-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

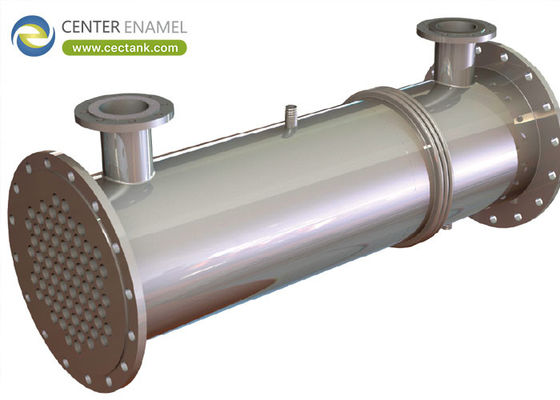

Center Enamel: Pioneering Separation Solutions as a Leading China Separation Pressure Vessel Manufacturer

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001,CE, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001 |

| Minimum Order Quantity: | 1 Sets |

| Price: | 2000 |

| Delivery Time: | 2 months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets / days |

|

Detail Information |

|||

Product Description

Center Enamel: Pioneering Separation Solutions as a Leading China Separation Pressure Vessel Manufacturer

In the intricate world of industrial processing, the efficient and reliable separation of diverse components is paramount. Across sectors ranging from the complex refineries of petrochemicals to the stringent purity demands of biopharmaceuticals, and the delicate processing of food and beverage, separation pressure vessels stand as indispensable workhorses. At the forefront of China's separation pressure vessel manufacturing industry stands Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a national "little giant" enterprise distinguished by its specialization, innovation, and unwavering commitment to quality. Integrating in-house R&D, meticulous design, advanced manufacturing, and comprehensive sales, Center Enamel has firmly established itself as a leading China separation pressure vessel manufacturer, providing a comprehensive portfolio of separation solutions and unparalleled technical expertise to a wide spectrum of industries.

For decades, Center Enamel has been dedicated to the independent design, production, and manufacturing of a diverse range of separation pressure vessel equipment. Our deep-rooted expertise extends across numerous sectors, including petrochemicals, biopharmaceuticals, food and beverage, and environmental protection, enabling us to engineer bespoke solutions that precisely address the unique and often complex separation challenges within each. Guided by our core values of "quality, sincerity, friendship, progress and innovation," we actively champion development and innovation, consistently prioritizing customer needs in every facet of our operations. Our relentless pursuit of product excellence and technological advancement ensures that we continuously enhance our capabilities, empowering us to wholeheartedly deliver superior separation solutions and comprehensive support to our esteemed clientele.

Engineered for Precision: Tailored Separation Solutions Through Innovative Design

At Center Enamel, we recognize that effective separation is rarely a one-size-fits-all endeavor. The diverse nature of industrial mixtures and the specific requirements of downstream processes necessitate tailored solutions. In response to the varied and often intricate demands of separation under pressure, our design philosophy is anchored in high-standard engineering, driven by a commitment to crafting exclusive separation pressure vessels meticulously adapted to each customer's unique application and operating conditions. Our engineering approach meticulously considers the critical factors that govern efficient separation, optimal performance, and uncompromising safety.

During the design phase, we conduct a thorough analysis of the mixture to be separated, meticulously evaluating its constituent phases (liquid, gas, solid), their physical properties (density, volatility, solubility), and any potential for complex interactions. Temperature and pressure are paramount considerations, directly influencing the vessel's structural integrity and the efficiency of the separation process. Furthermore, the chemical characteristics of the media involved, particularly their acid or alkaline properties, are a key determinant in our rigorous material selection process, ensuring compatibility and preventing corrosion. This holistic design methodology guarantees that every separation pressure vessel leaving our facilities is engineered to deliver exceptional performance, unwavering safety, and long-term reliability, even when operating under the most demanding and intricate separation scenarios.

Precision in Production: Crafting Excellence in Every Separation Vessel

The effectiveness of a separation pressure vessel is inextricably linked to the precision and meticulousness employed during its manufacturing. At Center Enamel's advanced production workshop, we harness the power of automated CNC equipment for the precise cutting and forming of vessel components. This cutting-edge technology ensures unparalleled accuracy and consistency in every stage of production, critical for the intricate internal configurations often required for efficient separation. Complementing this advanced machinery is our comprehensive suite of professional testing equipment, which plays an integral role in our stringent quality control processes. This unwavering commitment to precision manufacturing guarantees that our separation pressure vessel products consistently meet the high standards demanded by our diverse clientele across a multitude of industries.

Unwavering Quality Assurance: Ensuring Optimal Separation Performance and Safety

Our dedication to quality extends throughout the entire lifecycle of our separation pressure vessels, culminating in a rigorous and comprehensive testing system. This system is designed to guarantee that the performance and safety of our products not only meet but consistently exceed stringent domestic and international standards. Our multi-layered testing regime includes:

Nondestructive Testing (NDT): We employ advanced nondestructive testing methodologies to meticulously examine the integrity of welded joints, a critical aspect of ensuring the pressure containment and long-term reliability of our separation vessels. For butt-welded joints, local radiographic or ultrasonic testing is conducted, covering a minimum of 10% of the length of each weld. Crucially, local NDT also encompasses T-joints and other critical intersections, ensuring the structural soundness of the entire vessel. All nondestructive testing of welded joints is carried out in strict accordance with JB4730.2 and JB4730.3 standards. For radiographic testing, we adhere to a technical level of AB with a quality level not lower than Sichuan level. Our ultrasonic testing follows a technical level of B with a quality level not lower than Level II.

Final Testing Procedures: Following the manufacturing process, each separation pressure vessel undergoes rigorous final testing tailored to its specific application and design requirements. This includes comprehensive water, hydraulic pressure, air pressure, air tightness, or kerosene leakage tests, as mandated by the engineering drawings. These tests serve as a final verification of the vessel's structural integrity and its ability to safely and effectively perform its intended separation functions under pressure.

The Cornerstones of Our Separation Vessel Manufacturing Expertise:

Our leadership in the China separation pressure vessel manufacturer landscape is built upon a robust manufacturing process characterized by several key strengths:

Strategic Material Selection: The foundation of a high-performing and durable separation pressure vessel lies in the quality of its materials. At Center Enamel, we exclusively source steel from reputable, large-scale domestic steel mills, ensuring that the strength, toughness, and hardness of our materials consistently exceed industry benchmarks. This commitment to superior materials directly translates into enhanced durability and a prolonged operational lifespan for our separation solutions.

Advanced Welding Proficiency: Our welding processes integrate cutting-edge equipment and refined techniques, executed by a team of highly skilled and certified professionals. This synergy of technology and expertise results in efficient production, smooth and uniform welds with precise lines, and ultimately guarantees the structural integrity and optimal performance of our separation vessels under pressure.

Customized Coating Solutions: Recognizing the diverse chemical environments encountered in separation processes, our spraying process is meticulously tailored to meet specific customer needs and adhere to stringent industry standards. By applying appropriate anti-rust and corrosion-resistant coatings, we significantly enhance the durability and extend the service life of our separation vessels, ensuring reliable operation even with aggressive media.

Precision Surface Preparation: Proper surface preparation is crucial for the longevity and effectiveness of protective coatings. Our large-scale sandblasting equipment and advanced sandblasting process ensure that the surface of each vessel is uniformly flat and optimally prepared for subsequent treatments. This meticulous preparation also contributes to a high-quality finish.

Rigorous Performance Testing: As previously detailed, our professional testing equipment conducts stringent sealing and pressure tests on every separation pressure vessel before it leaves our facility. This final stage of verification is paramount in ensuring the safety and the effective performance of the intended separation process under the specified operating conditions.

Serving Diverse Industries with Tailored Separation Solutions:

Center Enamel's expertise as a leading China separation pressure vessel manufacturer allows us to provide critical separation solutions across a wide array of industries:

Petrochemicals: Our separation pressure vessels are integral to various refining and processing stages. They are used to separate crude oil, natural gas, and water at different stages of production, from initial wellhead separation to processing at refineries. Our designs cater to two-phase (liquid-gas), three-phase (oil-water-gas), and specialized separation requirements.

Biopharmaceuticals: In this sector demanding high purity, our separation pressure vessels are crucial for isolating desired products from reaction mixtures, removing byproducts, and purifying feedstocks. Applications range from separating immiscible liquids to removing solid catalysts from liquid streams, ensuring the quality and safety of pharmaceutical products.

Food and Beverage: Our separation pressure vessels play a vital role in processes such as separating cream from milk, clarifying juices, and removing solids from liquid food products. Hygienic design and materials are paramount in these applications, ensuring the quality and safety of consumable goods.

Environmental Protection: Our separation pressure vessels are utilized in water treatment facilities to remove suspended solids, oil, and other contaminants from water sources. They are also employed in industrial processes for separating pollutants from liquid or gaseous streams, contributing to environmental sustainability.

Center Enamel – Your Premier Partner for Separation Pressure Vessel Solutions in China

As a national "little giant" enterprise, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) stands as a leading China separation pressure vessel manufacturer, driven by a profound commitment to specialization, innovation, and uncompromising quality. Our comprehensive capabilities, encompassing meticulous design, advanced manufacturing, rigorous testing, and tailored solutions, ensure that our separation pressure vessels effectively address the diverse and complex separation challenges faced by industries across China. By choosing Center Enamel, you are partnering with a company dedicated to providing high-performance, safe, and reliable separation solutions, backed by decades of engineering expertise and an unwavering commitment to customer success. We are proud to be at the forefront of China's separation technology, empowering our clients with the critical infrastructure they need to achieve efficient and effective separation in their vital industrial processes.