-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Enhancing Filtration Efficiency and Product Quality: Center Enamel's Pressure Filtration Vessels

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001,CE, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001 |

| Minimum Order Quantity: | 1 Sets |

| Price: | 2000 |

| Delivery Time: | 2 months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets / days |

|

Detail Information |

|||

Product Description

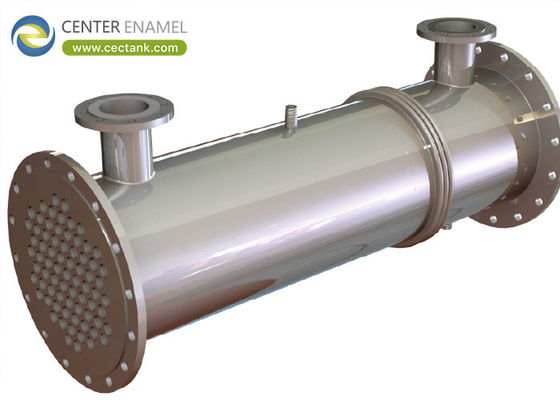

Enhancing Filtration Efficiency and Product Quality: Center Enamel's Pressure Filtration Vessels

In numerous industrial processes across the chemical, pharmaceutical, food and beverage, and water treatment sectors, the removal of solid particles from liquid streams is crucial for achieving product quality, ensuring process efficiency, and meeting regulatory standards. Pressure Filtration Vessels are essential components in these operations, providing a reliable and effective means of solid-liquid separation. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a globally recognized leader in the design and manufacturing of high-quality storage and process vessels, offers advanced Pressure Filtration Vessels engineered for exceptional performance, reliability, and safety in diverse and demanding industrial applications worldwide.

Building upon a strong foundation as a premier China Storage Tanks Manufacturer, Center Enamel has established a reputation for quality and innovation across a wide range of vessel technologies, including Glass-Fused-to-Steel (GFS) tanks and other specialized solutions. This extensive experience in material science, engineering, and a deep understanding of fluid handling and processing has naturally positioned them as a trusted provider of Pressure Filtration Vessels. Their commitment to adhering to international standards such as ISO9001, ASME, CE/EN1090, and other relevant pressure vessel codes ensures that their Pressure Filtration Vessels meet the highest benchmarks of quality and safety demanded by industries globally.

Understanding the Function and Importance of Pressure Filtration Vessels:

Pressure Filtration Vessels are specialized vessels designed to separate solid particles from a liquid by forcing the liquid through a filter medium under pressure. The filter medium, which can be composed of various materials such as filter paper, filter cloth, or a bed of granular material, retains the solid particles while allowing the filtrate (the clarified liquid) to pass through. The driving force of the separation is the pressure differential across the filter medium, which is typically generated by a pump or compressed gas.

The efficient operation of Pressure Filtration Vessels is crucial for several reasons:

Product Quality: Ensures the clarity and purity of the final product by removing suspended solids and particulate matter.

Process Efficiency: Improves the performance of downstream processing units by reducing fouling, clogging, and other problems caused by solid particles.

Waste Reduction: Facilitates the recovery of valuable solids or the removal of harmful contaminants from wastewater, reducing waste disposal costs and environmental impact.

Regulatory Compliance: Helps industries meet stringent regulatory requirements for product purity and environmental discharge limits.

Equipment Protection: Protects downstream equipment, such as pumps, heat exchangers, and reactors, from damage caused by solid particles.

Center Enamel: Engineering Excellence in Pressure Filtration Vessel Solutions:

As a leading provider of Pressure Filtration Vessels, Center Enamel leverages its extensive expertise in vessel design, materials engineering, and fabrication to deliver high-performance solutions tailored to the specific needs of diverse industrial applications. Their focus is on providing durable, safe, and efficient filtration solutions that optimize process performance and ensure long-term reliability.

Key Features and Advantages of Center Enamel's Pressure Filtration Vessels:

Robust Design and Construction: Center Enamel's Pressure Filtration Vessels are designed and constructed to withstand high pressures, temperatures, and corrosive environments. We utilize high-quality steel and employ advanced welding and fabrication techniques to ensure structural integrity and longevity.

Customized Solutions: Recognizing the unique requirements of different filtration processes, Center Enamel offers customized design and engineering services to tailor Pressure Filtration Vessel solutions to specific flow rates, operating conditions, particle size distributions, and filtration objectives.

Versatile Filter Media Compatibility: Center Enamel's Pressure Filtration Vessels are designed to accommodate a wide range of filter media, including filter paper, filter cloth, filter bags, cartridges, and various types of granular media, providing flexibility for different filtration applications.

Efficient Filtration Mechanisms: Center Enamel integrates various efficient filtration mechanisms into their vessels, including surface filtration and depth filtration, to achieve optimal separation performance.

Optimized Flow Distribution: The design of internal components, such as distributors and baffles, is crucial for ensuring uniform flow distribution through the filter medium, preventing channeling and maximizing filtration efficiency. Center Enamel employs computational fluid dynamics (CFD) and other advanced engineering tools to optimize the design of these internals.

Comprehensive Material Selection: Center Enamel offers a wide range of material options for their Pressure Filtration Vessels, including carbon steel, stainless steel, and special alloys, to ensure compatibility with the specific fluids being processed and the operating environment, including potential corrosive elements.

Advanced Welding and Fabrication: Center Enamel employs certified welders and utilizes advanced welding techniques to ensure high-quality welds that meet stringent industry standards and pressure vessel codes, such as ASME.

Stringent Quality Control: Center Enamel implements rigorous quality control procedures throughout the entire manufacturing process, from material inspection to final testing, to ensure that their Pressure Filtration Vessels meet the highest standards of quality, safety, and performance.

Compliance with International Standards: Center Enamel's Pressure Filtration Vessels are designed and manufactured to comply with relevant international pressure vessel codes and standards, such as ASME, ensuring safety and regulatory compliance in various regions.

Comprehensive Accessory Integration: Center Enamel provides a complete range of accessories for their Pressure Filtration Vessels, including pressure gauges, flow meters, valves, sampling ports, and cleaning systems, ensuring safe and efficient operation and integration into the overall process system.

Diverse Applications of Center Enamel's Pressure Filtration Vessels:

Center Enamel's high-performance Pressure Filtration Vessels are essential components in a wide range of industrial processes worldwide, including:

Chemical Processing: Removing solid catalysts, byproducts, or impurities from chemical solutions.

Pharmaceutical Manufacturing: Clarifying drug solutions, removing active carbon, and sterilizing final products.

Food and Beverage Industry: Filtering fruit juices, beer, wine, and edible oils.

Water Treatment: Removing suspended solids from drinking water, wastewater, and industrial process water.

Oil and Gas Industry: Filtering produced water, injection water, and lubricating oils.

Pulp and Paper Industry: Removing fibers and other solids from process liquors.

Center Enamel: Your Trusted Partner for Filtration Solutions:

As a leading provider of Pressure Filtration Vessels with a long-standing commitment to quality, innovation, and customer satisfaction, Center Enamel offers more than just vessels; they provide comprehensive solutions that address the critical challenges of solid-liquid separation in diverse industrial applications. Their expertise in vessel design, materials engineering, and fabrication ensures that their Pressure Filtration Vessels deliver optimal performance, enhance process efficiency, and ensure the quality and safety of operations globally.

By choosing Center Enamel for your Pressure Filtration Vessel needs, you benefit from:

Proven Expertise: Decades of experience in designing and manufacturing pressure vessels.

High-Quality Materials and Construction: Ensuring durability and reliability in demanding environments.

Customized Solutions: Vessels tailored to your specific filtration requirements.

Advanced Filtration Technology: Optimizing filtration efficiency and product quality.

Compliance with International Standards: Ensuring safety and regulatory compliance.

Comprehensive Support: Reliable service and support for projects worldwide.

In conclusion, Center Enamel stands as a premier provider of Pressure Filtration Vessels, delivering essential equipment for efficient and safe solid-liquid separation across a wide range of industries. Their commitment to quality, customization, and technological advancement ensures that their Pressure Filtration Vessels meet the evolving needs of the global industrial landscape.

Contact Center Enamel today to discuss your specific Pressure Filtration Vessel requirements and discover how our expertise can enhance your filtration processes.