-

Glass Fused To Steel Tanks (319)

-

Stainless Steel Tanks (365)

-

Fusion Bonded Epoxy Tanks (157)

-

Galvanized Steel Tanks (234)

-

Aluminum Dome Roofs (543)

-

Wastewater Storage Tanks (224)

-

Welded Steel Tanks (56)

-

Pressure Vessels (207)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (179)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (168)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (130)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (13)

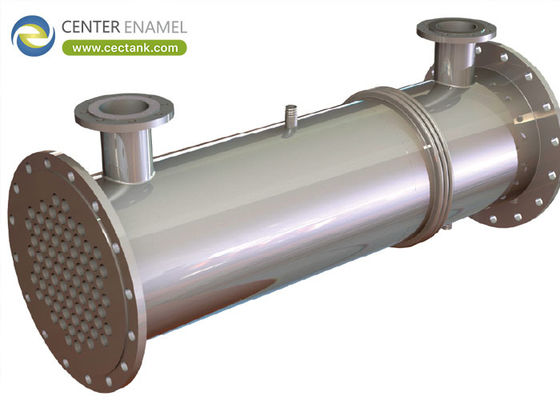

Center Enamel The Leading Pressure Vessel Heat Exchanger – Revolutionizing Thermal Efficiency Worldwide

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001,CE, NSF/ANSI 61, WRAS, ISO 28765, LFGB, BSCI, ISO 45001 |

| Minimum Order Quantity: | 1 Sets |

| Price: | 2000 |

| Delivery Time: | 2 months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets / days |

|

Detail Information |

|||

Product Description

| Attribute | Value |

|---|---|

| Material | steel or stainless steel |

| Color | Customized |

| Sizes | Customized |

| Design Standards | GB150-2011 |

| Applications | Chemical, pharmaceutical, petroleum and petrochemical, new energy industries |

| Products | Tanks, Pressure Vessels, Reactors, Heat Exchangers, Towers |

In the intricate dance of industrial processes, heat transfer is often the conductor, dictating efficiency, energy consumption, and product quality. At the heart of this thermal orchestration lies the heat exchanger - a critical pressure vessel designed to facilitate the controlled transfer of heat between fluids.

| Products | Pressure Vessel Types |

|---|---|

| Atmospheric Pressure Vessels | Horizontal Containers, Vertical Cylindrical Containers, Vertical Cylindrical Storage Tanks |

| Separator Pressure Vessels | Gravity Separator, Cyclone Separator, Coalescing Separator, Centrifugal Separator, Steam-water Separator, Bearing Separator, Mechanical Filter, Ion exchange Filter, Air Filter, Fuel Filter, Adsorption Filter, BioFilter, Oil Filter, Hydraulic oil Filter, Separator |

| Heat Exchangers | Shell and Tube Heat Exchangers, Plate Heat Exchangers, Spiral Heat Exchangers, Air Coolers, Liquid Coolers, Thermoelectric Coolers, Chill Water Main Unit, Evaporative Condensers, Air cooled Condensers, Electronic Gas Condensers |

| Reactor Pressure Vessels | Stirred Tank Reactors, Continuous Stirred-tank Reactors, Tubular Reactors, Tower Reactors, Fixed Bed Reactors, Fluidized Bed Reactors, Bioreactors |

-

Advanced Material Science for Demanding Environments:

Center Enamel leverages its profound understanding of materials science to select and utilize the most appropriate high-grade materials for pressure vessel heat exchangers, including stainless steel, carbon steel, and specialized coatings for corrosive applications.

-

Comprehensive Design and Engineering Capabilities:

Our team of highly skilled engineers possesses extensive knowledge in thermal dynamics, fluid mechanics, and mechanical design, allowing us to customize solutions that maximize heat transfer efficiency and operational performance.

-

State-of-the-Art Manufacturing and Quality Control:

Our manufacturing facilities are equipped with cutting-edge intelligent equipment, and each pressure vessel undergoes rigorous inspections and tests to verify structural integrity and performance capabilities.

-

Versatile Applications Across Diverse Industries:

Our heat exchangers serve critical roles in petrochemical, oil & gas, power generation, HVAC, food & beverage, pharmaceutical, and wastewater treatment industries.

-

Integrated Solutions and Global Reach:

We offer comprehensive support throughout the entire project lifecycle, from design to after-sales service, with successful projects across numerous countries and continents.

Center Enamel is not just manufacturing heat exchangers; we are providing the essential infrastructure that underpins thermal efficiency and operational excellence across the global industrial spectrum. Our dedication to superior engineering, advanced manufacturing, and uncompromised quality firmly establishes us as the leading China pressure vessel heat exchanger manufacturer, driving innovation and shaping a more energy-efficient future.