-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

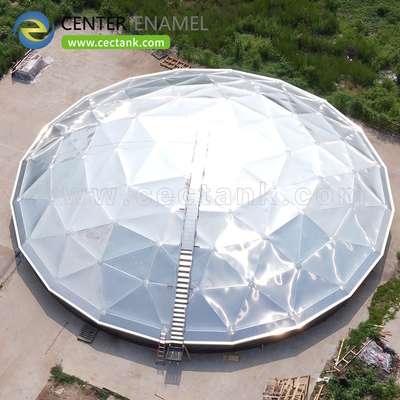

Pre Manufactured Clear Span Aluminum Dome Roofs

| Place of Origin: | China |

| Brand Name: | Center Enamel |

| Certification: | ISO 9001 |

| Model Number: | Aluminum Dome Roofs |

| Minimum Order Quantity: | 1 |

| Price: | 100-50000 |

| Packaging Details: | 2000 |

| Delivery Time: | 8 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000 |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | Center Enamel |

|---|---|---|---|

| Certification | ISO 9001 | Model Number | Aluminum Dome Roofs |

| Material: | Aluminum | Structure: | Self-supporting Structure |

| Corrosion Resistant: | High Corrosion Resistant | Maintenance: | Virtually Maintenance Free |

| Installation: | Quick Field Installation | Design: | Clear Span Design |

| High Light: | Clear Span Aluminum Dome Roofs,Pre Manufactured Aluminum Dome Roofs |

||

Product Description

Aluminum Geodetic dome Roof Installation

The advantage of the aluminum dome roof is that it does not require high-temperature work, and is pre-manufactured, and then shipped to the site in the form of parts, which only need to be assembled. The dome can be assembled with storage tanks, directly "in situ" the tank next to the water tank or shell support structure. If the storage tank remains in use when the dome is assembled and installed on the storage tank, the latter method is preferred. A typical application for water tanks to keep running during construction is wastewater tanks.

There are two construction methods, one is from the center cone/hub to the outside, and the other is from the outside to the center. Usually, when the space is limited, the dome will be directly installed on the supporting structure "in-situ". The "in-situ" construction process involves building a dome directly on the shell from the outside to the center.

When the Liqiong canopy is assembled inside the tank or next to the tank on the ground, a tripod or quadruped will be used to lift the dome of each layer during the installation process, which is convenient and safe for working on the ground and restricting high-altitude work. After the dome is built, it can be lifted to the top of the supporting structure using a winch or crane. This method ensures a safer and faster installation process.

weightlifting. The dome hoisting method will affect the installation time and equipment cost (such as cranes and chain hoists). Need to clarify at the beginning which method is feasible, because it will affect the timetable and cost of the project.

When the dome is assembled on the floor inside the water tank, the dome needs to be rigged to install it on the supporting structure. This lifting can be done in two ways; one is to use a chain hoist winch and pulley, and the second is to use a crane for rigging.

As an alternative, cranes are the least efficient method. However, in some cases, it requires the use of cranes when available. However, accidental factors such as breeze conditions can cause the light dome to shake too much for safe installation. In the picture, 26 of the four cranes are used to lift this dome from the inside of the tank into place.

Once the assembly process of the dome structure is completed in the tank, the installer will use the gripping winch and pulley system to effectively lift it to the top of the shell. It requires several chain hoists to be installed around the top of the tank shell so that the dome can be lifted into place.

The crane installation process involves assembling the dome on the ground next to the tank and then lifting it into place with a crane. In this way, the water tank and the dome can be built at the same time, saving precious time.

The initial cost of a steel cone roof is lower than that of an aluminum dome roof, but due to lower maintenance costs, cost savings can be achieved throughout the life of the dome. Rising steel prices and high labor costs have made aluminum domed roofs more attractive. Overall, in the life cycle of the dome compared to the life cycle of the steel cone roof, the dome is more cost-effective.