-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (428)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (350)

-

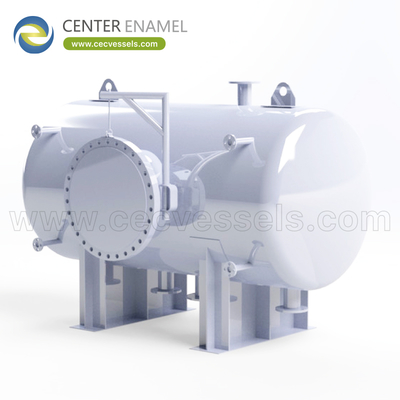

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (357)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel): China's Leading Manufacturer of Reactor Pressure Vessels

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001,CE, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001 |

| Minimum Order Quantity: | 1 Sets |

| Price: | 2000 |

| Delivery Time: | 2 months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets / days |

|

Detail Information |

|||

Product Description

| Attribute | Value |

|---|---|

| Material | Steel or stainless steel |

| Color | Customized |

| Sizes | Customized |

| Design Standards | GB150-2011 |

| Applications | Chemical, pharmaceutical, petroleum and petrochemical, new energy industries |

| Products | Tanks, Pressure Vessels, Reactors, Heat Exchangers, Towers |

As the global marketing writer for Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), I am thrilled to spotlight our leadership in the manufacturing of high-quality reactor pressure vessels. Our commitment to innovation, precision engineering, and safety has established Center Enamel as a premier partner for industries that demand the utmost in performance and reliability for their critical processes.

As a Global Leading Pressure Vessels Manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) powers global industries with unrivaled pressure vessel solutions. Your trusted global partner for mission-critical pressure vessels, Center Enamel stands at the forefront of pressure vessel innovation and manufacturing, delivering pressure vessel solutions to industries worldwide.

- Atmospheric Pressure Vessels: Horizontal Containers, Vertical Cylindrical Containers, Vertical Cylindrical Storage Tanks

- Separator Pressure Vessels: Gravity Separator, Cyclone Separator, Coalescing Separator, Centrifugal Separator, Steam-water Separator, Bearing Separator, Mechanical Filter, Ion exchange Filter, Air Filter, Fuel Filter, Adsorption Filter, BioFilter, Oil Filter, Hydraulic oil Filter, Separator

- Heat Exchangers: Shell and Tube Heat Exchangers, Plate Heat Exchangers, Spiral Heat Exchangers, Air Coolers, Liquid Coolers, Thermoelectric Coolers, Chill Water Main Unit, Evaporative Condensers, Air cooled Condensers, Electronic Gas Condensers

- Reactor Pressure Vessels: Stirred Tank Reactors, Continuous Stirred-tank Reactors, Tubular Reactors, Tower Reactors, Fixed Bed Reactors, Fluidized Bed Reactors, Bioreactors

At Center Enamel, we understand that reactor pressure vessels are the heart of many industrial operations, from chemical and pharmaceutical production to wastewater treatment and biogas generation. The integrity and performance of these vessels are non-negotiable. Our engineering team, with decades of experience, designs and manufactures reactor vessels that are not only robust but also optimized for specific process requirements.

Our state-of-the-art manufacturing facilities are equipped with cutting-edge technology, allowing us to produce vessels that meet and exceed rigorous international standards such as ASME, PED, and GB. We employ advanced welding techniques, automated production lines, and a meticulous quality assurance process to ensure every vessel is built to perfection.

A key differentiator for Center Enamel is our advanced Glass-Fused-to-Steel (GFS) technology. This proprietary process creates a permanent, monolithic bond between a specialized glass coating and the steel substrate. The result is a reactor vessel that offers unparalleled resistance to corrosion, abrasion, and chemical attack.

Our GFS reactor vessels provide a cost-effective, durable, and highly reliable alternative to traditional stainless steel or concrete vessels, particularly in environments where corrosion is a major concern.

We don't simply supply a product; we collaborate with our clients to provide a complete solution. From initial design and engineering to manufacturing, installation, and after-sales support, Center Enamel is a partner at every stage of the project.

Our commitment to client success and our reputation for quality have solidified our position as China's leading manufacturer of reactor pressure vessels. We are proud of the trust our global partners place in us and are dedicated to continuing our legacy of excellence.