-

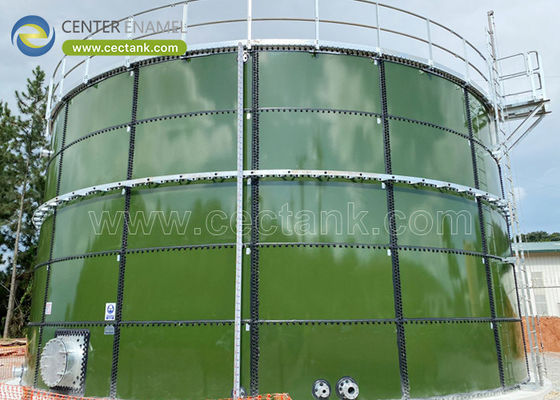

Glass Fused To Steel Tanks (319)

-

Stainless Steel Tanks (300)

-

Fusion Bonded Epoxy Tanks (123)

-

Galvanized Steel Tanks (175)

-

Aluminum Dome Roofs (520)

-

Wastewater Storage Tanks (224)

-

Welded Steel Tanks (27)

-

Pressure Vessels (156)

-

Anaerobic Digester (201)

-

Industrial Water Tanks (349)

-

Glass Lined Steel Tanks (180)

-

Bolted Steel Tanks (179)

-

Sludge Storage Tank (115)

-

Biogas Storage Tank (168)

-

Leachate Storage Tanks (133)

-

Agricultural Water Storage Tanks (179)

-

Fire Water Tank (166)

-

Grain Storage Silos (125)

-

Biogas Projects (349)

-

Wastewater Treatment Projects (270)

-

Double Membrane Roof (13)

Large Vitrum Bolted Enamel Grain Storage Silo Used In Farm With Cone Roof

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | J2016012705 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

Product Description

Large Vitrum Bolted Enamel Grain Storage Silo Used In Farm With Cone Roof

In modern agricultural practices, efficient grain storage solutions play a pivotal role in ensuring food security and economic stability. Among the array of storage options available, the Large Vitrum Bolted Enamel Grain Storage Silo with Cone Roof stands out as a hallmark of durability, efficiency, and innovation.

Shijiazhuang Zhengzhong Technology Co., Ltd.'s Vitrum Bolted Enamel Grain Storage Silo with Cone Roof exemplifies innovation and reliability in agricultural storage solutions. Engineered with precision and crafted for durability, these silos uphold the company's commitment to quality and sustainability, empowering farmers globally to safeguard their harvests and enhance productivity.

Overview of Vitrum Bolted Enamel Grain Storage Silo

The Vitrum Bolted Enamel Grain Storage Silo is engineered by Shijiazhuang Zhengzhong Technology Co., Ltd., a pioneering force in the realm of bolted storage solutions. These silos are crafted using advanced Glass-Fused-to-Steel (GFS) technology, combining the strength of steel with the corrosion-resistant properties of glass. This fusion ensures unparalleled longevity and reliability, making it an ideal choice for agricultural storage needs.

As a leading storage tank manufacturer in China. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

| Configuration of Customized Storage Tanks | ||||

| Storage tanks | Volume | Roofs | Application | Design Requirements |

|

GFS Tanks SS Tanks Fusion Bonded Epoxy Tanks Galvanized Steel Tanks |

<1000m³ 1000-10000m³ 10000-20000m³ 20000-25000m³ >25000m³ |

ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

Water Supply & Drainage System Seismic Design Wind Resistant Design Lightning Protection Design Tank Insulation Design |

WasteWater Treatment Project Equipment Supply

| Pretreatment Equipment | Resource Utilization System | Sludge Treatment System | Other Equipment |

|

Mechanical Bar Screen Solid-liquid Separator Submersible Mixer |

Gas Holder Boiler System Boost Fan Biogas Generator Torch System Dehydration and Desulfurization Tank |

PAM Integration Dosing Device Screw Sludge Dewatering Machine Slurry Separation Centrifuge |

Sewage Pump Mud Scraper Submersible Sewage Pump Three-phases Separator |

Key Features and Benefits

Glass-Fused-to-Steel Technology: The silo's interior surface is coated with enamel that is fused to the steel at high temperatures, creating a smooth, non-porous finish resistant to corrosion, chemicals, and extreme weather conditions.

Structural Integrity: Designed to withstand varying loads and environmental stresses, the silo's bolted panels provide structural stability, ensuring safe storage of grains without compromising on strength.

Cone Roof Design: The cone roof design enhances the silo's durability and functionality, optimizing the storage capacity while minimizing the risk of grain spoilage due to moisture buildup.

Customization Options: Available in a range of capacities and dimensions, each silo can be tailored to meet specific farm requirements, accommodating different grain types and volumes with ease.

Ease of Installation and Maintenance: Engineered for rapid installation, these silos offer cost-effective solutions without the need for extensive on-site construction. Maintenance is simplified due to the inert nature of the enamel coating, requiring minimal upkeep over its operational lifespan.

Applications

The Vitrum Bolted Enamel Grain Storage Silo finds widespread application across agricultural sectors worldwide:

Grain Storage: Ideal for storing maize, wheat, barley, rice, and other grains, preserving quality and nutritional value until market conditions are favorable.

Feed Storage: Suitable for storing animal feed, ensuring freshness and nutritional integrity.

Bio-Energy Storage: Used in the storage of biomass and biofuels, supporting renewable energy initiatives.

Center Enamel combines the excellent performance of various tanks to provide customers with solutions composed of diverse equipment combinations. This approach allows us to flexibly meet the needs and requirements of different application fields. Throughout the project construction process, the teams at Center Enamel collaborate closely, actively coordinate, and prioritize each step, conducting rigorous checks at every level to ensure the smooth completion of projects.

From being a leader in the Global GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.

For more information on how the Vitrum Bolted Enamel Grain Storage Silo can optimize your farm's storage capabilities, contact Shijiazhuang Zhengzhong Technology Co., Ltd. today. Discover why their solutions are trusted by agricultural professionals worldwide.