier choice for any anaerobic digestion application.

Company Advantages

As a globally recognized leader in containment solutions, Center Enamel brings decades of experience and a deep commitment to excellence to every project. Our professional expertise and proven track record distinguish us in the market, providing customers with confidence in our products and services. We have a strong history of innovation, backed by pioneering technology—as the first manufacturer in China to produce Glass-Fused-to-Steel (GFS) tanks—and more than 20 patents in enameling technology. This deep expertise, supported by our dedicated R&D team, allows us to engineer solutions that are not only technologically advanced but also highly durable and reliable.

Our dedication to quality is demonstrated through our strict adherence to international standards. Our products and processes conform to the most demanding international benchmarks, including ISO 9001, NSF/ANSI 61, WRAS, and OSHA. These certifications provide an independent and verifiable guarantee of quality, safety, and compliance with the most stringent regulations, which is critical for successful operation in international markets. This commitment, combined with our proven global track record of successful projects in over 100 countries and collaborations with major international corporations, makes us a reliable and expert partner for any biogas project. We have a global distribution network and a team of experienced engineers who can provide expert support, from design and manufacturing to installation and after-sales service, ensuring that our products meet the highest standards of quality and performance.

Product Application Areas

Center Enamel's Biogas Tanks are a key component in a wide range of industrial and agricultural biogas projects, providing a reliable main container for anaerobic digestion. In breweries and food processing plants, these tanks are used to process organic waste and wastewater, including beer grains, food scraps, and wash-water. This helps facilities manage waste products responsibly while generating a valuable energy source. The tanks are also essential in municipal wastewater treatment plants for the treatment of sewage sludge, which helps municipalities reduce their environmental footprint and generate power for their operations. Additionally, they are critical to agricultural waste treatment facilities, where organic waste from livestock manure and other farm residues is processed to produce energy. By providing a secure and durable reactor for the anaerobic digestion process, these tanks help facilities handle their waste responsibly while simultaneously generating a reliable renewable energy source and controlling odors. The versatility of our biogas tanks makes them suitable for a diverse range of applications, from small-scale digesters to large, complex industrial biogas plants.

Global Reach and Proven Excellence: Project Cases

As a premier provider of bolted tanks and containment systems, Center Enamel has established a global footprint with numerous successful projects. The following non-fictitious cases, selected from our extensive portfolio, demonstrate our capacity to deliver high-quality biogas solutions for industrial and agricultural waste treatment.

Brazil Brewery Wastewater Treatment Project: We supplied 5 tanks with a total capacity of 25,500 cubic meters for a major brewery wastewater treatment project in Brazil. These tanks served as the core containers for the facility's anaerobic digestion process.

Vietnam Fish Processing Wastewater Project: We provided 2 tanks with a total capacity of 11,900 cubic meters for a fish processing plant in Vietnam. These tanks were an integral part of the plant’s system, used as the main reactors for the digestion of organic waste.

Germany Sugar Beet Factory Biogas Project: For a large-scale project in Germany, we supplied 4 tanks with a total capacity of 20,200 cubic meters. These tanks were used as the primary digestion vessels for treating organic waste from the sugar beet factory.

Conclusion

The secure and efficient containment of the anaerobic digestion process is a fundamental factor for a successful biogas plant. Center Enamel's Biogas Tanks offer a technologically advanced, reliable, and cost-effective solution for this critical need. By providing a durable and corrosion-resistant main container, these tanks empower plant operators to maximize the efficiency of biogas production and reduce long-term operational costs. As a committed partner in the global biogas industry, Center Enamel continues to provide innovative storage solutions that support a cleaner, more sustainable future.