-

Glass Fused To Steel Tanks (419)

-

Stainless Steel Tanks (410)

-

Fusion Bonded Epoxy Tanks (424)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (872)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (297)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (181)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

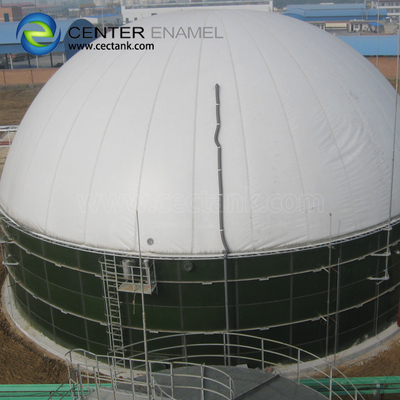

Dark Green 3mm Steel Plates Biogas Storage Tank anti adhesion

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden |

| Delivery Time: | 10-30 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W |

| Tank Body Color: | Dark Green / Can Be Customized | Corrosion Integrity: | Excellent |

| Steel Plates Thickness: | 3mm To 12mm , Depends On The Tank Structure | Chemical Resistance: | Excellent |

| Size Of Panel: | 2.4M * 1.2M | Easy To Clean: | Smooth, Glossy, Inert, Anti-adhesion |

| Highlight: | 3mm Steel Plates Biogas Storage Tank,Anti Adhesion Biogas Storage Tank,Dark Green Biogas Storage Tank |

||

Product Description

Center Enamel: The Leading Biogas Tank Manufacturer in China

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are proud to stand as the leading biogas tank manufacturer in China, with over 30 years of expertise in designing and fabricating high-quality, durable, and innovative biogas storage solutions. As the global demand for renewable energy and sustainable waste management continues to grow, we are committed to providing cutting-edge biogas tanks that empower industries, farms, and communities to harness the power of biogas for a cleaner, greener future.

As a leading storage tank manufacturer worldwide. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks Welded Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Bio gas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

A Legacy of Innovation and Excellence

Since our establishment in 1989, Center Enamel has been at the forefront of the bolted storage tank industry, pioneering the production of Glass-Fused-to-Steel (GFS) tanks in China. With a dedicated R&D team and over 100 patents, we have consistently pushed the boundaries of technology to deliver biogas tanks that meet the highest international standards.

Our biogas tanks are engineered to provide optimal performance, durability, and safety, making them the preferred choice for customers worldwide. From agricultural biogas projects to municipal wastewater treatment, our tanks are designed to handle the most demanding applications with ease.

Why Choose Center Enamel Biogas Tanks?

Superior Durability:

Our biogas tanks are constructed using Glass-Fused-to-Steel (GFS) technology, which combines the strength of steel with the corrosion resistance of glass. This ensures a service life of 30 years or more, even in harsh environments.

Gas-Tight Design:

Meticulously sealed to prevent gas leakage, our tanks ensure maximum biogas storage efficiency and safety.

Customizable Solutions:

We offer biogas tanks in various sizes and configurations to meet the specific needs of different projects, from small-scale farms to large industrial plants.

Advanced Monitoring Systems:

Equipped with state-of-the-art monitoring tools, our tanks allow for real-time tracking of temperature, pressure, and gas composition, ensuring precise control of the anaerobic digestion process.

Global Compliance:

Our biogas tanks are certified to ISO 9001, CE/EN 1090, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001, and other international standards, making them widely accepted in markets worldwide.

Applications of Our Biogas Tanks

Our biogas tanks are versatile and can be used in a wide range of applications, including:

Agricultural Biogas Projects: Transforming cow manure, crop residues, and other farm waste into renewable energy.

Food Waste Biogas Projects: Converting food waste from households, restaurants, and industries into clean energy.

Municipal Wastewater Treatment: Harnessing biogas from sewage sludge to power treatment plants and reduce operational costs.

Landfill Gas Recovery: Capturing methane emissions from landfills and converting them into usable energy.

Global Reach and Recognition

With a proven track record of success, Center Enamel has exported biogas tanks to over 100 countries, including the USA, Australia, Canada, Malaysia, Indonesia, Russia, UAE, Panama, Brazil, and South Africa. Our superior product quality and prompt service have earned us worldwide recognition and the trust of leading international corporations such as Paques, Veolia, Coca-Cola, Sabesp, Wilmar, PetroChina, Heineken, AbInBev, Porsche, and Sinopec.

Why Center Enamel Stands Out

30+ Years of Expertise:

With decades of experience in enameling technology R&D, we bring unparalleled knowledge and innovation to every project.

End-to-End Control:

As the only GFS tanks manufacturer that also produces enamel frit, we can adjust formulas to ensure the highest enameling quality.

Proven Track Record:

Successful projects in over 100 countries demonstrate our ability to deliver reliable solutions for diverse applications.

Comprehensive Support:

From design and engineering to installation and after-sales service, we provide end-to-end support to ensure project success.

Building a Sustainable Future

At Center Enamel, we are committed to advancing sustainable solutions that address global challenges in renewable energy and waste management. Our biogas tanks are not just products; they are part of a larger mission to create a cleaner, greener, and more sustainable world.

Partner with the Leading Biogas Tank Manufacturer in China

As the leading biogas tank manufacturer in China, we are dedicated to providing innovative, durable, and efficient solutions that meet the needs of our customers worldwide. Whether you are planning a small-scale biogas project or a large industrial plant, Center Enamel has the expertise and technology to support your vision.

Contact Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) today to learn more about our biogas tanks and how we can help you harness the power of biogas for a sustainable future.