-

Glass Fused To Steel Tanks (465)

-

Stainless Steel Tanks (434)

-

Fusion Bonded Epoxy Tanks (469)

-

Galvanized Steel Tanks (321)

-

Aluminum Dome Roofs (1257)

-

Wastewater Storage Tanks (226)

-

Welded Steel Tanks (457)

-

Pressure Vessels (295)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (270)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (173)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (146)

-

Biogas Projects (381)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (223)

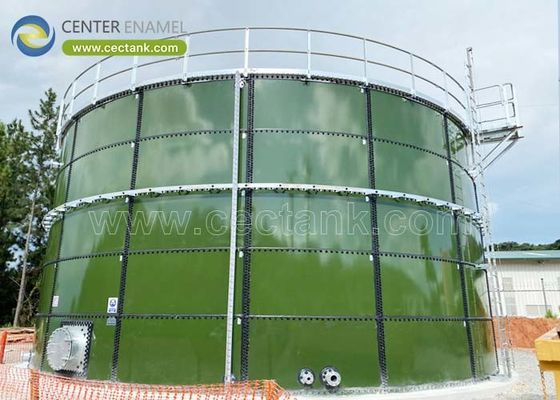

Factory Coated Bolted Storage Tanks for Anaerobic Digestion Applications

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W20160901010 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Factory Coated Bolted Storage Tanks for Anaerobic Digestion Applications

In the rapidly evolving field of renewable energy production and wastewater treatment, anaerobic digestion plays a crucial role. This biological process not only helps in the treatment of organic waste but also generates valuable biogas, a renewable energy source. To ensure the efficiency and longevity of anaerobic digestion processes, the storage tanks used must meet high standards of durability, corrosion resistance, and performance.

At Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), we specialize in providing Factory Coated Bolted Storage Tanks that are specifically designed to meet the demands of anaerobic digestion applications. Our bolted storage tanks, which feature a high-quality factory coating, offer exceptional strength, corrosion resistance, and ease of maintenance for wastewater treatment and biogas production projects.

What Are Factory Coated Bolted Storage Tanks?

Factory Coated Bolted Storage Tanks are tanks constructed from high-strength steel panels that are pre-coated with a durable, protective layer before assembly. Unlike traditional welded tanks, these bolted tanks are assembled on-site, offering significant advantages in terms of transportation, flexibility, and installation efficiency.

The coating applied to the steel panels during the factory process is designed to offer superior corrosion protection and to extend the life of the tank, even in aggressive environments like those found in anaerobic digestion applications.

As a leading storage tank manufacturer worldwide. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks Welded Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Bio gas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

Why Choose Factory Coated Bolted Storage Tanks for Anaerobic Digestion?

The anaerobic digestion process involves the breakdown of organic materials by bacteria in an oxygen-free environment, which produces biogas. During this process, the tank is exposed to various challenges, such as high humidity, corrosive gases, and high pressure. To withstand these harsh conditions, the storage tank needs to offer specific features, all of which are provided by Factory Coated Bolted Storage Tanks.

1. Superior Corrosion Resistance

One of the most critical factors in selecting tanks for anaerobic digestion applications is corrosion resistance. The presence of hydrogen sulfide (H₂S) and other acidic gases in the biogas produced can cause significant wear and tear on conventional steel tanks. Over time, this corrosion can lead to costly repairs and even failure of the tank.

Our Factory Coated Bolted Storage Tanks are coated with high-quality protective materials, such as fusion-bonded epoxy or glass-fused-to-steel (GFS) coatings, providing exceptional corrosion resistance. This means the tanks are built to withstand the acidic environment created by the anaerobic digestion process and resist the corrosive effects of biogas, ensuring the longevity and durability of your investment.

2. High Structural Integrity

Anaerobic digestion tanks need to be designed to handle high internal pressures and mechanical stresses that occur during the breakdown of organic materials. The bolted tank design of our factory-coated tanks allows for enhanced structural integrity without compromising flexibility.

Our tanks feature high-strength steel panels that are carefully engineered to provide the necessary structural support. The bolted assembly process enables easier on-site construction, making them ideal for large-scale projects. Whether you are looking to expand an existing system or design a new facility, our tanks can be customized to meet your specific operational and capacity requirements.

3. Cost-Effective and Easy Installation

Compared to traditional welded or concrete tanks, Factory Coated Bolted Storage Tanks offer a cost-effective solution for anaerobic digestion projects. The modular nature of these tanks allows for easy transportation and quick installation at the project site. The panels are factory-coated and pre-fabricated, reducing construction time and labor costs.

The bolted assembly also means that the tank can be easily dismantled and relocated if needed, providing flexibility for future modifications or expansions. This cost-effective design makes our tanks a popular choice for both new builds and existing anaerobic digestion systems that need upgrades or replacements.

4. Long-Term Durability and Low Maintenance

One of the most significant advantages of our Factory Coated Bolted Storage Tanks is their long-term durability. The factory-applied coating ensures that the tank is resistant to wear, corrosion, and harsh chemicals, leading to lower maintenance costs and less downtime.

Because our tanks are designed with a smooth, non-porous surface, there is less risk of sludge buildup or biofilm formation, reducing the need for regular cleaning and ensuring optimal operation. The coating also provides a longer lifespan, allowing your anaerobic digestion system to operate efficiently for years.

5. Environmental Sustainability

The anaerobic digestion process itself is inherently environmentally sustainable. It helps reduce organic waste, minimize landfill usage, and produce biogas as a renewable energy source. By choosing Factory Coated Bolted Storage Tanks, you are investing in a solution that supports environmental goals while benefiting from a high-performance system.

Our tanks are built using recyclable materials and have a minimal environmental footprint in both production and operation. The robust coating helps preserve the integrity of the tank over time, reducing the need for frequent replacements and conserving resources.

6. Customization and Flexibility

Every anaerobic digestion project has unique needs, which is why customization is critical. Center Enamel offers fully customizable bolted storage tanks that can be tailored to fit the specific needs of your biogas or wastewater treatment plant. Our engineers work closely with clients to design tanks that meet capacity requirements, site conditions, and any other project-specific needs.

From tank size and capacity to specialized coatings and design features, we ensure that your Factory Coated Bolted Storage Tanks are optimized for performance in your anaerobic digestion process.

Applications of Factory Coated Bolted Storage Tanks in Anaerobic Digestion

Factory Coated Bolted Storage Tanks are ideal for a variety of anaerobic digestion applications, including:

Municipal wastewater treatment: Handling sewage sludge and treating organic waste for biogas production.

Food and beverage industries: Managing organic waste from food production, such as fruit and vegetable processing, dairy, and meat processing plants.

Agricultural waste: Managing manure and other agricultural by-products through the anaerobic digestion process to generate biogas.

Industrial effluent treatment: Treating organic waste produced by industrial processes and converting it into renewable energy.

Why Choose Center Enamel’s Factory Coated Bolted Storage Tanks for Anaerobic Digestion

At Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), we pride ourselves on delivering high-quality and innovative solutions to our clients in the anaerobic digestion industry. Our Factory Coated Bolted Storage Tanks offer the perfect combination of corrosion resistance, durability, cost-effectiveness, and easy maintenance, making them the ideal choice for wastewater treatment and biogas production applications.

Whether you are upgrading an existing system or designing a new anaerobic digestion facility, our bolted storage tanks provide the reliability, flexibility, and long-term performance you need. With our commitment to quality and sustainability, Center Enamel is your trusted partner for anaerobic digestion solutions.

For more information on our Factory Coated Bolted Storage Tanks and how they can enhance your anaerobic digestion process, please contact us today. Let us help you take your wastewater treatment or biogas project to the next level.