-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (421)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (947)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

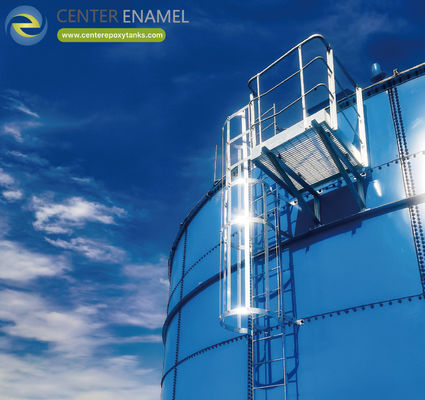

Slurry Storage Bolted Steel Water Storage Tanks Durable And Corrosion-Resistant

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008 , AWWA D103 , OSHA , BSCI |

| Model Number: | J2016012306 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008 , AWWA D103 , OSHA , BSCI | Model Number | J2016012306 |

| Acid And Alkalinity Proof: | Standard Coating Suits For PH3 - PH11, Special Coating Suits For PH1 - PH14 | Usage: | Waste Water Treatment , Sewage Treatment , Effluent Treatment Ect. |

| Corrosion Resistance: | Excellent ! Suitable For Waste Water Salt Water, Sea Water, High Sulfur Crude Oil, Salt Fox, Organic And Inorganic Compounds | Spark Test: | >1500 V |

| Service Life: | Over 30 Years | Capactiy Available: | 20 M3 To 18,000 M3 |

| PH Range: | A Grade Sheet PH:3-11, AA Grade Sheet PH : 1-14 | Highlight: | Slurry Storage Fusion Bonded Epoxy Tanks,Fusion Bolted Steel Water Storage Tanks,Corrosion-Resistant Fusion Bonded Epoxy Tanks |

Product Description

- Superior Corrosion Resistance: The FBE coating offers up to 10 times more corrosion resistance compared to traditional coatings, significantly extending the lifespan of the tank.

- High Durability and Longevity: Engineered to last, FBE tanks can operate efficiently for over 20 years with minimal maintenance.

- Resistance to Abrasion and Mechanical Damage: The tough epoxy coating resists wear and tear from abrasive slurry materials, maintaining the tank's integrity over time.

- Low Maintenance Requirements: FBE tanks require less frequent maintenance compared to traditional storage solutions, reducing downtime and maintenance costs.

Properties of Fusion Bonded Epoxy Tanks:

| Application | Test Standard | Result |

| Coating Color | Standard RAL 5015 sky blue | Other colors are available |

| Dry Film Thickness | Average Dry Thickness | 5~10 miles /125 ~250 microns(internal) |

| 5~10 miles /125 ~250 microns(epoxy primer+ topcoat) | ||

| Holiday Test | ≥1100V (all panels) | Zero-discontinuity at test voltage |

| Hot water immersion 90 days, 70° | AWWA C550-05 | Meets/exceeds standard |

| Corrosion Resistance | Salt Spray ISO 9227/ASTM B117 | Pass |

| Impact Resistance | ASTM D2794 | Pass 160 in-ibs direct & reverse impact |

| PH Range | 3~12 | |

| Abrasion Resistance | Adhesion ASTM D3359 | Adhesion ASTM D3359 |

| Hardness | ISO15184 / ASTM D3363 | 2H |

| Chemical Immersion test | 50% NaOH, 50% H2S04 | Meets/exceeds industry standard |

| UV Resistance | outdoor exposure testing | 5 years |

| Color Stability | outdoor exposure testing | 5 years |

Design and Construction of FBE Slurry Storage Tanks

- Material Selection and Coating Process: High-quality steel is used as the base material, which is then coated with fusion bonded epoxy through an advanced process that ensures uniform coverage and adhesion.

- Tank Configurations: FBE tanks can be manufactured in various configurations, including bolted and welded designs, to accommodate different storage capacities and installation environments.

- Customization Options: Tanks can be customized based on the type of slurry being stored, with features such as reinforced coatings and specialized fittings to enhance performance.

Environmental and Safety Benefits

- Environmental Protection: The robust epoxy coating prevents leaks and contamination, protecting the surrounding environment and reducing the risk of soil and water pollution.

- Regulatory Compliance: Our FBE tanks comply with ASTM D4227 and ISO 12944 standards, ensuring businesses remain compliant with environmental laws and guidelines.

- Enhanced Safety Features: The durability and integrity of FBE tanks contribute to safer storage conditions, minimizing the risk of tank failure and associated hazards.