-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

|

Detail Information |

|||

Product Description

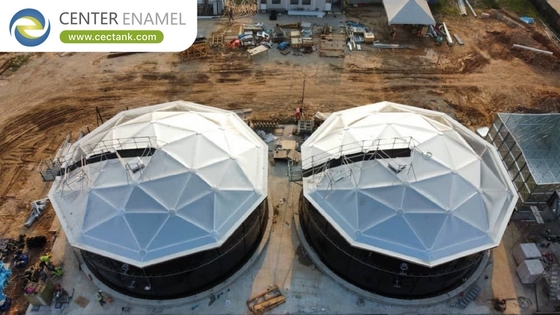

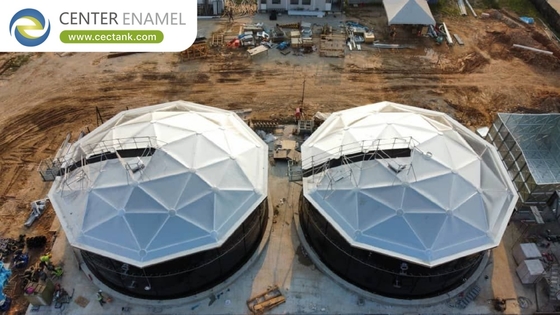

Aluminum Geodesic Dome Roofs for Gasoline Storage Tanks-Center Enamel

In the global energy landscape, Gasoline Storage Tanks represent some of the most critical and high-risk assets. Gasoline, with its inherent volatility and low flash point, demands storage solutions that prioritize safety, stringent emission control, and the prevention of product loss above all else. Traditional tank covers often fall short, leading to significant environmental hazards, economic inefficiencies from evaporation, and an elevated risk of catastrophic events. It is within this exceptionally demanding environment that Aluminum Geodesic Dome Roofs have emerged as the definitive, industry-leading solution, setting an uncompromising standard for safety, environmental compliance, and operational sustainability for Gasoline Storage Tanks.

At Shijiazhuang Zhengzhong Technology Co., Ltd, globally recognized as Center Enamel, we are not merely manufacturers; we are innovators dedicated to providing advanced storage solutions that redefine industry best practices. With decades of specialized experience in delivering robust bolted tank technologies and precision-engineered covers, we have proudly established ourselves as a premier China Aluminum Geodesic Dome Roofs Manufacturer. Our unwavering commitment to cutting-edge design, uncompromised quality, and comprehensive customer support ensures that our dome roofs provide ultimate protection, mitigating the severe risks associated with gasoline storage, enhancing environmental performance, and optimizing the operational longevity of Gasoline Storage Tanks worldwide.

The Unprecedented Risks of Gasoline Storage

Storing gasoline presents a unique set of formidable challenges due to its inherent properties and the stringent regulatory environment governing its handling:

Extreme Fire and Explosion Risk: Gasoline is highly flammable, and its vapors, when mixed with air, create an explosive atmosphere. A minimal ignition source—a spark, static discharge, lightning strike, or even inadequate ventilation—can lead to devastating fires or explosions, posing severe threats to human life, extensive infrastructure damage, and widespread environmental impact.

High VOC Emissions and Environmental Impact: Gasoline contains a significant concentration of volatile organic compounds (VOCs), including hazardous air pollutants like benzene, toluene, and xylene. These vapors readily evaporate into the atmosphere, contributing to ground-level ozone (smog), impacting air quality, and presenting health risks. Strict environmental regulations globally mandate sophisticated emission control to mitigate this pervasive issue.

Substantial Economic Losses from Evaporation: Due to its high vapor pressure, gasoline experiences significant evaporative losses when exposed to the atmosphere, even through minor leaks or inadequate seals. These continuous losses represent a direct, substantial financial drain for operators, impacting profitability and resource efficiency throughout the supply chain.

Maintaining Product Quality and Purity: Gasoline is produced to exacting specifications. Any external contamination from dust, debris, rainwater, or even atmospheric moisture can compromise product quality, leading to off-spec batches, requiring costly reprocessing, or devaluing the product.

Regulatory Scrutiny: The storage of gasoline is subject to rigorous national and international regulations (e.g., EPA standards in the US, ATEX directives in Europe, and local fire codes). Non-compliance can result in severe penalties, operational shutdowns, and significant reputational damage.

Effectively addressing these challenges demands a tank cover solution that provides an absolute barrier, not only structurally robust but also inherently safe, environmentally responsible, and economically beneficial over its entire lifespan.

Aluminum Geodesic Dome Roofs: The Ultimate Defense for Gasoline Storage

Aluminum Geodesic Dome Roofs are meticulously engineered to confront the extreme demands posed by Gasoline Storage Tanks, leveraging a unique combination of material properties and structural ingenuity to deliver unparalleled safety and performance.

Non-Sparking Properties of Aluminum: This is arguably the most critical safety advantage for gasoline storage. Aluminum is inherently non-sparking, meaning it will not generate dangerous friction sparks when struck by tools or other components. In an atmosphere laden with highly explosive gasoline vapors, this passive safety feature is indispensable, drastically reducing the risk of accidental ignition and catastrophic events.

Superior Vapor Containment (Hermetic Seal): The precision-fabricated and hermetically sealed design of an Aluminum Geodesic Dome Roof creates an exceptionally tight enclosure over the tank. This is paramount for:

Drastically minimizing VOC emissions: Significantly reducing environmental impact and ensuring compliance with stringent air quality regulations.

Preventing explosive mixtures: By containing vapors, the dome helps prevent the formation of vapor-air mixtures that could ignite, thereby enhancing overall site safety.

Minimizing Product Loss: By sealing off the tank's contents from atmospheric exposure, the dome virtually eliminates evaporative losses, preserving valuable gasoline and delivering substantial economic savings over the tank's operational life.

Corrosion Resistance and Product Integrity: Aluminum's natural formation of a passive oxide layer provides outstanding resistance to corrosion, even in aggressive chemical environments or when exposed to various gasoline additives. This ensures the long-term structural integrity of the cover, preventing material degradation that could contaminate the gasoline and compromise its quality.

Structural Robustness and External Protection (Geodesic Design): The geodesic structure, an intricate network of interconnected triangular facets, forms a self-supporting, spherical shell that is inherently strong and stable. This design allows for extraordinary resilience against extreme environmental forces such as hurricane-force winds, heavy snow loads, and seismic activity. This robust protection guards against structural failure from external impacts, which could lead to dangerous releases of gasoline.

Lightweight Design and Low Maintenance: The inherent lightness of aluminum minimizes the structural load on the tank walls and foundation, simplifying installation and often making retrofitting onto existing tanks more feasible. Once installed, the exceptional durability and corrosion resistance of these domes translate into minimal ongoing maintenance requirements, reducing the need for personnel to operate in hazardous zones and significantly lowering operational costs over decades.

Seamless Compatibility with Advanced Safety Systems: Aluminum Geodesic Dome Roofs are designed for easy and effective integration with critical safety systems vital for gasoline storage, including inert gas blanketing systems (to reduce oxygen levels), sophisticated vapor recovery units (VRUs), fire suppression systems, and various sensors for continuous monitoring.

Meeting Rigorous Standards and Maximizing Value with Center Enamel's Domes

Center Enamel's Aluminum Geodesic Dome Roofs are instrumental in elevating the safety profile, operational efficiency, and regulatory compliance of Gasoline Storage Tanks. By proactively controlling VOC emissions, our domes directly assist facilities in achieving and maintaining compliance with the most stringent environmental regulations, averting costly penalties and enhancing corporate responsibility. The significant reduction in economic losses from evaporation translates into substantial savings for operators, turning a major cost center into a source of efficiency. Furthermore, the inherent non-sparking properties of aluminum, coupled with the robust geodesic design, fundamentally reduce fire and explosion risks, creating a safer working environment. Our commitment to quality ensures these domes are engineered for long service lives, providing asset owners with a reliable, low-maintenance solution that protects their high-value gasoline products for decades. As a responsible China Gasoline Storage Tanks Manufacturer in terms of providing critical components, Center Enamel plays a vital role in ensuring the safety and efficiency of the global gasoline supply chain.

Center Enamel's Proven Capability in Critical Tank Covers

Center Enamel's extensive experience in delivering sophisticated storage solutions extends across a diverse range of critical industrial applications. The advanced engineering and reliable performance of our Aluminum Geodesic Dome Roofs are consistently demonstrated in high-stakes projects globally, illustrating our unwavering capability to meet the most rigorous standards for tank covers across various industries. This proven expertise in designing and manufacturing durable, highly protective dome solutions for large and essential storage applications directly translates to our commitment to excellence for Gasoline Storage Tanks.

In a significant Saudi Arabia Drinking Water Project, Center Enamel was entrusted with supplying Aluminum Geodesic Dome Roofs for 9 units with a substantial total capacity of 37,300 cubic meters. This showcases our ability to deliver highly specialized cover solutions for vast, critical storage infrastructure.

For a key Malaysia Drinking Water Project, we provided Aluminum Geodesic Dome Roofs for 2 units with a total capacity of 7,488 cubic meters. This highlights our precision manufacturing and reliable project execution in demanding environments.

A crucial Mexico Drinking Water Project saw Center Enamel supply an Aluminum Geodesic Dome Roof for 1 unit with a capacity of 6,064 cubic meters. This exemplifies our capability to protect large-volume tanks under diverse conditions.

We also contributed to vital water infrastructure in Panama, supplying an Aluminum Geodesic Dome Roof for 1 unit with a capacity of 2,207 cubic meters, alongside additional units for the project. Our involvement underscores our expertise in delivering robust, sealed covers for essential storage.

Further extending our global reach, an Ecuador Drinking Water Project benefited from Center Enamel's expertise, where we provided an Aluminum Geodesic Dome Roof for 1 unit with a capacity of 891 cubic meters. This demonstrates our versatility in providing high-quality dome solutions for various project scales requiring superior tank covers.

These examples highlight our proven ability to engineer and deliver large-span, durable, and precisely manufactured Aluminum Geodesic Dome Roofs for critical storage applications globally. This experience in demanding sectors provides a strong foundation for our commitment to excellence in covering Gasoline Storage Tanks.

The Center Enamel Advantage: Your Trusted Partner for Gasoline Storage Tanks

As a leading China Aluminum Geodesic Dome Roofs Manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) has built its distinguished reputation on decades of specialized expertise and an unwavering commitment to engineering excellence. Our market leadership is a direct result of continuous innovation, fostered by a dedicated R&D team comprising top-tier engineers and scientists. This ongoing investment in research and development allows us to constantly advance material science and structural design, enabling the production of Aluminum Geodesic Dome Roofs capable of covering impressive spans and meeting the most complex project requirements globally.

Quality is the fundamental principle guiding every aspect of our operations. Our manufacturing processes adhere to the most stringent international standards, with comprehensive certifications including ISO 9001 and EN1090, affirming our dedication to structural integrity and reliable performance. Every component of our Aluminum Geodesic Dome Roofs is precision-manufactured in our advanced, certified facilities, ensuring consistent quality, perfect fit, and ease of assembly on-site. Our expansive global footprint, marked by successful installations in over a hundred countries and thousands of completed projects across diverse critical applications, attests to the immense trust our clients place in our products and services worldwide.

Choosing Center Enamel means engaging with a partner that offers a comprehensive "Full Chain Service." This integrated approach covers every phase of your project, from initial engineering scheme consultation and bespoke design tailored to international standards, through automated and intelligent production processes, to efficient on-site installation performed by highly experienced teams, and sustained by rapid, global after-sales support. This holistic service model, combined with our vast experience in handling complex high-hazard industrial projects, makes us the ideal partner for any scale of Gasoline Storage Tanks covering needs, ensuring seamless execution and enduring performance.

Invest in Uncompromising Safety and Efficiency with Center Enamel

The secure, efficient, and environmentally compliant storage of gasoline is an absolute imperative for the global energy supply chain. Aluminum Geodesic Dome Roofs from Center Enamel represent the pinnacle of advanced tank cover solutions, offering unmatched benefits in fire and explosion prevention, rigorous vapor emission control, and significant reduction of product loss. They are an essential investment for ensuring the highest levels of safety, operational integrity, and environmental stewardship for Gasoline Storage Tanks.

As a trusted China Aluminum Geodesic Dome Roofs Manufacturer, Center Enamel is dedicated to providing innovative, high-quality, and reliable solutions that meet the evolving needs of the global petroleum industry. Partner with us to elevate the safety, efficiency, and longevity of your gasoline storage assets with a roofing solution engineered for decades of superior performance and peace of mind.