-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

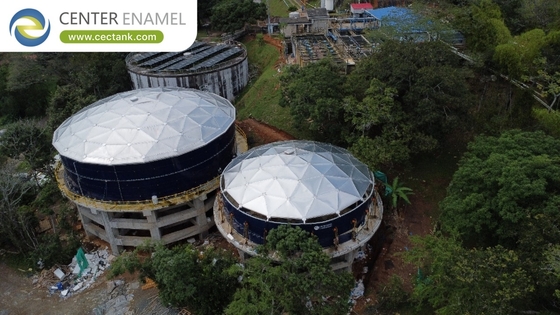

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Floating Roof for Crude Palm Oil (CPO) Tanks: Maintains oil quality and prevents oxidation

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

Product Description

Floating Roof for Crude Palm Oil (CPO) Tanks: Maintains oil quality and prevents oxidation

The global palm oil industry is a cornerstone of the food, cosmetics, and bio-energy sectors, but its success hinges on the integrity of the crude palm oil (CPO) during storage. CPO is a valuable yet sensitive commodity; exposure to atmospheric oxygen and contaminants can lead to oxidation, which degrades its quality and reduces its market value. To safeguard this critical resource, floating roof tanks have become the preferred storage solution. By creating a physical barrier between the CPO and the atmosphere, this advanced containment technology prevents oxidation and contamination, ensuring the oil maintains its quality from the mill to its final destination. The floating roof tank is a powerful example of how specialized engineering can fundamentally transform the preservation and value of a crucial agricultural commodity, setting a new benchmark for the entire industry.

The Core Technology of Floating Roof Tanks

The concept behind a floating roof tank is to eliminate the dangerous vapor space that exists in conventional tanks. A floating roof is a physical structure that rests directly on the surface of the stored liquid. As the liquid level in the tank rises or falls, the roof moves along with it. This design prevents the CPO from coming into direct contact with atmospheric oxygen, which is the primary cause of oxidation and quality degradation. This is the primary function of the floating roof in this application: to protect the product's integrity and value.

Furthermore, by sealing the liquid from the external atmosphere, the floating roof cuts down on evaporation. This directly translates into a significant decrease in product loss and a substantial economic benefit. More importantly, it serves as a barrier against external contaminants like dust, rain, and debris, ensuring the CPO remains pure. This dual function of product conservation and quality preservation makes the floating roof a fundamental operational imperative for CPO storage.

Floating roofs are typically constructed from aluminum or steel and are equipped with a series of seals that close the narrow gap between the edge of the roof and the tank wall. These seals ensure the vapor-tight integrity of the containment.

Center Enamel's Advantages

As a manufacturer of these advanced storage solutions, Center Enamel operates on a holistic and client-focused model. Our market leadership is a direct result of continuous innovation and a commitment to quality. Our manufacturing processes adhere to the most stringent international standards, with comprehensive certifications including ISO 9001 and EN1090, affirming our dedication to structural integrity and reliable performance. We offer a comprehensive "Full Chain Service" that covers every phase of a project, from initial engineering consultation to efficient on-site installation and global after-sales support. This integrated approach ensures a seamless execution and enduring performance for every project.

Project Cases: Floating Roof Tanks in Action

The following cases, based on common industrial applications, illustrate how this specialized technology provides a robust solution for diverse and demanding storage needs. While specific project values and quantities are not included, these examples demonstrate the significant scale and purpose of floating roof containment solutions.

Case 1: Crude Palm Oil Processing Facility

A large-scale palm oil processing facility needed a containment solution for its crude palm oil that could maintain its quality over time. The main challenge was to prevent the oil from oxidizing when exposed to air, which would degrade its value. The project required a number of tanks, each with a substantial volume, specifically designed to protect the CPO. The solution was the deployment of floating roof tanks, which created a physical seal that effectively prevented the CPO from coming into contact with atmospheric oxygen. This was instrumental in preserving the oil's quality, ensuring it met market standards and retained its economic value.

Case 2: Refined Oil Terminal Expansion

A refined oil terminal was expanding its operations and needed new tanks that could protect its high-value refined products from contamination and evaporation. The project involved the construction of multiple tanks, each with a considerable capacity. The chosen solution was internal floating roof tanks, which provided a hermetic seal against both the atmosphere and the fixed roof. This design ensured that the refined oil remained free from airborne contaminants and that evaporation was kept to an absolute minimum, showcasing the floating roof’s ability to protect sensitive and valuable liquids in a controlled environment.

Case 3: Storage for Lubricant Products

A company specializing in lubricant production required new storage tanks that could maintain the fluid purity and stability of its products. The main concern was protecting the lubricants from external contamination and evaporation, which could compromise their performance. The project called for a series of floating roof tanks, each with a substantial volume. The floating roofs were essential in this application as they sealed the lubricants from the atmosphere, ensuring their integrity and quality over long-term storage.

A Note on Other Specialized Tanks

While floating roofs are a dominant force in the storage of atmospheric liquids, other materials, such as Liquefied Petroleum Gas (LPG), demand entirely different containment solutions. Pressure-rated tanks are a testament to this need, providing a secure method for storing gases in their liquid state under high pressure. This specialized technology is crucial for ensuring the safe containment of volatile gases, mitigating the risk of explosions and leaks. While the primary focus of this article is on the versatile applications of floating roofs, the existence of pressure-rated tanks underscores the importance of choosing the right technology for the right substance, ensuring that every storage challenge is met with a meticulously engineered solution.

Conclusion

The floating roof tank stands as a vital component of modern industrial storage, offering a sophisticated and effective solution to a range of challenges associated with volatile liquids. From the agricultural sector to the petroleum industry, its ability to minimize vapor loss, prevent oxidation, and protect product integrity has made it an indispensable technology. By providing a reliable barrier against evaporation and contamination, floating roofs not only safeguard valuable assets but also play a critical role in environmental protection and operational safety. The continued reliance on this technology for diverse and demanding applications is a testament to its enduring value and its central role in ensuring a safer, more efficient, and more responsible future for industrial storage.