-

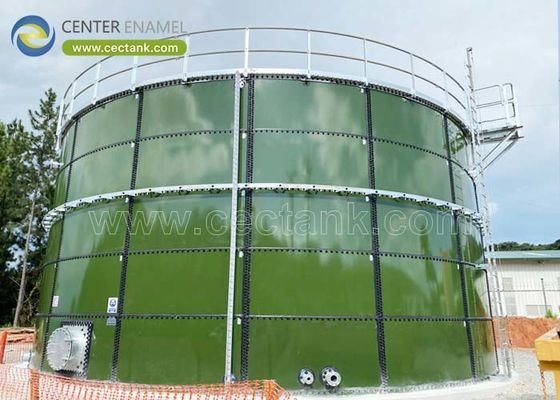

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (410)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (872)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

Optimizing Operations With Slurry Storage Tanks A Comprehensive Guide

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Optimizing Operations with Slurry Storage Tanks: A Comprehensive Guide

Slurry storage tanks play a vital role in various industries, providing efficient storage solutions for slurry, a mixture of water and solids used in processes such as mining, agriculture, and wastewater treatment. In this comprehensive guide, we explore the functionalities of slurry storage tanks, their benefits, key considerations in design, and how they optimize operations across different sectors.

Slurry Storage Tanks Introduction

Slurry storage tanks are specialized containers designed to store and manage slurry, a suspension of solids in water or other liquids. The slurry composition can vary widely, from mineral slurries in mining operations to agricultural slurries containing manure or organic matter. These tanks are engineered to handle the specific characteristics of slurry, including viscosity, solids content, and potential abrasiveness.

Benefits of Slurry Storage Tanks

Efficient Storage: Slurry storage tanks provide efficient storage capacity for slurry, allowing for continuous operations without interruptions due to storage constraints.

Process Optimization: By centralizing slurry storage, these tanks streamline processes, improve workflow efficiency, and facilitate easy access for transportation and distribution.

Environmental Protection: Proper containment of slurry in storage tanks prevents spills, leaks, and contamination of soil and water bodies, ensuring environmental compliance and sustainability.

Resource Utilization: Slurry storage tanks enable the efficient utilization of resources, such as water, minerals, and organic matter, supporting sustainable practices in industries like mining and agriculture.

Key Considerations in Slurry Storage Tank Design

Designing effective slurry storage tanks requires attention to several critical factors:

Tank Material: Selecting durable and corrosion-resistant materials, such as stainless steel, concrete, or coated steel, ensures long-term performance and protection against chemical reactions.

Tank Size and Configuration: Tank sizing should consider the volume of slurry to be stored, the frequency of replenishment, and future expansion needs. Customized configurations, including agitators and baffles, optimize slurry mixing and homogeneity.

Safety Features: Slurry storage tanks should incorporate safety features such as overflow protection, leak detection systems, and access platforms to ensure safe operations and compliance with regulatory standards.

Maintenance and Cleaning: Regular maintenance, cleaning, and inspection of slurry storage tanks are essential to prevent sedimentation, buildup of solids, and potential equipment issues, maintaining optimal performance and longevity.

Environmental Impact: Design considerations should include measures to minimize environmental impact, such as containment systems for spills, runoff management, and adherence to environmental regulations.

Slurry Storage Tanks Across Industries

Mining and Mineral Processing: Slurry storage tanks are integral to mining operations, storing mineral slurries for processing, transportation, and disposal, optimizing resource utilization and environmental management.

Agriculture and Farming: In agricultural settings, slurry storage tanks manage animal manure slurries, organic waste, and nutrient-rich liquids, supporting sustainable practices, soil fertility, and crop productivity.

Wastewater Treatment: Slurry storage tanks play a role in wastewater treatment plants, storing sludge and biosolids for dewatering, processing, and disposal, contributing to effective wastewater management and environmental protection.

Enhancing Efficiency with Slurry Storage Tanks

Slurry storage tanks are indispensable assets in industries reliant on slurry processes, offering efficient storage, process optimization, and environmental protection benefits. By leveraging well-designed and maintained slurry storage tanks, industries can optimize operations, minimize environmental impact, and achieve sustainable resource management goals, driving progress towards a more efficient and responsible future.

As a leading bolted steel tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

| Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Biogas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

Extensive Experience: With over 30 years of experience in Enameling Technology R&D, Shijiazhuang Zhengzhong Technology Co., Ltd has established itself as a leader in the industry. This extensive experience ensures a deep understanding of the nuances of tank manufacturing and enameling processes.

Comprehensive Product Range: The company offers a diverse range of products, including Glass-Fused-to-Steel tanks, fusion-bonded epoxy tanks, stainless steel tanks, galvanized steel tanks, and aluminum geodesic dome roofs. This variety allows customers to choose the most suitable option for their specific needs.

High-Quality Standards: Shijiazhuang Zhengzhong Technology Co., Ltd adheres strictly to international standards such as AWWA D103-09, OSHA, NSF/ANSI 61, EN28765, and NFPA. This commitment to quality ensures that their products meet or exceed industry requirements and regulations.

Global Acceptance: The company's GFS tanks have gained acceptance in over 90 countries worldwide, including the USA, Australia, Canada, Malaysia, Indonesia, Russia, UAE, Panama, Brazil, and South Africa. This demonstrates their ability to meet the diverse needs of international markets.

Certifications: Their products are certified to ISO 9001, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001, and other international standards. These certifications underscore their dedication to quality, safety, and environmental responsibility.

Collaborations with Industry Leaders: Shijiazhuang Zhengzhong Technology Co., Ltd has collaborated with well-known international corporations such as Paques, Veolia, Coca-Cola, Sabesp, Wilmar, PetroChina, Heineken, AbInBev, Porsche, and Sinopec. This further validates their reputation and expertise in the industry.

Customer Focus: The company emphasizes long-term cooperation with local partners worldwide, demonstrating a commitment to building lasting relationships and providing ongoing support to customers.