-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Center Enamel: Enabling Continuous and Controlled Reactions as a Leading China Tubular Reactor Manufacturer

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001,CE, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001 |

| Minimum Order Quantity: | 1 Sets |

| Price: | 2000 |

| Delivery Time: | 2 months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets / days |

|

Detail Information |

|||

Product Description

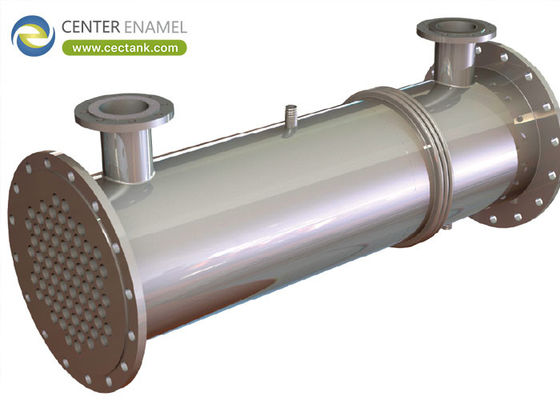

Center Enamel: Enabling Continuous and Controlled Reactions as a Leading China Tubular Reactor Manufacturer

In the landscape of modern chemical, petrochemical, and pharmaceutical processing, tubular reactors stand as a cornerstone for continuous and highly controlled chemical reactions. Their design, characterized by elongated tubes or channels, offers significant advantages for specific reaction types, including excellent heat transfer, precise residence time control, and the ability to handle high pressures and temperatures. From large-scale petrochemical synthesis and catalytic reforming to continuous pharmaceutical production and specialized chemical processing, tubular reactors play a crucial role in optimizing efficiency, selectivity, and safety. At the forefront of China's tubular reactor manufacturing industry stands Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a national "little giant" enterprise recognized for its specialization, innovation, and unwavering commitment to quality. Integrating in-house R&D, meticulous design, advanced manufacturing, and comprehensive sales, Center Enamel has firmly established itself as a leading China tubular reactor manufacturer, providing a comprehensive portfolio of robust and high-performance continuous reaction systems and unparalleled technical expertise to a diverse range of industries.

For decades, Center Enamel has been dedicated to the independent design, production, and manufacturing of a diverse range of process equipment. Recognizing the fundamental importance of tubular reactors for continuous and controlled processing, we have cultivated deep expertise in the design and fabrication of high-performance reaction systems. Our focus extends across industries including petrochemicals (cracking, reforming), chemicals (polymerization, oxidation), pharmaceuticals (continuous synthesis), energy (syngas production), and more, enabling us to engineer bespoke tubular reactor solutions that precisely address the unique and often demanding requirements of continuous chemical transformations. Guided by our core values of "quality, sincerity, friendship, progress and innovation," we actively champion development and innovation, consistently prioritizing customer needs in every facet of our operations. Our relentless pursuit of product excellence and technological advancement ensures that we continuously enhance our capabilities, empowering us to wholeheartedly deliver superior tubular reactor solutions and comprehensive support to our esteemed clientele.

Engineered for Continuous and Controlled Flow Reactions: Tailored Tubular Reactor Solutions Through Innovative Design

At Center Enamel, we recognize that effective tubular reactor design demands a comprehensive understanding of chemical reaction kinetics in continuous flow systems, heat transfer principles in confined geometries, fluid dynamics (laminar and turbulent flow), material science (corrosion resistance, high-pressure strength), and integration with continuous process lines. The diverse nature of chemical reactions, varying throughput requirements, and the properties of the reactants and products necessitate tailored solutions. In response to these varied and often demanding requirements, our design philosophy is anchored in high-standard engineering, driven by a commitment to crafting exclusive tubular reactors meticulously adapted to each customer's unique application and operating conditions. Our engineering approach meticulously considers the critical factors that govern efficient continuous reaction, precise residence time distribution, effective heat transfer to and from the reacting fluids, robust containment under high pressure and temperature, material compatibility with the process chemistry, ease of integration with upstream and downstream equipment, and accessibility for maintenance and cleaning.

During the design phase, we conduct a thorough analysis of the continuous reaction process, meticulously evaluating reaction kinetics, stoichiometry, heat of reaction, flow rates, desired conversion, and any specific requirements for temperature profiles or staged addition of reactants or catalysts along the reactor length. Our design process involves selecting the appropriate reactor material (e.g., stainless steel, carbon steel with specialized linings, high-performance alloys like Inconel or Hastelloy), tube diameter and length (optimized for residence time and heat transfer area), reactor configuration (single tube, multitubular bundle, coiled tube), and heat transfer mechanism (e.g., jacketed, immersion in a heat transfer fluid, direct firing). We carefully consider the pressure and temperature rating of the reactor, designing for safe operation under the intended process conditions, often involving high pressures. For catalytic reactions, we design for efficient catalyst loading and contact with the reactants. For highly exothermic or endothermic reactions, we focus on maximizing heat transfer efficiency to maintain precise temperature control and prevent hotspots or cold spots. Furthermore, the ease of cleaning (pigging, chemical cleaning) and maintenance are integral to our design, ensuring efficient continuous operation and minimizing downtime. This holistic design methodology guarantees that every tubular reactor leaving our facilities is engineered to deliver exceptional continuous process performance, safety, and reliability for long-term operation within integrated process lines.

Precision in Production: Crafting Excellence in Every Tubular Reactor

The safe and efficient operation of a tubular reactor, often under high pressure and temperature in continuous high-throughput processes, is inextricably linked to the precision and meticulousness employed during its manufacturing. At Center Enamel's advanced production workshop, we utilize specialized equipment for the precise cutting, bending, and welding of tubes from various high-strength and corrosion-resistant materials. Our skilled welders, certified to international standards, execute welds with precision to ensure pressure containment and structural integrity under demanding operating conditions. For reactors requiring specialized linings, we employ advanced techniques for applying and testing these linings to achieve excellent corrosion resistance within the tubular geometry. The fabrication and assembly of multitubular bundles, coiled tubes, and associated headers and manifolds require meticulous alignment and securement to ensure uniform flow distribution and pressure integrity. The integration of inlet and outlet connections, as well as instrumentation ports, is carried out with precision to ensure seamless connection to continuous process lines. Complementing this advanced machinery and highly skilled workforce is our comprehensive suite of professional testing equipment, which plays an integral role in our stringent quality control processes. This unwavering commitment to precision manufacturing guarantees that our tubular reactor products consistently meet the high standards demanded by our diverse clientele in continuous processing industries.

Unwavering Quality Assurance: Ensuring Optimal Continuous Process Performance and Safety

Our dedication to quality extends throughout the entire lifecycle of our tubular reactors, culminating in a rigorous and comprehensive testing system. This system is designed to guarantee that the performance, safety, and material integrity of our products not only meet but consistently exceed stringent domestic and international standards for pressure vessels and continuous process equipment. Our multi-layered testing regime includes:

Material Verification: We conduct thorough material verification tests to ensure that the reactor tubes and other components are fabricated from the specified materials with the correct chemical composition, mechanical properties (including high-temperature strength and creep resistance), and corrosion resistance.

Welding Inspection: Our skilled welding is subjected to rigorous inspection, including visual examination and Non-Destructive Testing (NDT) such as radiographic, ultrasonic, or magnetic particle testing, to ensure the integrity and strength of all welded joints, critical for pressure containment under high operating pressures and temperatures.

Hydrostatic Testing: Each tubular reactor undergoes rigorous hydrostatic testing at pressures significantly higher than the design operating pressure to verify its structural integrity and leak tightness throughout the entire tubular network and associated connections.

Flow Distribution Testing (for multitubular reactors): We may conduct flow distribution tests to ensure uniform flow of reactants through all the tubes in a multitubular bundle, which is crucial for consistent reaction conditions and product quality.

Heat Transfer Testing (Optional): Depending on the design, we may conduct heat transfer tests to verify the efficiency of the heating or cooling system associated with the tubular reactor.

Lining Integrity Testing (for lined reactors): For reactors with specialized linings, we perform rigorous testing to ensure the integrity and continuity of the lining within the tubes and headers, detecting any potential defects.

Dimensional Inspection: Thorough dimensional inspections are carried out at various stages of manufacturing to ensure that all components meet the specified tolerances and dimensions for proper assembly and integration into continuous process lines.

Final Inspection: A comprehensive final inspection is performed to ensure the overall quality, finish, and completeness of the tubular reactor.

The Cornerstones of Our Tubular Reactor Manufacturing Expertise:

Our leadership in the China tubular reactor manufacturer landscape is built upon a robust manufacturing process characterized by several key strengths:

Expertise in High-Pressure Vessel Fabrication: We possess deep expertise in the fabrication of pressure vessels, including advanced welding techniques and quality control procedures for ensuring safe operation under high pressures and temperatures.

Advanced Material Science and Fabrication for Demanding Conditions: We have extensive experience working with a wide range of high-performance materials, including specialized alloys and linings, to ensure compatibility with aggressive chemicals and extreme operating conditions.

Precision Tube Bending and Welding for Complex Geometries: We have specialized capabilities for the precise bending and welding of tubes in various configurations (single tube, coils, multitubular bundles) while maintaining pressure integrity and flow characteristics.

Comprehensive Understanding of Continuous Flow Reaction Engineering: Our engineering team has a strong understanding of the principles governing continuous reactions, residence time distribution, and heat transfer in tubular reactors.

Seamless Integration with Continuous Process Lines: Our designs focus on ensuring smooth and reliable integration of tubular reactors with upstream and downstream equipment in continuous processing facilities.

Stringent Quality Control for High-Performance Reactors: Our comprehensive quality control system and thorough testing procedures are adapted for the unique challenges of manufacturing and testing reactors operating under demanding continuous flow conditions.

Serving Diverse Industries with Reliable and Efficient Tubular Reactor Solutions:

Center Enamel's expertise as a leading China tubular reactor manufacturer allows us to provide critical continuous processing equipment across a wide array of industries:

Petrochemicals: Our tubular reactors are used for catalytic cracking, catalytic reforming, isomerization, and other continuous petrochemical processes operating at high temperatures and pressures.

Chemicals: We provide tubular reactors for continuous polymerization reactions (e.g., LDPE), oxidation reactions, and other continuous chemical syntheses.

Pharmaceuticals: Our reactors are used for continuous flow synthesis of active pharmaceutical ingredients (APIs) and intermediates, offering precise control and scalability.

Energy: Tubular reactors are used in syngas production via steam reforming and other continuous energy conversion processes.

Food Processing: Continuous pasteurization and sterilization processes can utilize tubular heat exchangers functioning as reactors.

Environmental: Tubular reactors can be used for continuous treatment of hazardous wastes and other environmental applications.

A Comprehensive Portfolio of Tubular Reactor Designs:

Center Enamel possesses the expertise and capabilities to manufacture various types of tubular reactors, including:

Single Tube Reactors: Simple designs for smaller scale continuous processing or research applications.

Multitubular Reactors: Featuring a bundle of parallel tubes within a shell, offering a large heat transfer area for reactions with significant heat exchange requirements.

Coiled Tube Reactors: Utilizing coiled tubes to increase residence time in a compact footprint and enhance heat transfer.

Plug Flow Reactors (PFRs): Designed to minimize axial mixing, approximating ideal plug flow for predictable reaction times.

Fixed Bed Reactors: Tubular reactors packed with solid catalyst for heterogeneous catalytic reactions.

Catalytic Wall Reactors: Reactors where the catalyst is coated on the inner walls of the tubes.

Center Enamel – Your Premier Partner for Leading Tubular Reactor Solutions in China

As a national "little giant" enterprise, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) stands as a leading China tubular reactor manufacturer, driven by a profound commitment to specialization, innovation, and uncompromising quality. Our comprehensive capabilities, encompassing meticulous design tailored for continuous and controlled flow reactions, advanced manufacturing techniques for robust construction under demanding conditions, rigorous testing adapted for continuous processing systems, and a deep understanding of the unique requirements of various industrial applications, ensure that we can effectively address the most challenging continuous reaction equipment needs. By choosing Center Enamel, you are partnering with a company dedicated to providing high-performance, safe, and reliable tubular reactor solutions, backed by decades of engineering expertise and an unwavering commitment to customer success in continuous processing industries. We are proud to be at the forefront of China's continuous reaction technology, empowering our clients with the critical infrastructure they need for efficient and controlled chemical transformations.