-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

Transforming Organic Wastewater Treatment Projects Into Environmental Excellence For Food Processing

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001:2008, AWWA D103 |

| Model Number: | W20161227006 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | Center Enamel |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 | Model Number | W20161227006 |

| Applications: | Water , Waste Water, Digester , Reactor , Grain , Sludge , Chemicals | Acid And Alkalinity Proof: | PH1 - PH14 |

| Usage: | Waste Water Treatment , Sewage Treatment, Effluent Treatment, Ect. | Defect Free: | Minimum Maintenance Needed |

| Installation: | By Jacking Machine Or Steel Pole, Fast In Installation | High Light: | Organic Wastewater Treatment Projects,Wastewater Treatment Projects For Food Processing |

Product Description

Green Solutions For Food Processing: Transforming Organic Wastewater Into Environmental Excellence

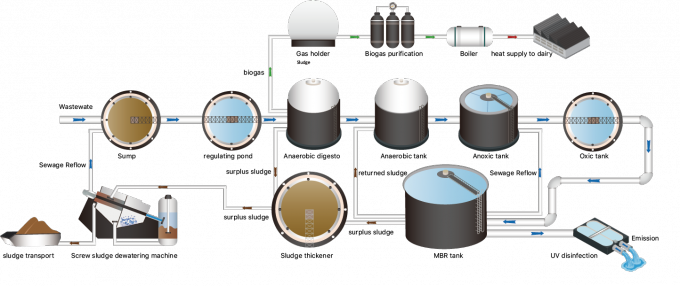

The outline of the organic wastewater treatment process in food processing encompasses various stages, including pre-treatment, biological treatment, physical-chemical treatment, and final treatment. Here is a brief overview, subject to adjustments based on the specific characteristics of different factories and wastewater:

Pre-treatment Stage:

1.1 Wastewater Collection: Gather organic wastewater produced from food processing production lines.

1.2 Solid Screening: Employ mechanical equipment (such as screens) to eliminate large solid particles and prevent damage to downstream treatment equipment.

1.3 Sedimentation Tank: Channel wastewater into a sedimentation tank to reduce suspended particle content through settling.

Biological Treatment Stage:

2.1 Activated Sludge Process: Introduce activated sludge microorganisms for aerobic biological treatment, converting organic substances into harmless byproducts.

2.2 Aeration Tank: Provide ample oxygen to microorganisms, facilitating the biological degradation process.

Physical-Chemical Treatment Stage:

3.1 Aeration-Clarification Tank: Combine aeration and clarification to further remove suspended solids and biological sludge.

3.2 Membrane Bioreactor (MBR): Utilize membrane filtration technology to separate biological sludge effectively, enhancing water treatment efficiency.

3.3 Activated Carbon Adsorption: Deploy activated carbon adsorption technology to eliminate residual organic matter and color.

3.4 pH Adjustment: Adjust the pH value based on wastewater characteristics to enhance subsequent treatment effects.

Final Treatment Stage:

4.1 Disinfection: Use methods like ultraviolet radiation or ozone treatment to disinfect the treated water, ensuring compliance with environmental standards.

4.2 Discharge or Reuse: Release treated water into the environment or recycle it through appropriate processes.

Monitoring and Control:

5.1 Set monitoring points at each treatment stage to track key parameters, ensuring system stability.

5.2 Automatic Control System: Integrate an automatic control system to real-time adjust treatment parameters to accommodate variations in water quality and flow.

Waste Handling:

6.1 Sludge Treatment: Employ technologies like dewatering and drying to reduce sludge volume, facilitating convenient disposal.

The wastewater generated from dairy processing primarily contains soluble organic compounds, including sugars, starch, proteins, and fatty acids. The wastewater is biodegradable, and free from toxic substances and large suspended particles, presenting a milky appearance. It falls under the category of medium to high-concentration wastewater.

The wastewater treatment project in the dairy industry involves pre-treatment of raw materials, hydrolysis and acidification, anaerobic treatment units, and combined ponds for biochemical treatment. These units are assembled on-site using our company's enamel-assembled tanks. The advantages include low cost, simple construction, short construction cycles, easy maintenance, and a neat and aesthetic appearance.

Zhongzhong Technology is a comprehensive high-tech enterprise specializing in the research, development, manufacturing, and sales of enamel-assembled tanks and diversified environmental protection equipment. The company's main business includes environmental protection EPC projects and undertaking anaerobic process sections. Throughout the project implementation, the company continuously invests in research and development, gathers scientific and technological forces, and forms a service system covering from R&D to after-sales, providing customized solutions for customers quickly and with high quality.

The evaluation criteria for projects not only need to meet technical and quality requirements but also transition towards overall standards of sustainability, quality improvement, energy conservation, and carbon reduction. Zhongzhong Technology actively responds to market and policy changes, empowering diversified environmental protection equipment manufacturing and environmental protection EPC projects with innovative research and development technology for GFS tanks. This is to meet diverse customer needs and project requirements. Today, Zhongzhong Technology's business covers areas such as kitchen waste, leachate, municipal sewage, biogas projects, breeding wastewater, industrial wastewater, drinking water, and fire-fighting water. In the future, the company's R&D achievements will be applied in more projects, striving to achieve a win-win situation of economic benefits, environmental benefits, and social benefits, promoting the high-quality development of the environmental protection industry.